so the work of total cloth recovering I was talking about in this thread started.

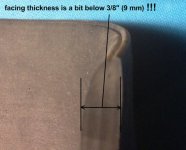

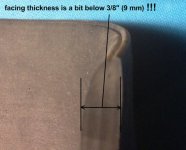

This is how the pockets were done before. These might be two facings stacked together or maybe it's the very same double-layer rubber they are going to use now. It is as thick as 9 mm...

I know extending the rail is the way to go, but it turned out that's out of question this time (no time and no money for such work). So the question my friend asked, whether it is correct the mechs are going to make the facing of that single piece of rubber (to keep the opening size at least).

I suggested they try doing it this way. If wooden subrail extension can not be done now, replace it with rubber "extension" and mount a facing upon that one, so that the facing is of proper thickness.

Later my friend send me a message this way the balls rattle more. I didn't have a chance to talk to him, so I don't know which way they picked but I guess it would be one single thick facing.

Please comment on any of the pockets pictures. I have a strong feeling they are all wrong to some extent, but which would you call the better of others?

This is how the pockets were done before. These might be two facings stacked together or maybe it's the very same double-layer rubber they are going to use now. It is as thick as 9 mm...

I know extending the rail is the way to go, but it turned out that's out of question this time (no time and no money for such work). So the question my friend asked, whether it is correct the mechs are going to make the facing of that single piece of rubber (to keep the opening size at least).

I suggested they try doing it this way. If wooden subrail extension can not be done now, replace it with rubber "extension" and mount a facing upon that one, so that the facing is of proper thickness.

Later my friend send me a message this way the balls rattle more. I didn't have a chance to talk to him, so I don't know which way they picked but I guess it would be one single thick facing.

Please comment on any of the pockets pictures. I have a strong feeling they are all wrong to some extent, but which would you call the better of others?

Last edited: