SSDiver2112

2b || !2b t^ ?

I have someone that wants me to fix their Dufferin one piece cue. Where the shaft is joined to the forearm it is loose and has a slight wiggle. Does anyone know how these are joined and is it possible to separate and fix. If not, should I just cut it apart and make a tenon to re-attach. Could there be a metal pin joining them or wood?

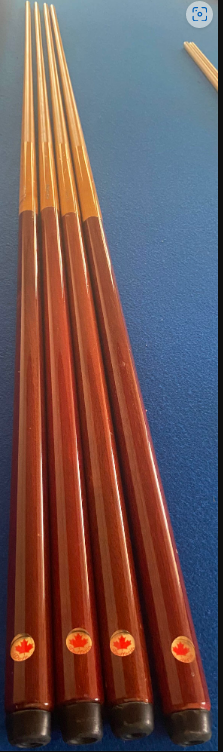

Not the actual cue, but same type.

Not the actual cue, but same type.