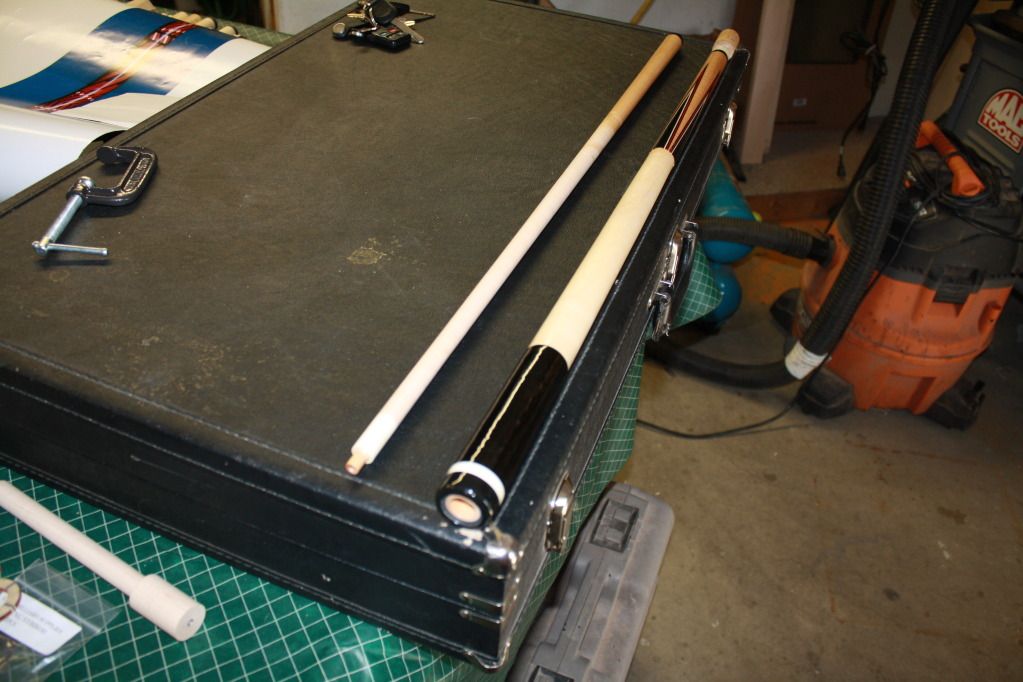

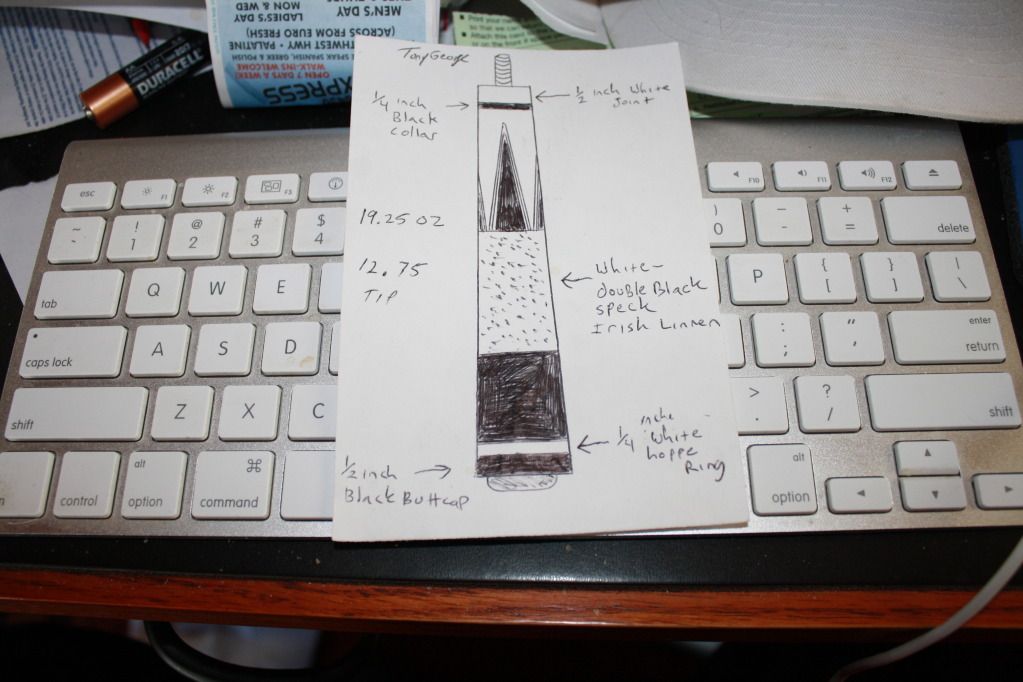

Tony's Cue Progress Pics

Tony,

Here is the curly front cored and glued to the dowel. The veneers will be here tomorrow and I will be making up the points.

Tony,

Here is the curly front cored and glued to the dowel. The veneers will be here tomorrow and I will be making up the points.

Last edited: