Hi,

I visited Darren Hill's shop yesterday to see his new 3rd generation shaft machine he has almost finished. Here are some pics of this trick pony.

This machine is awesome and is complete with a vernier controlled single DC Motor that performs all of the linear motion and and lathe functions. Quite impressive.

It has a completely adjustable tail stock and so you can handle everything from a full butt with a pin, oversized shafts, forearm, handle, butt sleeve, or straight dowel with ease. There is also a turret mount multi taper bar set up so you can quick change up to 4 tapers in about 30 seconds.

This baby is built on the 80/20 rails but the linear travel is on precision slide rail that travels effortless with very high accuracy.

The whole automation system is based on the speeds and feeds for the final pass concerning the gear ratio of the lead screw to the lathe function for the ultimate RMS finish. As the operator increases the travel speed the lathe speed increase for hogging and intermediate passes which is perfect because as you take a deeper cut on hogging for example, you need more torque and speed from the motor's power curve.

This unit is almost ready to ship to a very noteworthy cue maker that we all know and appreciate here on the form. Darrin has been working in his shop like a mad scientist putting in very long hours into the wee hours of the morning for over a month machining all of the components and assembling this beast.

Great Job Darrin!

Enjoy the pics,

Rick G

Darrin able to put a smile on his face as he is very close to completing the arduous task of making his third generation saw machine work to perfection

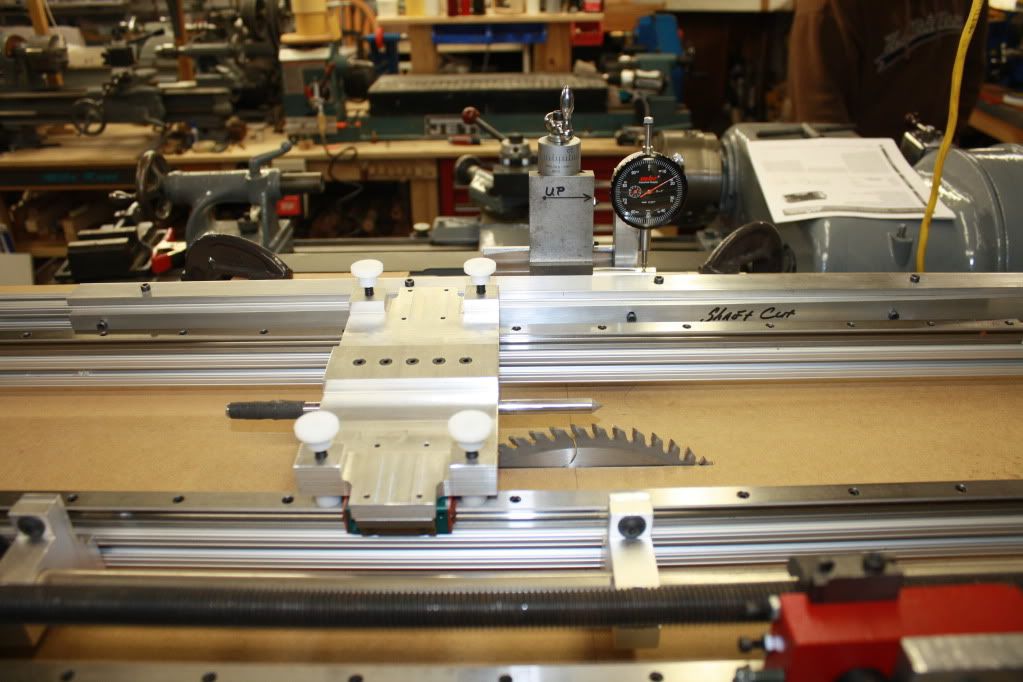

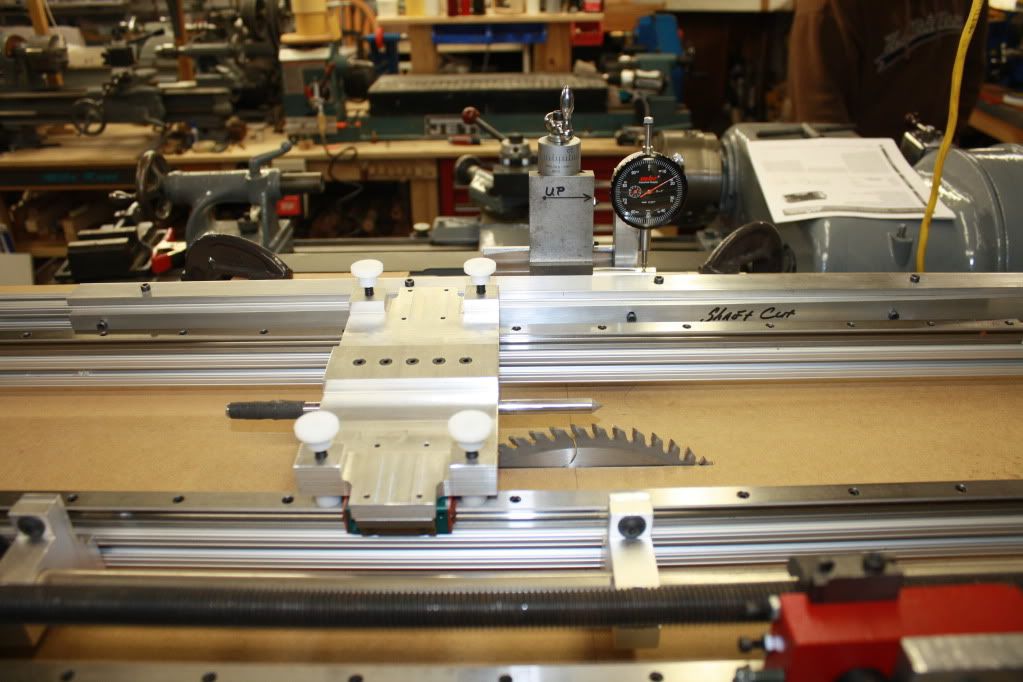

Adjustable tailstock mounted on pucks that slide on the linear tack system

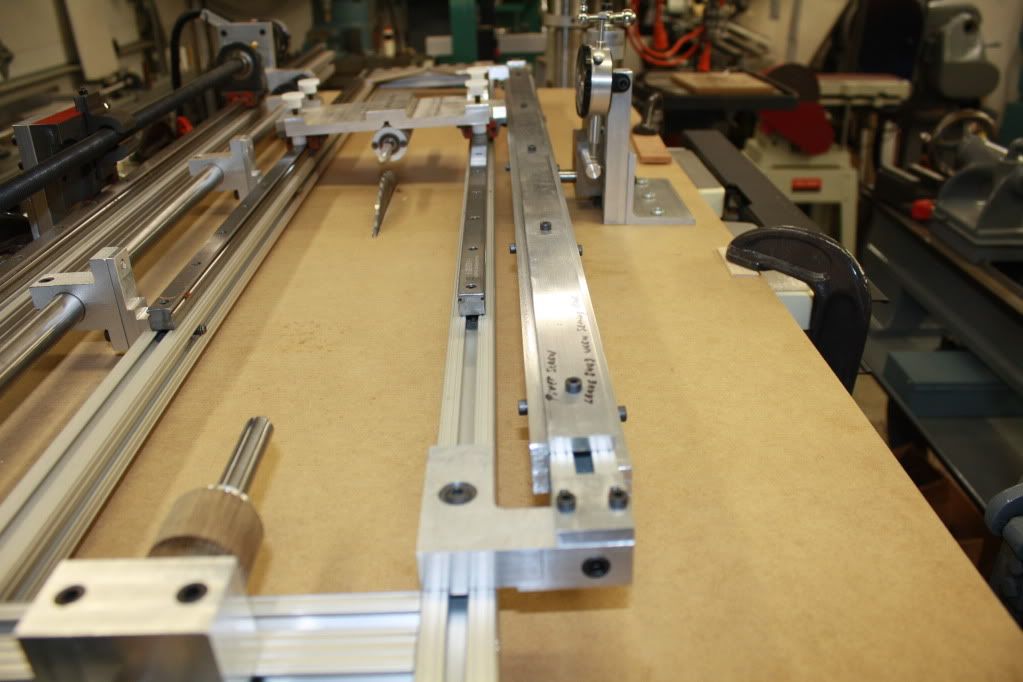

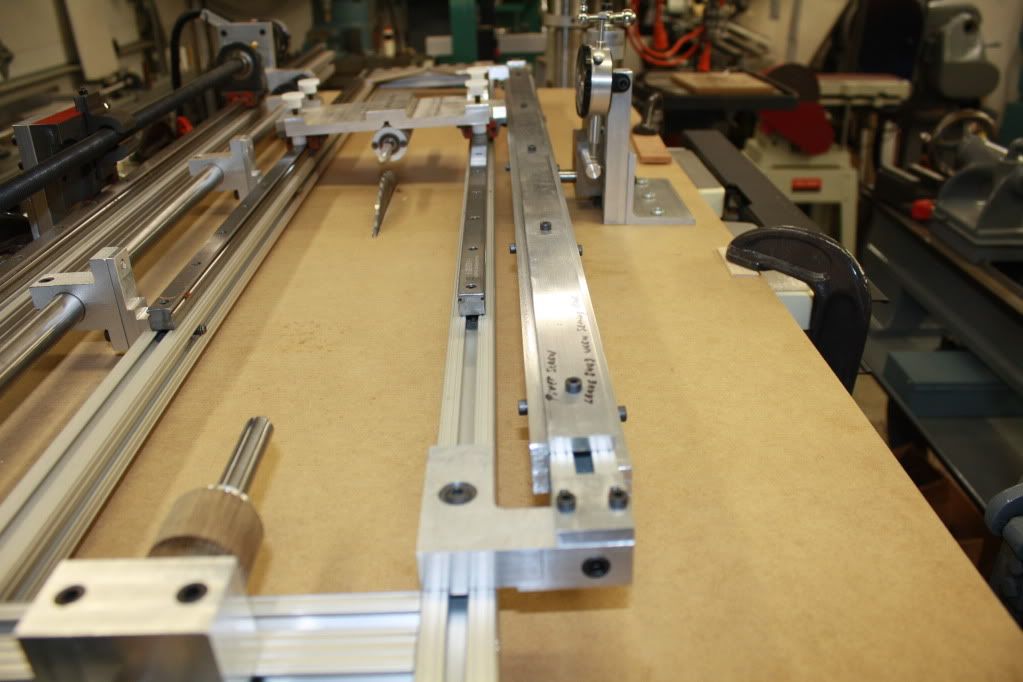

Quick change revolving taper bar set up

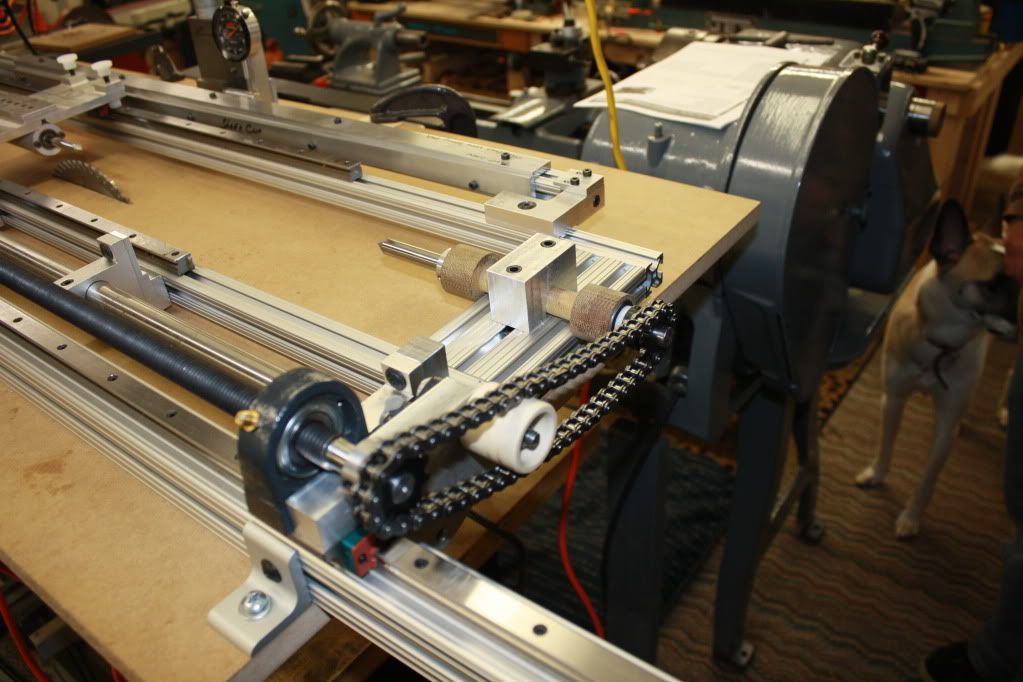

Smooth half nut set up for starting travel function

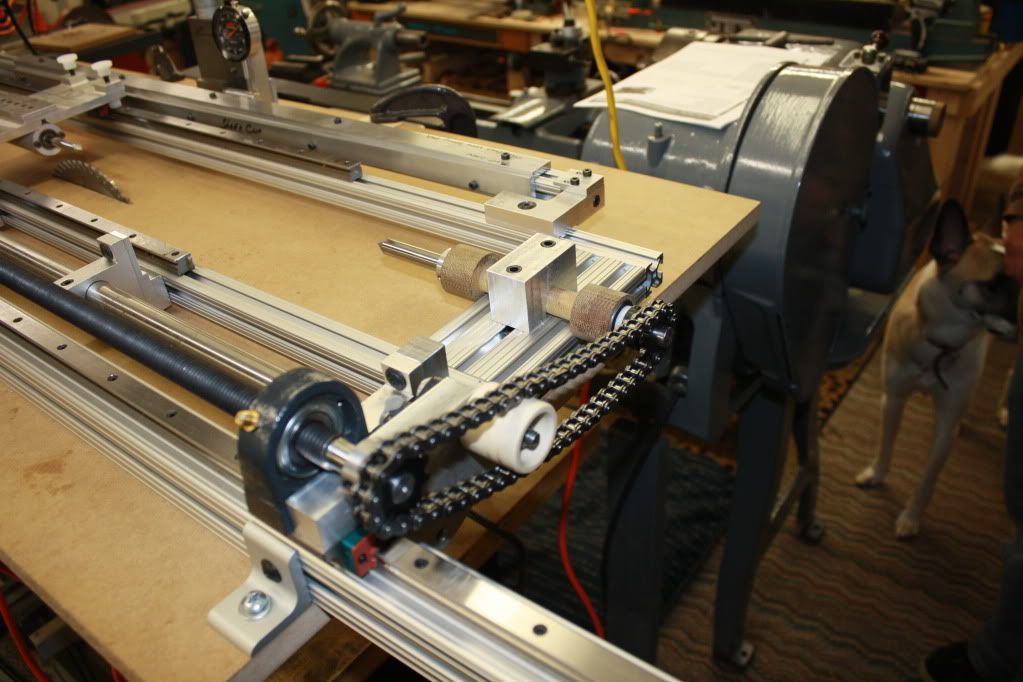

One more gear ratio adjustment needed to get the feeds and speed dialed in perfect. We test drove this baby today and timed the speeds with the laser tach and it needs to adjust up 6 extra teeth on the drive sprocket

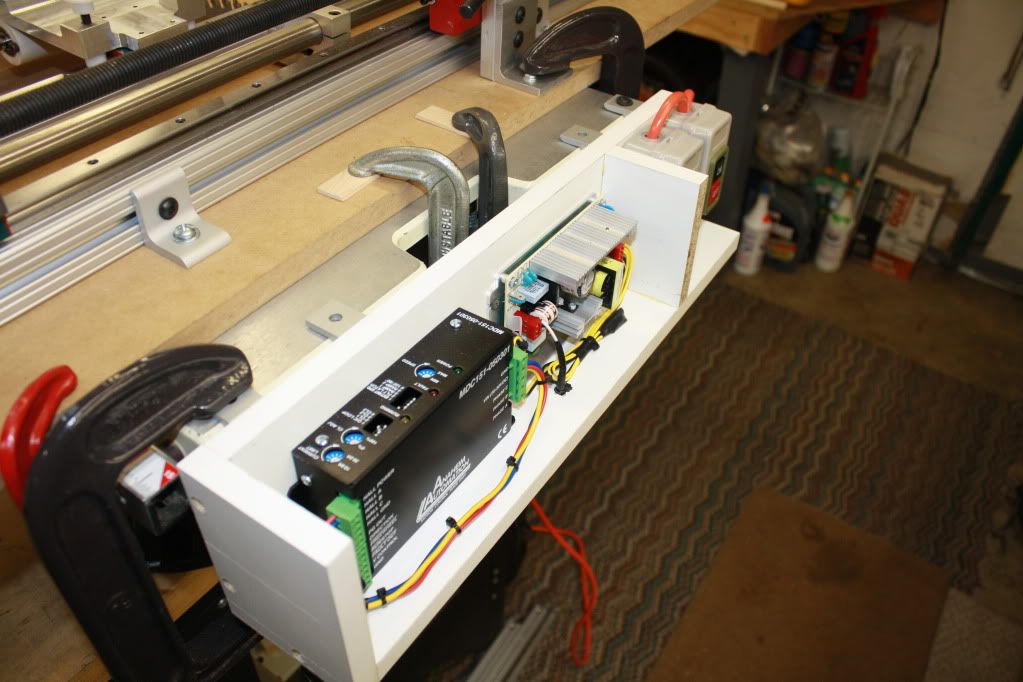

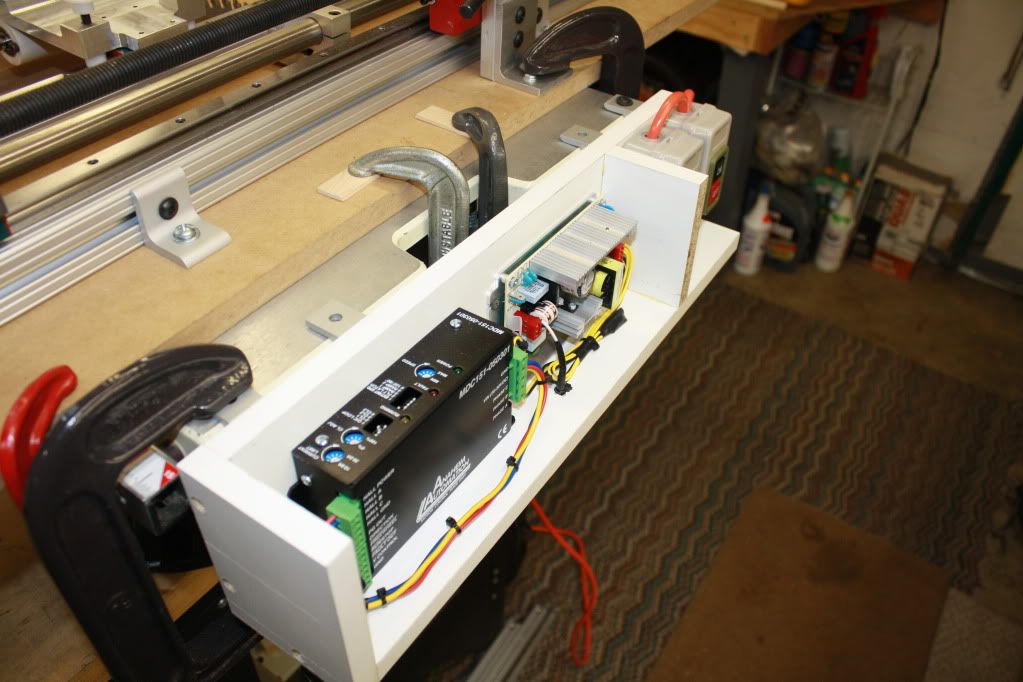

Power supply and DC controller ready for plexiglass enclosure plates.

E-Stop is completely adjustable. Note the linear travel rail mount in the foreground.

I visited Darren Hill's shop yesterday to see his new 3rd generation shaft machine he has almost finished. Here are some pics of this trick pony.

This machine is awesome and is complete with a vernier controlled single DC Motor that performs all of the linear motion and and lathe functions. Quite impressive.

It has a completely adjustable tail stock and so you can handle everything from a full butt with a pin, oversized shafts, forearm, handle, butt sleeve, or straight dowel with ease. There is also a turret mount multi taper bar set up so you can quick change up to 4 tapers in about 30 seconds.

This baby is built on the 80/20 rails but the linear travel is on precision slide rail that travels effortless with very high accuracy.

The whole automation system is based on the speeds and feeds for the final pass concerning the gear ratio of the lead screw to the lathe function for the ultimate RMS finish. As the operator increases the travel speed the lathe speed increase for hogging and intermediate passes which is perfect because as you take a deeper cut on hogging for example, you need more torque and speed from the motor's power curve.

This unit is almost ready to ship to a very noteworthy cue maker that we all know and appreciate here on the form. Darrin has been working in his shop like a mad scientist putting in very long hours into the wee hours of the morning for over a month machining all of the components and assembling this beast.

Great Job Darrin!

Enjoy the pics,

Rick G

Darrin able to put a smile on his face as he is very close to completing the arduous task of making his third generation saw machine work to perfection

Adjustable tailstock mounted on pucks that slide on the linear tack system

Quick change revolving taper bar set up

Smooth half nut set up for starting travel function

One more gear ratio adjustment needed to get the feeds and speed dialed in perfect. We test drove this baby today and timed the speeds with the laser tach and it needs to adjust up 6 extra teeth on the drive sprocket

Power supply and DC controller ready for plexiglass enclosure plates.

E-Stop is completely adjustable. Note the linear travel rail mount in the foreground.

Last edited: