I think this will cost too much right ?

Worth the cost.

Finding some one to do it correctly is the hardest part.

I don't understand really what the difference between the shims and adding wood the sub-rail.

Adding a piece of high quality, hardwood plywood to the end of the rail is to lengthen it.

Find it in a hobby model store.

The neoprene rubber shim is too protect the wood from ball damage.

http://www.ebay.com/itm/Pool-Table-Rail-Large-Cushion-Facings-3-16-Thick-/262482274254

Too thick a rubber shim makes the pocket "dead".

Recipe for tightening pockets for:

4 1/2" corner Pockets

5" Side Pockets

Correct Angles If Needed

Add 1/8" high quality hardwood plywood

3/16" Duro 60 high strength neoprene

Corner pocket angles of 141 or 51 degrees

Side pocket: 102 degrees or 12 degrees

Some like 4 3/8" pockets.

Use 3/16" plywood instead of 1/8"

You want Krazy Tight 4" 1/4" pockets?

use 1/4" plywood

what means by correct any pocket angle issues ?!

The correct angles are for ball reaction in the pocket and acceptance of ball. Not being "spit out" or "rattle" between ends.

I think i need more information to try to understand more.

Yes, search the web. PM me.

I didn't understand really what means by castings are not seated to the ends of the rails?

Needs to be No Space between metal and wood. Casting is in correct place next to back/front edge of rail.

WPA Specs:

9. POCKET OPENINGS AND MEASUREMENTS

Only rubber facings of minimum 1/16 [1.5875 mm] to maximum ¼ inch [6.35 mm] thick may be used at pocket jaws. The WPA-preferred maximum thickness for facings is 1/8 inch [3.175 mm]. The facings on both sides of the pockets must be of the same thickness. Facings must be of hard re-enforced rubber glued with strong bond to the cushion and the rail, and adequately fastened to the wood rail liner to prevent shifting. The rubber of the facings should be somewhat harder than that of the cushions.

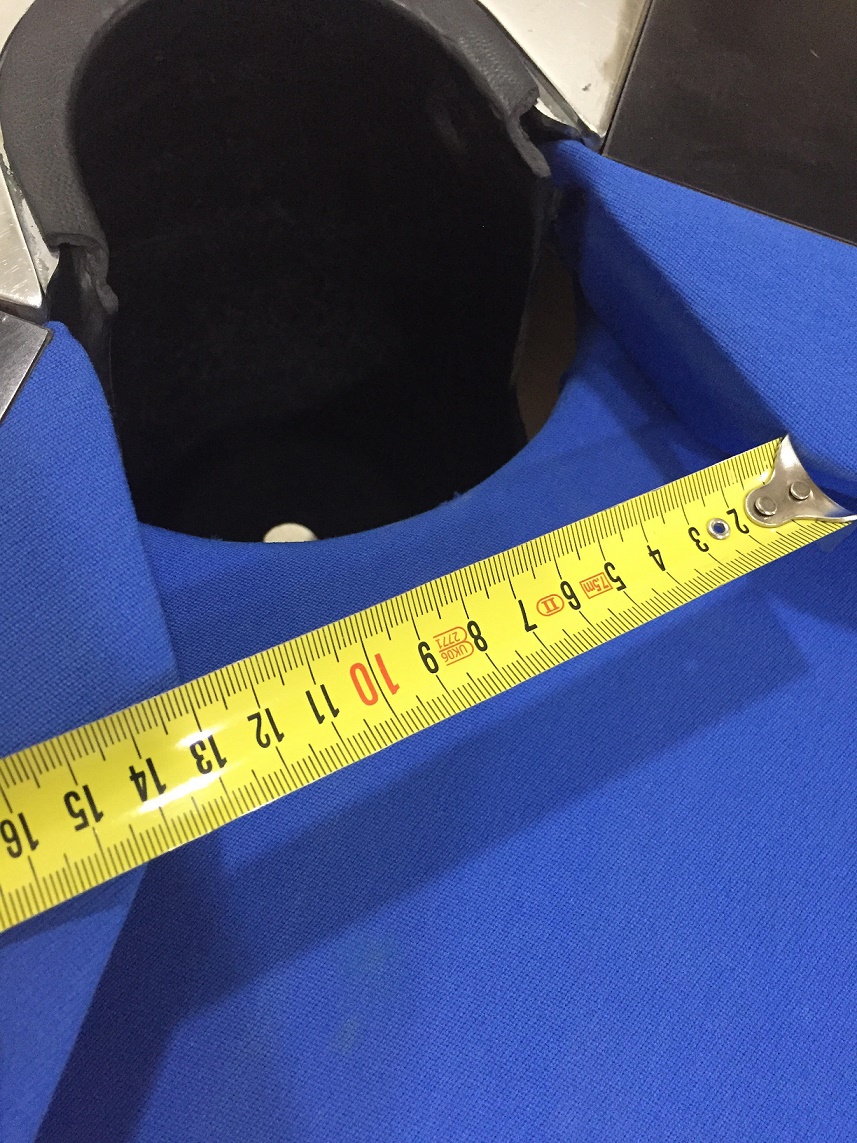

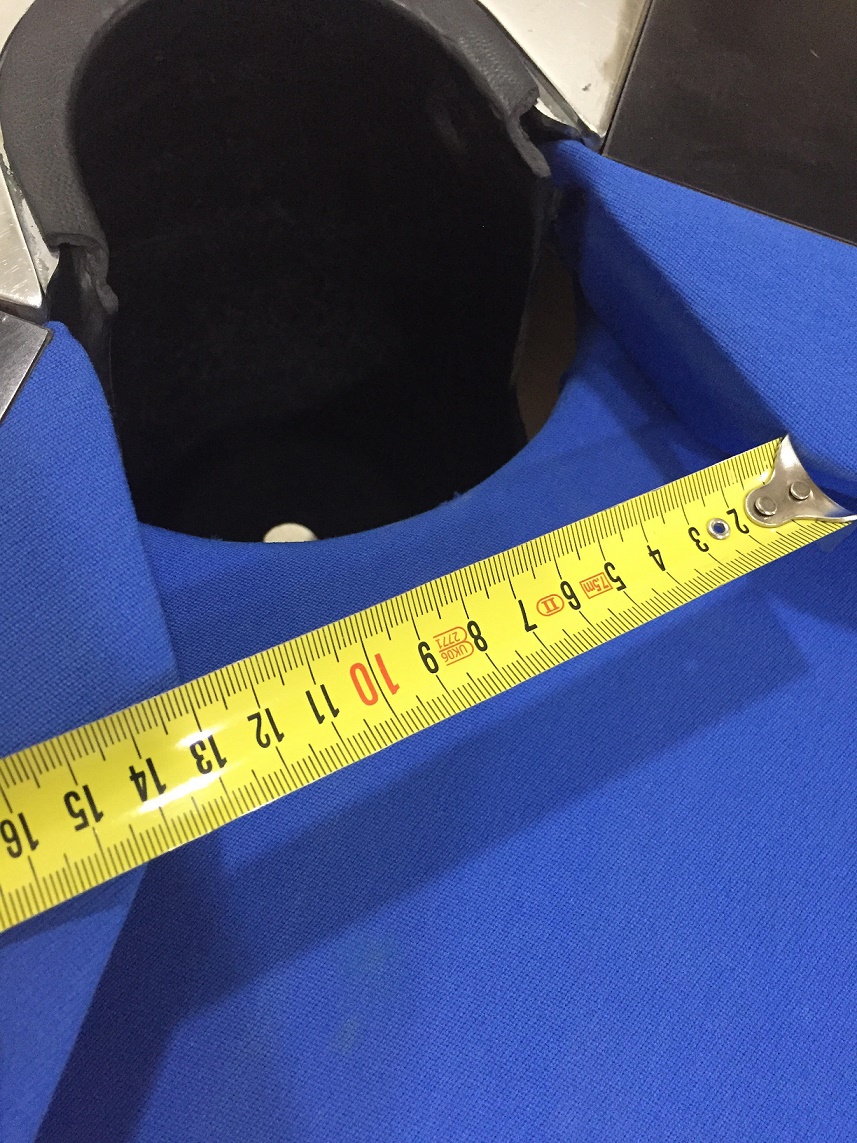

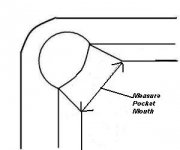

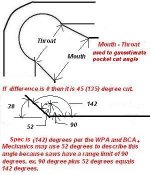

The pocket openings for pool tables are measured between opposing cushion noses where the direction changes into the pocket (from pointed lip to pointed lip). This is called mouth.

Corner Pocket Mouth: between 4.5 [11.43 cm] and 4.625 inches [11.75 cm]

Side Pocket Mouth: between 5 [12.7 cm] and 5.125 inches [13.0175 cm]

*The mouth of the side pocket is traditionally ½ inch [1.27 cm] wider than

the mouth of the corner pocket.

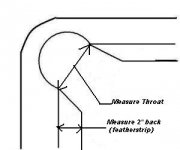

Vertical Pocket Angle (Back Draft): 12 degrees minimum to15 degrees maximum.

Horizontal Pocket Cut Angle: The angle must be the same on both sides of a pocket entrance. The cut angles of the rubber cushion and its wood backing (rail liner) for both sides of the corner pocket entrance must be 142 degrees (+1). The cut angles of the rubber cushion and its wood backing (rail liner) for both sides of the side pocket entrance must be 104 degrees (+1).

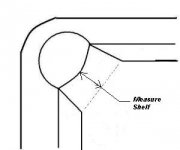

Shelf: The shelf is measured from the center of the imaginary line that goes from one side of the mouth to the other – where the nose of the cushion changes direction – to the vertical cut of the slate pocket cut. Shelf includes bevel.

Corner Pocket Shelf: between 1 [2.54 cm] and 2 ¼ inches [5.715 cm]

Side Pocket Shelf: between 0 and .375 inches [.9525 cm]