You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

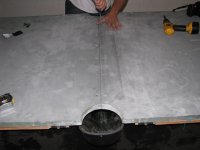

Had to cut the slate in half to get this ProAm installed!

- Thread starter realkingcobra

- Start date

Hey Glen - nice job! Did you know about the location beforehand or was it a surprise?

Will the built-in leveling system still work the same or do you stand a chance of harming your slate job?

I really don't know much about the Diamond leveling system.

--Jeff

Will the built-in leveling system still work the same or do you stand a chance of harming your slate job?

I really don't know much about the Diamond leveling system.

--Jeff

Hey Glen - nice job! Did you know about the location beforehand or was it a surprise?

Will the built-in leveling system still work the same or do you stand a chance of harming your slate job?

I really don't know much about the Diamond leveling system.

--Jeff

I kind of...sort of...knew about the location, but the angles of the pictures I looked before hand were nothing compared to actually SEEING the hole,...I mean stairs the slate was expected to go down, so it wasn't reaaaaaaally a surprise, so I guess I kind of expected it

If I'd have installed a 3 piece slate on this ProAm, yes I'd have lost the Diamond leveling system as it won't work with the 3 piece slate, so my choice was to take the hard way of doing things and cut the slate, and still be able to use the 26 point leveling system.

Once the slates put back together again, it's like it was never cut in half, so it all works out in the end, as I can still pick the slate up from the ends like it was a normal one piece slate

How are you doing in retirement buddy?

Hey Glen,

I'm doing great. Playing pool and doing some photography and traveling a bit.

It is as good as you said it would be!!!

No Diamonds over here that I have found! Brunswick Metros and Gold Crowns and a few other assorted manufacturers.

Too bad really!!!

--Jeff

I'm doing great. Playing pool and doing some photography and traveling a bit.

It is as good as you said it would be!!!

No Diamonds over here that I have found! Brunswick Metros and Gold Crowns and a few other assorted manufacturers.

Too bad really!!!

--Jeff

Pretty remarkable to put a pool table down that hole. Nice work Glen and Zach! :thumbup2:

Glen, you have no fear - you'd tackle anything. Is that bondo you used to seal the seam and screw holes?

If I'd have installed a 3 piece slate on this ProAm, yes I'd have lost the Diamond leveling system as it won't work with the 3 piece slate, so my choice was to take the hard way of doing things and cut the slate, and still be able to use the 26 point leveling system.

Once the slates put back together again, it's like it was never cut in half, so it all works out in the end, as I can still pick the slate up from the ends like it was a normal one piece slate

Can you elaborate on this a bit? Why is it possible to use the leveling system on a 2 piece slate but not a 3 piece? Why couldn't the same process be used in both cases? Why can you pick the slate up from both ends now? If both pieces are stuck back together now, won't that make it difficult to take out in the future?

I know nothing about tables, btw.

Glen, you have no fear - you'd tackle anything. Is that bondo you used to seal the seam and screw holes?

Yep, it sure is. I'm breaking Zach in just right:grin:...no sense in starting him out soft when it comes to setting up Diamonds, these pictures are of the table install just before this one, and only Zach's second install:grin::grin:

Didn't have to cut the slate in half on this one, but still managed to get a Diamond 7ft ProAm up them stairs and into the house...but not before asking the owner if he wouldn't just rather change his hobby to playing darts instead of pool:grin:

Super job..... What type of blade did you have to use to get that clean of a cut ? A thin carbide, I'm assuming but I want the answer from the master.

What size holes did you drill and did you counter sink them ? Any particular screws ? Also what the other person asked, what did you use to fill the holes and seam ?

What size holes did you drill and did you counter sink them ? Any particular screws ? Also what the other person asked, what did you use to fill the holes and seam ?

Yep, it sure is. I'm breaking Zach in just right:grin:...no sense in starting him out soft when it comes to setting up Diamonds, these pictures are of the table install just before this one, and only Zach's second install:grin::grin:

View attachment 148377

View attachment 148379

Didn't have to cut the slate in half on this one, but still managed to get a Diamond 7ft ProAm up them stairs and into the house...but not before asking the owner if he wouldn't just rather change his hobby to playing darts instead of pool:grin:

Those stairs look like a challenge but unless there covered with snow and ice I don't see you having a problem:grin:.

Why is it possible to use the leveling system on a 2 piece slate but not a 3 piece?

When a 3 piece slate is used, it's mounted to the frame of the table with wood screws. After the table is all put together and the cloth installed, in order to use the leveling system at that point, you'd have to be able to get back to the heads of the screws to loosen them up a little if you have to adjust the level of the slates at the seams, of which are now under the cloth and inaccessible to do so. So, until we come up with another way of mounting a 3 piece slate on a ProAm, the leveling system is not going to work.

Why can you pick the slate up from both ends now?

Because I splinted the slates back together with 2" flatbar steel and machine screws, superglued the slates together, then bondoed over the machine screw holes, so it's like it was never cut in half.

If both pieces are stuck back together now, won't that make it difficult to take out in the future?

No, as I can take the slates back apart again if need be:grin:

Super job..... What type of blade did you have to use to get that clean of a cut ? A thin carbide, I'm assuming but I want the answer from the master.

What size holes did you drill and did you counter sink them ? Any particular screws ? Also what the other person asked, what did you use to fill the holes and seam ?

Cutting slate, marble, concrete is all done on a daily basis, so it's nothing new. Saw blades are made just for this type of application, but they're diamond edged cutting blades, not carbide. I used the size holes that fit the screws, and yes they were counter sunk

Glen

Then, you simply put it back together againGreat work Zach, you're learning like a sponge buddy, hope Arizona is going to be ready for you when you're finished with school

View attachment 148357

View attachment 148358

View attachment 148359

View attachment 148360

View attachment 148361

Bear in mind before answering (even if you do) - I understand certain trade expertise cannot be shared - that my familiarity of this table, it's construction, and leveling system is somewhat lacking. :smile:

I'm curious....what type of anchoring system are you attaching to the back of the slate? or is the slate being directly anchored to the undercarriage of the table? Is the rigidity or the original manufacturer's intended design compromised by splitting the one-piece slate in half?

Engineering minds wanna know! :smile:

Steve H

Awesome custom job. Good thinking on the fly. :smile: