perfectpocketz

Banned

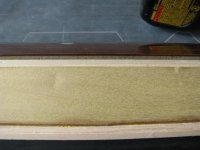

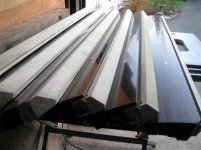

Glen has got the perfect formula, and special tooling to make any pool table play absolutely dead nuts perfect.....no spring in the rails....no dead hits.....no banking short. I just did a 7ft. Diamond smart table last night for a player to gamble high on....he wanted me to put Championship cushions on the table...he said I have the same table at home with those cushions on, and it plays better then any table in the country.

I told him Glen and I are working on the perfect way to make all the tables play the same with any cushion.

I also told the guy that I wouldn't replace the cushions with anything but the Diamond black cushion from the factory. The guy said then there is no way you can make the table play as good as mine...I said I'll make the table play better than yours at home. He said not possible....well we just have to find out when I'm done.

I'm done... he wins big....after 6 hrs. of play he comes over to me and says, I have to hand it to you...this table is the best playing table I've ever played on.

Everyone in the poolroom hit some balls on the table and just absolutely loved the table.

Thank you Glen for the info, and the special tooling you had me build to make this the best a table can play.

The guy paid for the job, and tipped on top after the match....said I was going to tip you for a perfect table....win or lose.

Wow...what a great playing Diamond Table....:smile::smile::smile:

Thank you Glen for your help, and tooling advice.....:grin-square::grin-square:

Mark Gregory

I told him Glen and I are working on the perfect way to make all the tables play the same with any cushion.

I also told the guy that I wouldn't replace the cushions with anything but the Diamond black cushion from the factory. The guy said then there is no way you can make the table play as good as mine...I said I'll make the table play better than yours at home. He said not possible....well we just have to find out when I'm done.

I'm done... he wins big....after 6 hrs. of play he comes over to me and says, I have to hand it to you...this table is the best playing table I've ever played on.

Everyone in the poolroom hit some balls on the table and just absolutely loved the table.

Thank you Glen for the info, and the special tooling you had me build to make this the best a table can play.

The guy paid for the job, and tipped on top after the match....said I was going to tip you for a perfect table....win or lose.

Wow...what a great playing Diamond Table....:smile::smile::smile:

Thank you Glen for your help, and tooling advice.....:grin-square::grin-square:

Mark Gregory