I have an A2 steel shaft taper bar not being used. It is 1" wide (1.002-1.003), 1/2" high, and 31" long. There are 5 locating holes. The two at the ends are 29" apart, with the other 3 evenly spaced in the middle.

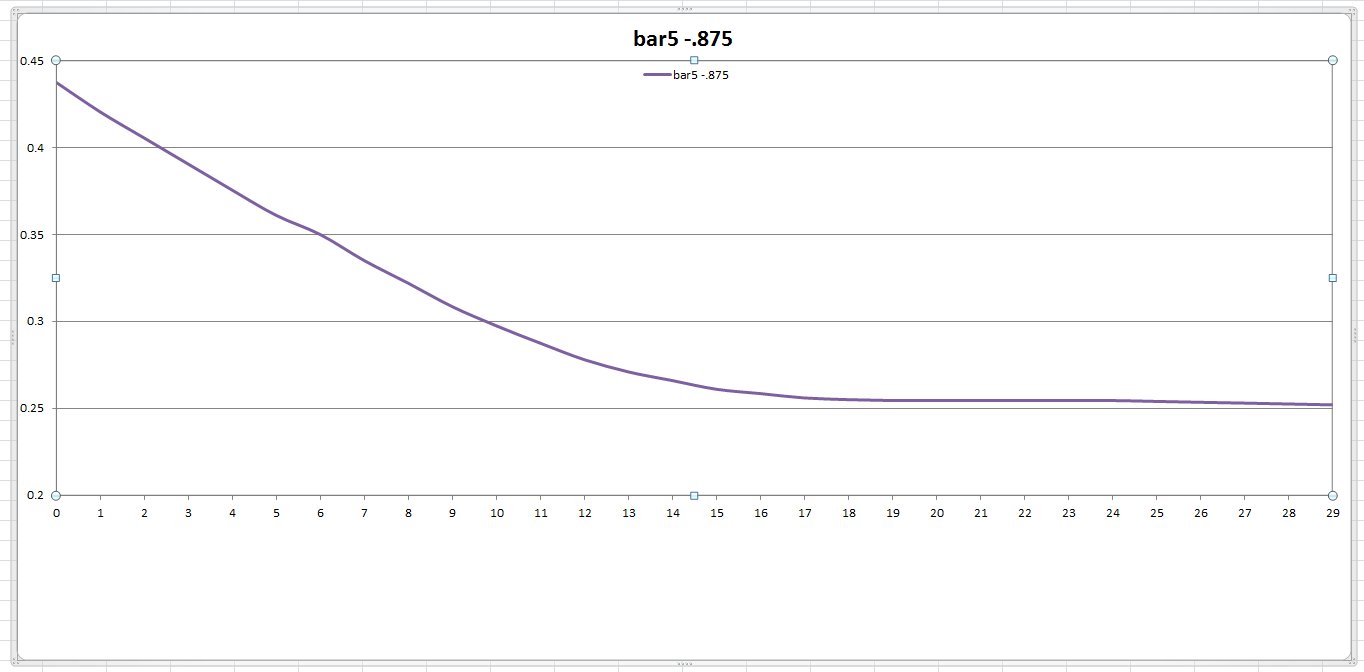

Below is a graph showing measurements of a shaft cut with this bar set to cut .504 at the tip and .875 at the joint, 29" length. If a shaft was cut to 13mm, then the joint would naturally be around .885. It is a fairly typical pro taper shaft. The setting used for the graph has a very small diameter increase the first 11-12 inches. The joint is left oversized with this bar, but not extremely so. I have also included the actual diameter measurements of the test shaft below the graph. The curve drawn through the data points is a spline, with no adjustments to the diameter measurements.

The bar was professionally machined by Bob Dzuricky. The profile is cut ON BOTH SIDES of the bar. You can push against it or pull on the back side regardless of orientation. The locating holes are 3/8" in diameter. 3/8" shoulder bolts can be used (with accurate drilling and tapping of a fixed base) to remove and replace the bar to the same location, or the bar can be fastened with normal 5/16" bolts and once indicated in left or used in tandem with fixed indicators for easy adjustment.

It may be obvious, but the bar can be set to leave more meat at the joint end resulting with a stiffer taper. Even though it is A2 steel, you could also torque the tip end of the bar a little after securing the first 4 bolts to make a slight adjustment the first 7-8 inches from the tip end.

A plain 36" ground A2 steel bar by itself is an easy $75 plus shipping from the metal supply places.

SOLD

0.875

0.841

0.811

0.781

0.751

0.722

0.7

0.67

0.644

0.617

0.595

0.575

0.556

0.542

0.532

0.522

0.517

0.512

0.51

0.509

0.509

0.509

0.509

0.509

0.509

0.508

0.507

0.506

0.505

0.504

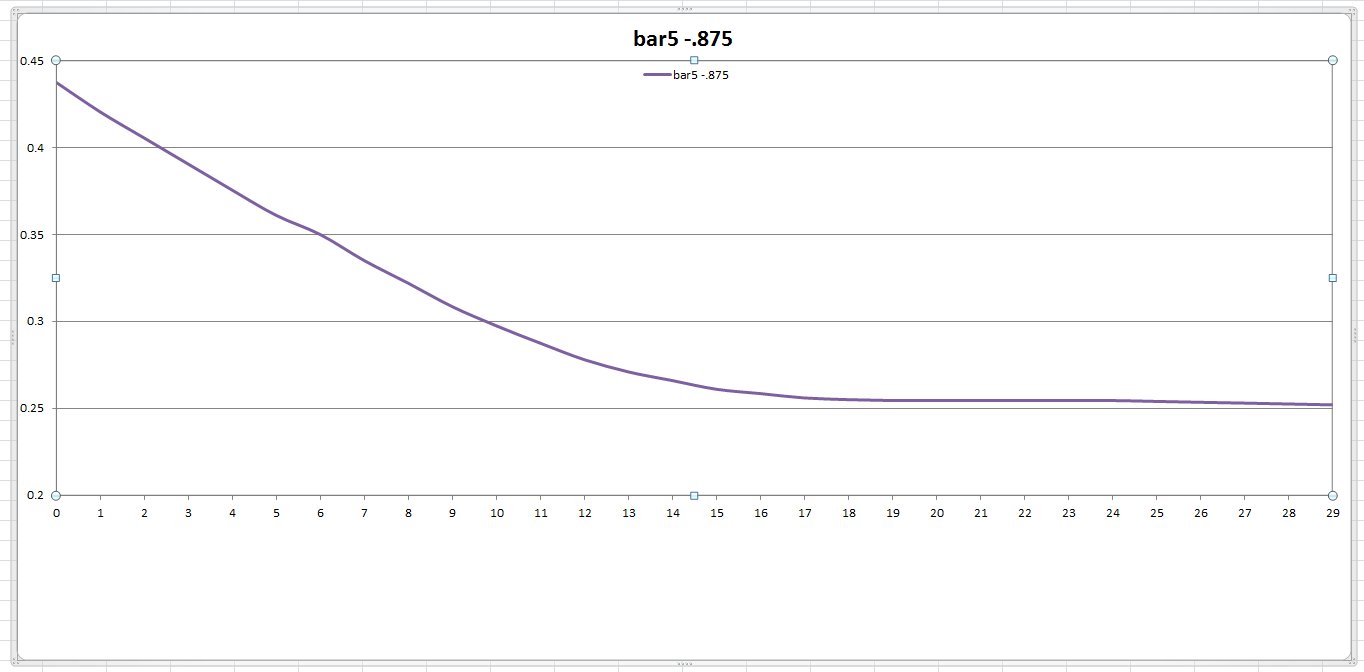

Below is a graph showing measurements of a shaft cut with this bar set to cut .504 at the tip and .875 at the joint, 29" length. If a shaft was cut to 13mm, then the joint would naturally be around .885. It is a fairly typical pro taper shaft. The setting used for the graph has a very small diameter increase the first 11-12 inches. The joint is left oversized with this bar, but not extremely so. I have also included the actual diameter measurements of the test shaft below the graph. The curve drawn through the data points is a spline, with no adjustments to the diameter measurements.

The bar was professionally machined by Bob Dzuricky. The profile is cut ON BOTH SIDES of the bar. You can push against it or pull on the back side regardless of orientation. The locating holes are 3/8" in diameter. 3/8" shoulder bolts can be used (with accurate drilling and tapping of a fixed base) to remove and replace the bar to the same location, or the bar can be fastened with normal 5/16" bolts and once indicated in left or used in tandem with fixed indicators for easy adjustment.

It may be obvious, but the bar can be set to leave more meat at the joint end resulting with a stiffer taper. Even though it is A2 steel, you could also torque the tip end of the bar a little after securing the first 4 bolts to make a slight adjustment the first 7-8 inches from the tip end.

A plain 36" ground A2 steel bar by itself is an easy $75 plus shipping from the metal supply places.

SOLD

0.875

0.841

0.811

0.781

0.751

0.722

0.7

0.67

0.644

0.617

0.595

0.575

0.556

0.542

0.532

0.522

0.517

0.512

0.51

0.509

0.509

0.509

0.509

0.509

0.509

0.508

0.507

0.506

0.505

0.504

Last edited: