You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing 3/8 x 10 Mcdermott Joint pin?

- Thread starter tlayne

- Start date

The easiest way would be to cut the top couple of inches off the cut in a band saw. If you're looking to save the cue, then some heat on the pin. I use Vice Grips to turn the pin out.

I keep on trying..

I keep heating it very carefully and try to grip it good enough but the thing just wont break loose and I am not concerned with damaging the cue. I have heated and try to break this thing loose about 6 times. Tried a vise, and a couple other ideas. How are you getting a grip on the actual cue? Its a decent cue, just havent came up with any way of gripping it without f-ing this thing up. Thanks for your help Tony

I keep heating it very carefully and try to grip it good enough but the thing just wont break loose and I am not concerned with damaging the cue. I have heated and try to break this thing loose about 6 times. Tried a vise, and a couple other ideas. How are you getting a grip on the actual cue? Its a decent cue, just havent came up with any way of gripping it without f-ing this thing up. Thanks for your help Tony

I heat them with a torch for quite a while, then I grab the pin with the vice grips and use the floor and hold them with my feet while twisting the cue. You could try putting a soldering iron on the end of the cue and leaving it there for a while. Then you don't have to worry about the flame damaging the cue.

Thanks man, this is my first one and I really dont want to mess the cue up. Cae up with the idea of putting the screw in a big pipe wrench and using the ground to, that seems to be giving me the most leverage. I will heat longer and see what happens, Thanks a bunch.

It worked!!!!

Hey Tony, Thanks for your help. The key is to heat it for a longer period of time I guess. Minimal damage and that screw cam right out. Nothing noticeable and wont affect play. Next time it will be a cleaner job.

One more thing, my new pin is about a half inch shorter than the old one. Will this pose any problems? And whats the best kinda glue, just wanna make sure. Thank, Tony Layne

Hey Tony, Thanks for your help. The key is to heat it for a longer period of time I guess. Minimal damage and that screw cam right out. Nothing noticeable and wont affect play. Next time it will be a cleaner job.

One more thing, my new pin is about a half inch shorter than the old one. Will this pose any problems? And whats the best kinda glue, just wanna make sure. Thank, Tony Layne

Hey Tony, Thanks for your help. The key is to heat it for a longer period of time I guess. Minimal damage and that screw cam right out. Nothing noticeable and wont affect play. Next time it will be a cleaner job.

One more thing, my new pin is about a half inch shorter than the old one. Will this pose any problems? And whats the best kinda glue, just wanna make sure. Thank, Tony Layne

i was going to tell you,

wrap a wet cloth around the cue,

aim flame away from cue just on tip of pin OR use vice grips and heat the vice grips, it'll transfer the heat enough

did it messup the finish a little????

Complete

The finish is perfectly fine. Just the wood inside the collar got a little burnt but didnt crack the wood. Once the pin is in, you cant even tell. Plus I can always clean that up. Thanks guys. My first pin replacement job is complete, well almost. The funny thing about this is that the guy snapped the cue over his knee and snap the shaft but the pin was just bent. No other damage to the butt. Pretty cool that I could do this with the help from guys passing forward a little knowledge. Appreciate it and Thank you.

The finish is perfectly fine. Just the wood inside the collar got a little burnt but didnt crack the wood. Once the pin is in, you cant even tell. Plus I can always clean that up. Thanks guys. My first pin replacement job is complete, well almost. The funny thing about this is that the guy snapped the cue over his knee and snap the shaft but the pin was just bent. No other damage to the butt. Pretty cool that I could do this with the help from guys passing forward a little knowledge. Appreciate it and Thank you.

Congratulations!

It's always hardest the first time. Nice job!

It's always hardest the first time. Nice job!

What is the easiest way to remove a 3/8 x 10 Mcdermott Joint pin? Please reply.

I normally heat the pin with a torch until I see a little smoke start coming off the wood where it meets the pin. Then I place the cue pin down in a table mounted vise and turn the pin out. It is normally very easy because of the leverage you can get doing it this way.

Hope this helps.

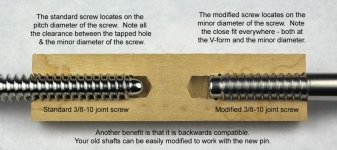

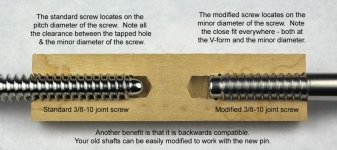

Excuse me for asking this question on your thread but it seems to relate. The origional poster mentioned a difference in pin length and from the looks of it the replacement pin has a different thread profile (is that a surgical pin?). Does this pose problems when fitting a new shaft? For instance would a McDermott G or I type shaft work as is or would you as cuemakers need to use a blank? Would the air gap in the "standard reeplacement shaft" matter and would the fitt be excessively tight?

It looks the same to me, just a different style of pin. He knew the pin he was taking out was a 3/8-10, so I doubt he would have tried to force a 3/8-11 pin into the same hole. And if he had, he probably would have asked here.

As for the gap, I would probably plugged the hole and retapped it to the correct depth. You could have also put some extra epoxy in the hole to hopefully fill that void. I'm sure there are plenty of cues out there with holes too deep, so unless it's abused, I imagine it will hold up.

As for the gap, I would probably plugged the hole and retapped it to the correct depth. You could have also put some extra epoxy in the hole to hopefully fill that void. I'm sure there are plenty of cues out there with holes too deep, so unless it's abused, I imagine it will hold up.

It looks the same to me, just a different style of pin. He knew the pin he was taking out was a 3/8-10, so I doubt he would have tried to force a 3/8-11 pin into the same hole. And if he had, he probably would have asked here.

As for the gap, I would probably plugged the hole and retapped it to the correct depth. You could have also put some extra epoxy in the hole to hopefully fill that void. I'm sure there are plenty of cues out there with holes too deep, so unless it's abused, I imagine it will hold up.

for the gap, I would probably plugged the hole and retapped it to the correct depth. You could have also put some extra epoxy in the hole to hopefully fill that void. I'm sure there are plenty of cues out there with holes too deep, so unless it's abused, I imagine it will hold up.

I am with you Tony, I would also plugg and retap the hole, in my opinion doing anything less would be asking for problems. I normally use canvas Phenolic rod for my plugs, it glues up well, holds thread great, and it is stronger than wood.

Take care Tony

Thank you I figured the depth gap would be handled something like that but the thread fit question was a reference something I remembered from an old thread. This pic explains the visual difference

I borrowed the pic from this thread... http://forums.azbilliards.com/showthread.php?t=135749

I borrowed the pic from this thread... http://forums.azbilliards.com/showthread.php?t=135749

There are a number of ways of removing bent broken pins. The easiest and most dangerous is to heat with a torch which is the way most do. The best way was described by someone who has a tool that electrically heated the pin so quickly that it never affected the surrounding wood but it cost something like 600.00. Not a toy that I would like to buy. Others use a soldering gun which is slow and once I had to bore the pin out with an end-mill. Thomas Wayne once described a safe way to remove a pin and is accomplished by what is called "friction welding". By cutting the pin off near the joint, drilling a hole into the stub about an 1 1/2 deep with about a 7/32 bit. You now take a 1/4" bit and counter drill about a 1 1/4 deep. You now remove the drill bit and reverse it in the drill chuck in your tail stock and insert the end into this counter bored hole. Now, with the lathe in reverse and the tail stock released from the bed so that it can move freely, you put hand pressure on the back of the tail stock forcing the bit into the bottom of this bored hole. This will create a lot of friction between the bit and the stud. When the bit gets red from friction you just release the hand pressure from the back of the tail stock. Now the friction ceases, the bit and stud cool and now they weld themselves to each other. The heat created melts the glue and since the lathe is running in reverse, the stud will screw itself out. This certainly is not the quickest way but it is the safest economical way.

Dick

Dick

It's always hardest the first time. Nice job!

Yeah, because you don't know what to expect. The first time is always a mystery. Actually, years down the road, some pins will fight with you like the first one. Mcd. sets their pins particularly well. I find them to be some of the toughest to remove.

I'll state my method and maybe something can be shared.

I chuck the cue in my metal lathe, soft collet for protection of course.

Even out of gear, my lathe will freewheel (rotate slowly on it's own).

I have an aluminum disc about 3" dia. x .090" thick with a hole in the center that I slide over the pin to protect the joint from excessive heat.

I also have an air-line mounted on the back-side of my lathe that provides a steady stream of cool air on the joint as the cue is rotating and it's pin is being heated. The aluminum disc deflects the flame away from the cue and dissipates heat.

Once I've seen enough smoke come out from around the pin to suggest to me that it's 'time', I stop the lathe, lock-in the backgear and apply my little Vise-Grips to the very end of the pin. With a little effort and a lot of luck, the pin will start to move. I can let the lathe hold the cue, it's not going anywhere. That leaves both my hands free to work the pin. When first clamped on to the pin, try moving it in both directions to break-down the epoxy. If at first you don't succeed, try, try again. Repeat as necessary.

tlayne,

Great job BTW. Betcha can't wait for the next one.

Please take this a suggestion only, though it will more likely open a can of worms.

On the big pins particularly, you want to see 1" of exposed thread, minimum.

It doesn't matter the thread count.

I'd be pleased if someone, somewhere got something from my writing, LoL.

SW style 3/8 x 10

I bought this pin from Brianna, he had them on sale so I thought I would try the brass sw style 3/8 x 10. when I dri-fit the pin it fits very nice, I kinda like the look and the price I got them for. Thanks to everyone here who had offered advice, i think my first minor repair is a success. Without the help Iwas sure to mess something up beyond repair. I just have one more question. How much of a difference do you think the hit will be coming from stainless steel to brass?

I bought this pin from Brianna, he had them on sale so I thought I would try the brass sw style 3/8 x 10. when I dri-fit the pin it fits very nice, I kinda like the look and the price I got them for. Thanks to everyone here who had offered advice, i think my first minor repair is a success. Without the help Iwas sure to mess something up beyond repair. I just have one more question. How much of a difference do you think the hit will be coming from stainless steel to brass?

Yeah, because you don't know what to expect. The first time is always a mystery. Actually, years down the road, some pins will fight with you like the first one. Mcd. sets their pins particularly well. I find them to be some of the toughest to remove.

I'll state my method and maybe something can be shared.

I chuck the cue in my metal lathe, soft collet for protection of course.

Even out of gear, my lathe will freewheel (rotate slowly on it's own).

I have an aluminum disc about 3" dia. x .090" thick with a hole in the center that I slide over the pin to protect the joint from excessive heat.

I also have an air-line mounted on the back-side of my lathe that provides a steady stream of cool air on the joint as the cue is rotating and it's pin is being heated. The aluminum disc deflects the flame away from the cue and dissipates heat.

Once I've seen enough smoke come out from around the pin to suggest to me that it's 'time', I stop the lathe, lock-in the backgear and apply my little Vise-Grips to the very end of the pin. With a little effort and a lot of luck, the pin will start to move. I can let the lathe hold the cue, it's not going anywhere. That leaves both my hands free to work the pin. When first clamped on to the pin, try moving it in both directions to break-down the epoxy. If at first you don't succeed, try, try again. Repeat as necessary.

tlayne,

Great job BTW. Betcha can't wait for the next one.

Please take this a suggestion only, though it will more likely open a can of worms.

On the big pins particularly, you want to see 1" of exposed thread, minimum.

It doesn't matter the thread count.

I'd be pleased if someone, somewhere got something from my writing, LoL.

Thank you KJ, appreciate you taking the time to reply. I am very new at this stuff so without the help and insight from you guys I was sure to overlook a few important details. The 1 inch rule, I didnt know and that you. What kind of glue/epoxy do you use in setting your pins, just curious. This McDermott was definitely tough. Thank you, Tony

There are a number of ways of removing bent broken pins. The easiest and most dangerous is to heat with a torch which is the way most do. The best way was described by someone who has a tool that electrically heated the pin so quickly that it never affected the surrounding wood but it cost something like 600.00. Not a toy that I would like to buy. Others use a soldering gun which is slow and once I had to bore the pin out with an end-mill. Thomas Wayne once described a safe way to remove a pin and is accomplished by what is called "friction welding". By cutting the pin off near the joint, drilling a hole into the stub about an 1 1/2 deep with about a 7/32 bit. You now take a 1/4" bit and counter drill about a 1 1/4 deep. You now remove the drill bit and reverse it in the drill chuck in your tail stock and insert the end into this counter bored hole. Now, with the lathe in reverse and the tail stock released from the bed so that it can move freely, you put hand pressure on the back of the tail stock forcing the bit into the bottom of this bored hole. This will create a lot of friction between the bit and the stud. When the bit gets red from friction you just release the hand pressure from the back of the tail stock. Now the friction ceases, the bit and stud cool and now they weld themselves to each other. The heat created melts the glue and since the lathe is running in reverse, the stud will screw itself out. This certainly is not the quickest way but it is the safest economical way.

Dick

Thank you for the reply. As for the tools end of it, I am just starting out. My first and biggest piece is the Cuesmith Deluxe. I actually used the biggest pipe wrench and a Bernzomatic Torch MAP.The pipe wrench worked really well after struggling to get leverage, it was awkward and I couldn't get a good grip. Sooner or later I will have alll the necessary tools needed. Thanks again, Tony

Last edited: