I did a cue in Solarez to see how it is to work with. My shop was 64 deg when I finished the cue. the base coat/sealer is Max 1618 epoxy put on and cured for 3 days at 70 to 80 deg in my hot box. I sanded the epoxy flat to a .845 joint collar. I put on the Solarez while the cue was spinning slowly. I used the 4 oz squeeze bottle for an applicator. I spiraled the finish down the cue and then smoothed it out with a playing card until the sparkles were gone and it looked very flat. I added a little bit more and smoothed it again.

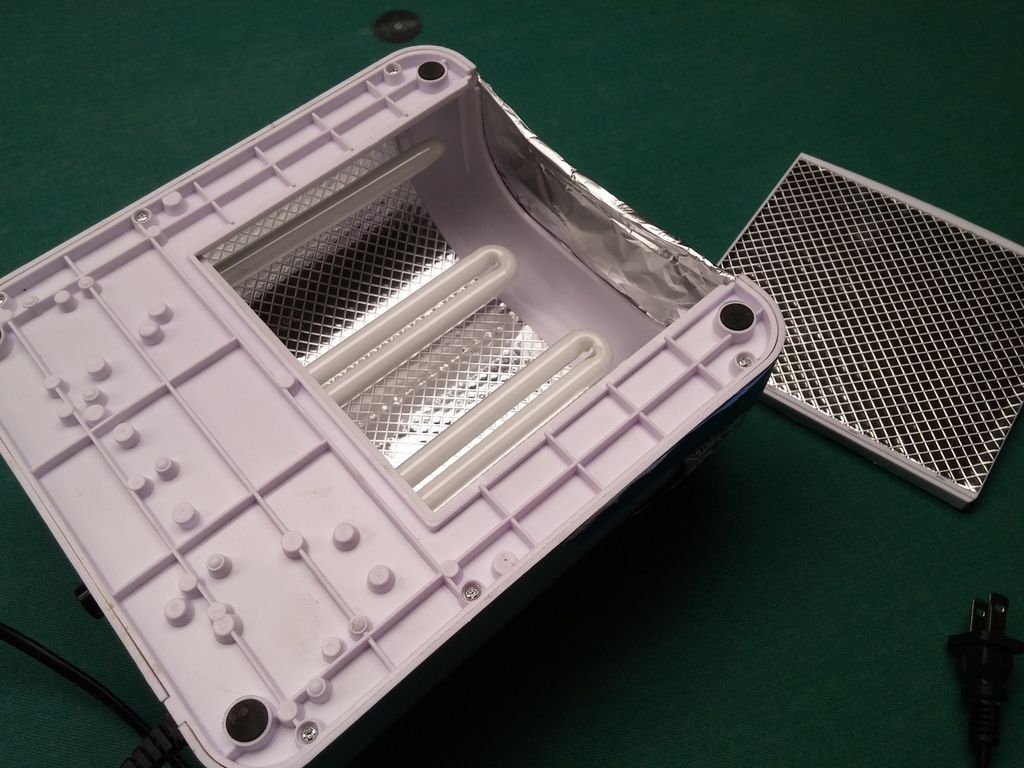

I gave it just a minute or 2 and then used the UV light to cure it. I use a 36 watt finger nail light from Ebay that costs $16. With the cue spinning slowly, I moved the light up and down the cue with the light a few inches away. I noticed the finish dulled a little as it began to cure. After about 10 minutes, it was hard as a rock.

The joint measured .859. I sanded the joint down to .850. I wet sanded length wise with 600, 1000, 1500, and 2000. Then I polished with 2 compounds while spinning and finished it off on the 12 inch buffing wheels.

It has an smell like automotive bondo that dissapears after it cures. I use a small exhaust fan and a respirator until I wet sand.

http://www.ebay.com/itm/36W-Profess...441875?hash=item35e6eb38d3:g:xccAAOSwNSxVBrSo

I slide off the bottom of the light and tape foil over the front to reflect all the UV light out the bottom........ seems to work well.

Kim

I gave it just a minute or 2 and then used the UV light to cure it. I use a 36 watt finger nail light from Ebay that costs $16. With the cue spinning slowly, I moved the light up and down the cue with the light a few inches away. I noticed the finish dulled a little as it began to cure. After about 10 minutes, it was hard as a rock.

The joint measured .859. I sanded the joint down to .850. I wet sanded length wise with 600, 1000, 1500, and 2000. Then I polished with 2 compounds while spinning and finished it off on the 12 inch buffing wheels.

It has an smell like automotive bondo that dissapears after it cures. I use a small exhaust fan and a respirator until I wet sand.

http://www.ebay.com/itm/36W-Profess...441875?hash=item35e6eb38d3:g:xccAAOSwNSxVBrSo

I slide off the bottom of the light and tape foil over the front to reflect all the UV light out the bottom........ seems to work well.

Kim