Point Groove indexing fixture review & recommendation!!!

Hi,

I just had a new point cutting fixture fabricated by a master machinist named Alan who lives in my area and I have known for over 10 years.

I gave Alan all of my requirements for the new jig and he delivered.

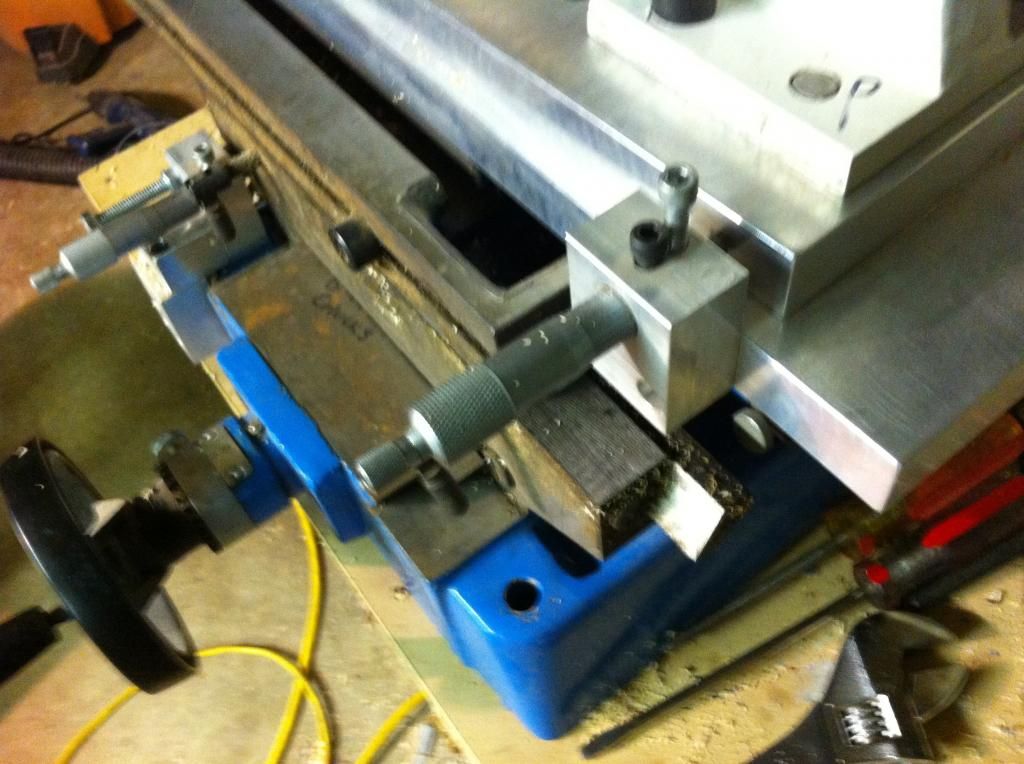

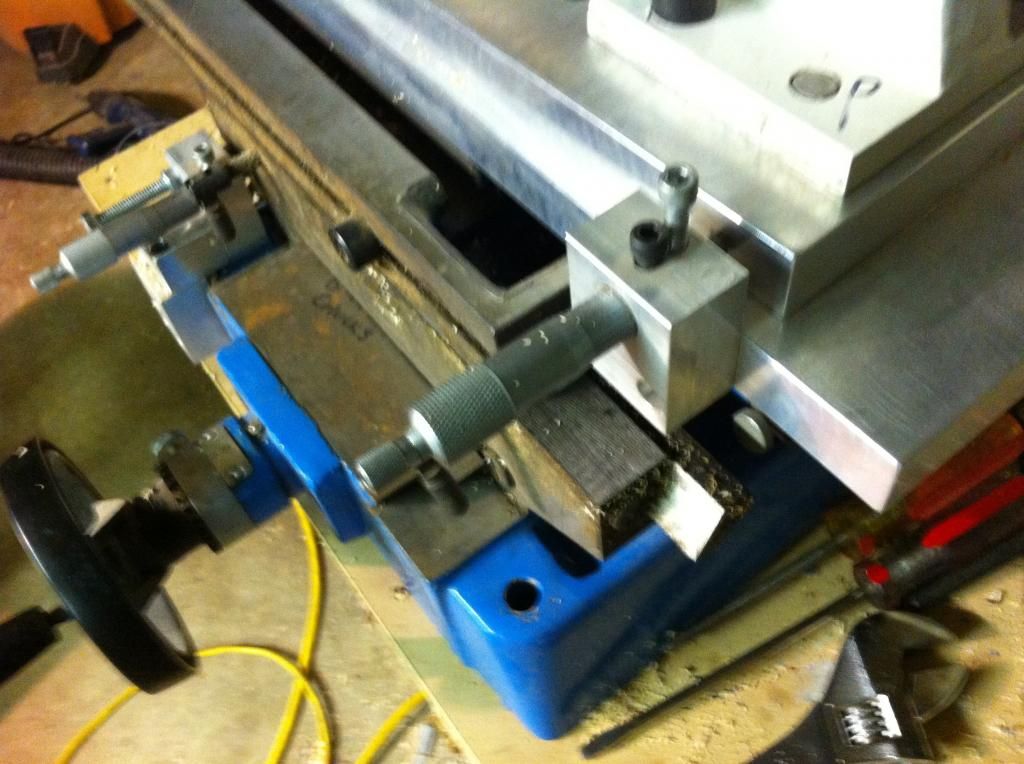

The accuracy and repeatability of this unit is scary. I had micrometers and mechanical adjustable stops installed on the Y- Axis and on the table angle. I have built 5 cues on the rig since Al installed it on my bench top mill using the T Slot system and I can go from 5 point to 4 point in different geometries in seconds. High low points to different lengths are also just a number on a chart. Plug and play. I can remove the table for other milling jobs and reinstall this unit in a few minutes and I am good to go right away.

The heavy duty alum billet stock to make the base and tilt table were all precision milled on both sides on Al's big CNC mill. He mounted the rotary indexer and tail stock with 1/2" ground dowel pins and the line up between centers is awesome.

The first thing I noticed when building my point cues with this baby was how perfect the points aligned not only on the ends but within the geometry of the intermediate veneer ends. Super workmanship.

If anyone wishes to get one of these units built by Al just give him a call. You will not be disappointed with his craftsmanship!

Al has also tweaked many other precision machine fixtures and tooling in my shop and he is very familiar with the cue making processes and understands intuitively how to fix problems and he can do design and engineering modifications to that end.

Anyone who wishes to contact Alan at info@wazprecisioncomponents.com

Rick

Hi,

I just had a new point cutting fixture fabricated by a master machinist named Alan who lives in my area and I have known for over 10 years.

I gave Alan all of my requirements for the new jig and he delivered.

The accuracy and repeatability of this unit is scary. I had micrometers and mechanical adjustable stops installed on the Y- Axis and on the table angle. I have built 5 cues on the rig since Al installed it on my bench top mill using the T Slot system and I can go from 5 point to 4 point in different geometries in seconds. High low points to different lengths are also just a number on a chart. Plug and play. I can remove the table for other milling jobs and reinstall this unit in a few minutes and I am good to go right away.

The heavy duty alum billet stock to make the base and tilt table were all precision milled on both sides on Al's big CNC mill. He mounted the rotary indexer and tail stock with 1/2" ground dowel pins and the line up between centers is awesome.

The first thing I noticed when building my point cues with this baby was how perfect the points aligned not only on the ends but within the geometry of the intermediate veneer ends. Super workmanship.

If anyone wishes to get one of these units built by Al just give him a call. You will not be disappointed with his craftsmanship!

Al has also tweaked many other precision machine fixtures and tooling in my shop and he is very familiar with the cue making processes and understands intuitively how to fix problems and he can do design and engineering modifications to that end.

Anyone who wishes to contact Alan at info@wazprecisioncomponents.com

Rick

Last edited: