Good question Alan - and rest assured, no one in history has ever been more confused

than I was trying to imagine how to make a forearm with points.

As noted before, I don't actually use Trig, tho it could be done that way. Bit of an inside joke

But no, the offset doesn't have any effect, nor does any machining technique used to

to create the taper - of which there are several options - don't get me started on Snooker cues

After re-reading, the offset does have an effect in that it determines the angle of the

taper.

But you don't really need to use any angles to calc for point length - you don't

even have to know what the angles are.

Dale(who prefers the rise-and-run method)

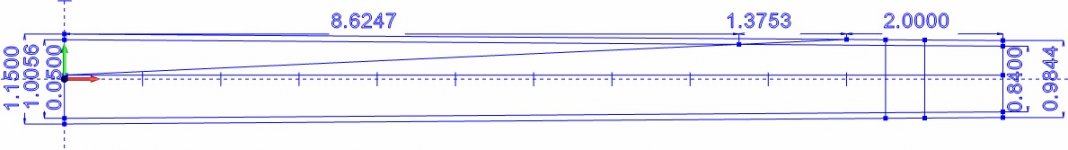

You don't have to know what the actual angles are, but you need data describing the taper of the bottom of the Vee groove. Rise over run is a slope, which is the results of an angle.

Take two forearms that are exactly .925 diameter at the end of the points and the point length is exactly 10 inches for both. Take a cut on both, say .050" diameter removal. If either the taper of the cut is different on the two, or the taper of the bottom of the Vee groove when it was machined is different on the two forearms, the points will now be different lengths (saving both tapers are different and you got lucky because the differences canceled each other out). How much different will they be? Almost not measureable because the two tapers don't vary much between cues.