I do not know anything about the particular chuck you have, but I am seeing quite a few chucks these days are not very good right from the get go. They will zero out at a particular size, and every size either above or below, they can run out as much as 0.006 inches, or 0.15mm.

This has never been a problem until the poorly made chinese chucks came to the market place. Sounds like they don't "Repeat".

We are all watching our budget but some things you just can't cut corners on. A chuck is one of those things.

On a budget? look for chucks made in Poland, Japan, Germany, France, England, and the U.S.

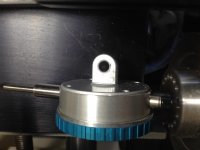

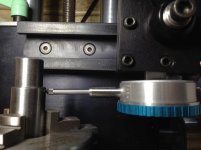

You want to change your life forever? buy an "adjustable" chuck. Or convert a quality chuck into an adjustable chuck.

Makers names to look for are, Buck, Forkardt, Cushman, Pratt Burnerd, Bison, and Skinner.

Buck and Forkardt merged if I remember right.

Other makers as well. So long as they were made in a country that produces well made tooling.

And so long as the chuck appears to be well cared for and not abused.

First thing take it apart, clean it, inspect it, oil it, and reassemble it.

I also recommend that you look for a metric DTI, the divisions are about the same spacing, but each division is about 4/10000 of an inch instead of 0.001 inch. So a 0.003 inch reading will be about 0.07 + 1/2 division. Just makes life a lot easier as you get older eyes. The 0.005 marked indicators seem to have too many markings all crammed in and I find awkward to read compared to the metric indicators. I do have inch stuff to use for travel on either X or Z for the Taig type or the imperial lathe I have. But I now always use the Metric DTI's for indicating runout.

Neil

No need to go metric.

It's all is what you choose. Some metric test indicators have small dials and narrow divisions too.

Consider getting an Interapid 312B-1 in .0005"

(Or the Brown& Sharpe equivalent)

(Interapid, Brown & Sharpe, and Tesa have merged)

Nice big face, wide divisions, Jeweled, self reversing, Swiss made, etc.

The truth is working, with and using, quality instruments and work holding devices is a pleasure. You enjoy using them.

Compare that to the lost time and frustration of dealing with poorly made products.

It makes buying right the first time a bargain all round.