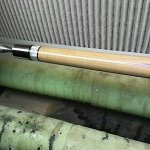

I've got a mid 70s Rich Q cue that has seen better days. The lacquer finish is pretty yellow and has been abraded away in places, enough so the joint is starting to corrode. I's like to refinish well enough to make a playable cue that looks more like it did when new.

The yellowed lacquer on the butt cap came off quite easily with just the side of a screwdriver and I just plan on doing a polish after reinstalling it. The bolt was a bit of a bear to get out even though it wasn't fully seated (the butt cap could rotate), should I plan on doing more than just cleaning the threads a bit with a wire wheel? Should I maybe use a bit of paste wax on the threads before it goes back in? What about gluing the butt cap, or is it supposed to just be seated by the bolt?

I'm thinking of masking the wrap, chucking up in the lathe and taking of the current finish with sand paper, then using finer and finer grit sandpaper until the surface is fully smooth, the re-shooting a clear coat. I might want to go with a finer polish on the stainless joint if it doesn't shine up to a brushed look with the sandpaper.

I don't have the original shaft for this cue, the one that came with it is off a plane jane sneaky pete. I do have a blank shaft though and judging by the cues offered in the 1976 brochure I should have a black band, then mother of pearl, then another black to match the other side of the stainless. Where is a good place to source that material? I assume you turn the shaft to an interference fit for the three bands then glue them. The thread on the butt side of the joint is 5/16-18, I assume I'll want an insert on the shaft side? At first glance they seem to be relatively easy to find.

I'm a bit of a newbie at this, as is probably obvious, and I'd appreciate any thoughts or pointers you can waft my way.

The yellowed lacquer on the butt cap came off quite easily with just the side of a screwdriver and I just plan on doing a polish after reinstalling it. The bolt was a bit of a bear to get out even though it wasn't fully seated (the butt cap could rotate), should I plan on doing more than just cleaning the threads a bit with a wire wheel? Should I maybe use a bit of paste wax on the threads before it goes back in? What about gluing the butt cap, or is it supposed to just be seated by the bolt?

I'm thinking of masking the wrap, chucking up in the lathe and taking of the current finish with sand paper, then using finer and finer grit sandpaper until the surface is fully smooth, the re-shooting a clear coat. I might want to go with a finer polish on the stainless joint if it doesn't shine up to a brushed look with the sandpaper.

I don't have the original shaft for this cue, the one that came with it is off a plane jane sneaky pete. I do have a blank shaft though and judging by the cues offered in the 1976 brochure I should have a black band, then mother of pearl, then another black to match the other side of the stainless. Where is a good place to source that material? I assume you turn the shaft to an interference fit for the three bands then glue them. The thread on the butt side of the joint is 5/16-18, I assume I'll want an insert on the shaft side? At first glance they seem to be relatively easy to find.

I'm a bit of a newbie at this, as is probably obvious, and I'd appreciate any thoughts or pointers you can waft my way.