A cuemaker as well as billiard supply dealer showed me why he prefers not to use Predator or Tiger shafts. As you can see from the following I will always stick with OB-1 or OB-2 shafts.

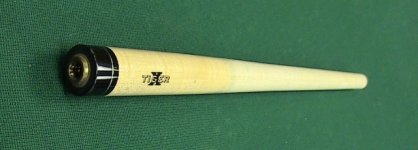

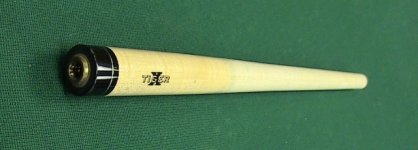

Tiger shaft

Predator shaft 314

The cue maker took a one shaft of each and cut them in half to see how accurate the shafts are made and to his surprise and mine, THIS is what we discovered about these highly requested shafts. I hope this isnt true for all of them. But geez look at how aweful that is.

Tiger shaft

Predator shaft 314

The cue maker took a one shaft of each and cut them in half to see how accurate the shafts are made and to his surprise and mine, THIS is what we discovered about these highly requested shafts. I hope this isnt true for all of them. But geez look at how aweful that is.

Last edited: