You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

tenon threader?

- Thread starter chuckpilegis

- Start date

RBC

Deceased

You're off to a good start!

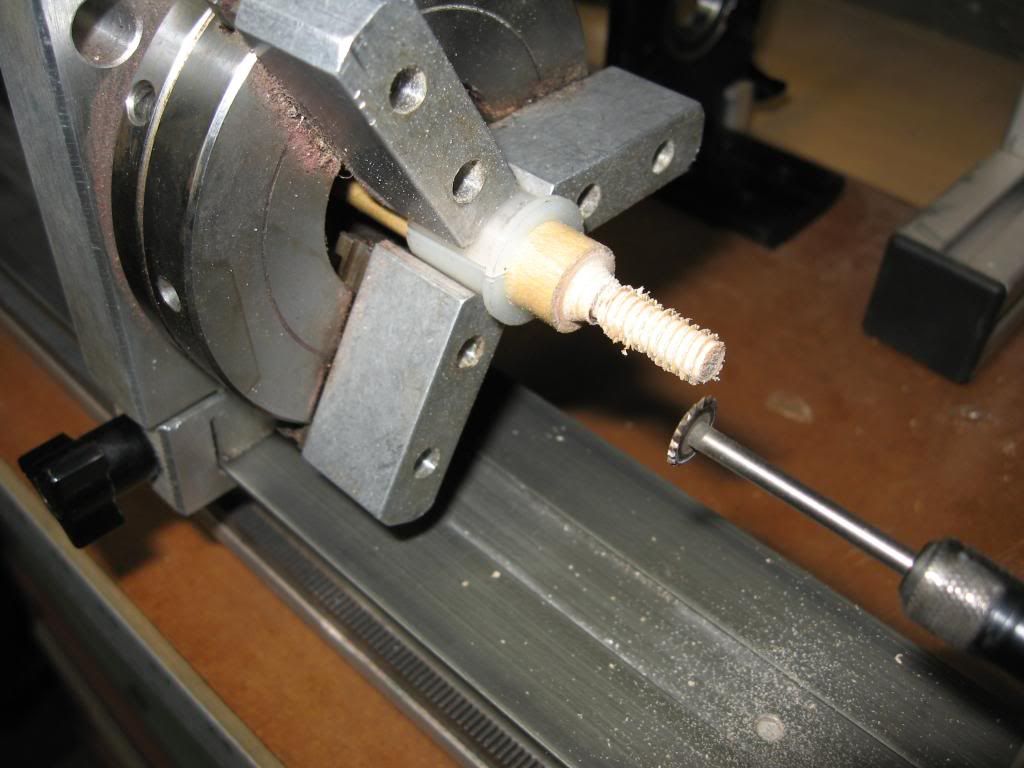

In the picture it looks like you cut the threads going in, and then maybe backed it out still cutting the threads? The reason I say this is because they appear to be double cut. If you cut going in, and then also cut going out, the backlash in your drive will shift your cutter and widen the threads. With live tooling, you should cut at a slow speed, and if you are going to make more than one pass, you need make all the passes in the same direction to account for the backlash.

Keep up the good work! Threading parts is the only way to go. We thread just about everything. Threads make the best glue clamps in the world.

Royce

threading

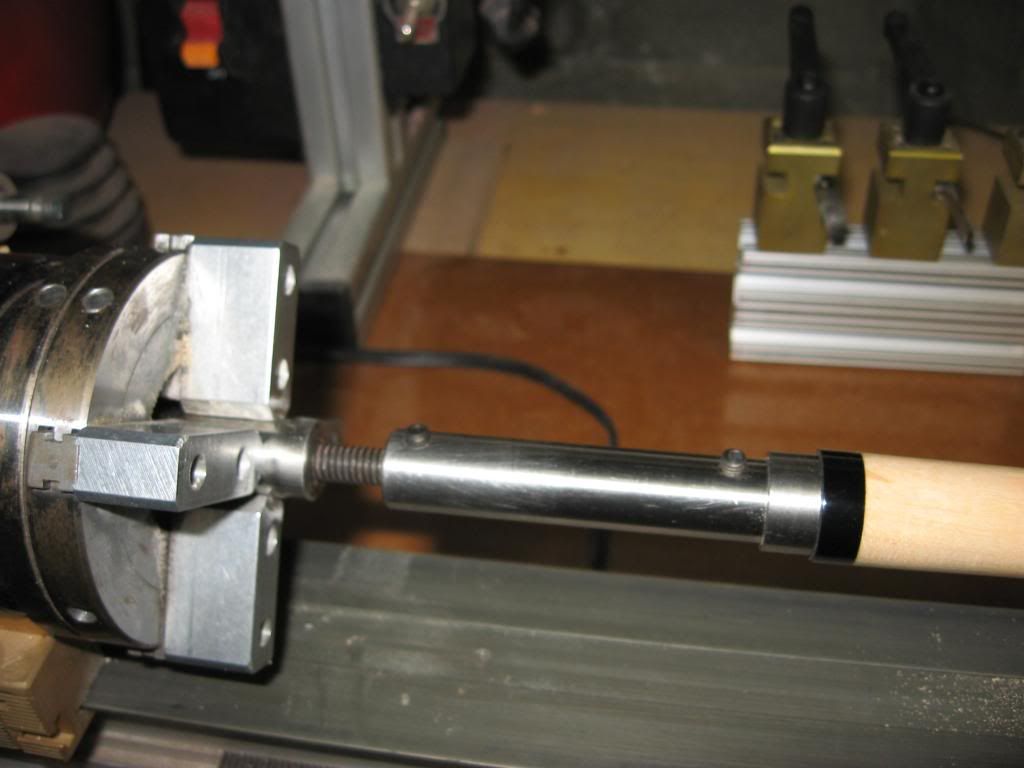

what are you using to feed the dremel the required thread pitch?

what are you using to feed the dremel the required thread pitch?

what are you using to feed the dremel the required thread pitch?

In his other post (post #4) he is showing what he is using to get the required thread pitch.

Great going!

The cutter is too long imo.

Cut it down to 1" ( exposed ) at the most .

You also do not need to make the threads on one pass.

Leave .010" for the final pass.

The cutter is too long imo.

Cut it down to 1" ( exposed ) at the most .

You also do not need to make the threads on one pass.

Leave .010" for the final pass.