Well my cue is down at mcdermott getting some work done. What are some general dimensions for the butt end of the cue. Length, diameters at joint and butt. Distance from joint to front of grip. Length of the grip. And so forth. Im in a 3d modeling class and for fun I want to make a cue on there, and actually make it out of aluminum when I have it fully designed. Im just making the butt as im just going to use a wood shaft. Any help would be greatly appreciated. Oh yeah this isnt going to be a normal playing cue, just something for fun to try. thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cue dimensions?

- Thread starter jprochnow

- Start date

Well my cue is down at mcdermott getting some work done. What are some general dimensions for the butt end of the cue. Length, diameters at joint and butt. Distance from joint to front of grip. Length of the grip. And so forth. Im in a 3d modeling class and for fun I want to make a cue on there, and actually make it out of aluminum when I have it fully designed. Im just making the butt as im just going to use a wood shaft. Any help would be greatly appreciated. Oh yeah this isnt going to be a normal playing cue, just something for fun to try. thanks

Try .840 joint and 1.250 at the bottom ( one angle for simplicity ).

12" long forearm, 12" long handle and 5" sleeve.

Try .840 joint and 1.250 at the bottom ( one angle for simplicity ).

12" long forearm, 12" long handle and 5" sleeve.

Ditto. Good roundabout dimensions.

Try .840 joint and 1.250 at the bottom ( one angle for simplicity ).

12" long forearm, 12" long handle and 5" sleeve.

Aw, c'mon. No compound taper? Where is the challenge that? :grin:

Scott <<== just broke a rule..... I think

compound taper? Is that where the handle is the same diameter the whole length? This is going to be interesting, making it out of aluminum and hopefully remove enough material to weigh the same as a normal cue. 19-20oz. How thick is the leather for a wrap? I then can calculate the diameter of the handle without the wrap installed.

Most leather I have is between .020"-.030"

Will be a challenge making an aluminum cue that weighs only 19oz & still retain it's structural strength. Cut too much out & it'll be like a soda can.

Yeah I know that. thats why its going to be a fun thing to design. I'm going to mill it out of 3 pieces of aluminum.

Should be interesting...

If metal, I might suggest Magnesium. 'butt' it like bicycle tubing- thicker at the ends and thinner in the middle(bore the ID to create your butts). The forearm, handle, and butt pieces can be separate, but they should all be butted like that I think to save weight. Your program can estimate weight and center of gravity easily.

Try to get the CG close to center of the butt I think; or add the known moment of the wood shaft to your model and get the entire CG close to 18-19 inches from the butt end (everyone wants it in a different place, so put it where you think it should be).

If you can't get the weight down to ~15 ounces of the butt alone, maybe try adding in carbon fiber tubing for the butt sleeve and/or handle piece... This can also be butted if needed. White Delrin is the traditional butt cap material, and it is reasonably light. Using this to replace a piece of aluminum (or magnesium) in the butt should save an ounce or two.

Sounds like a fun project! I'd like to see pictures when you finish it.:thumbup:

If metal, I might suggest Magnesium. 'butt' it like bicycle tubing- thicker at the ends and thinner in the middle(bore the ID to create your butts). The forearm, handle, and butt pieces can be separate, but they should all be butted like that I think to save weight. Your program can estimate weight and center of gravity easily.

Try to get the CG close to center of the butt I think; or add the known moment of the wood shaft to your model and get the entire CG close to 18-19 inches from the butt end (everyone wants it in a different place, so put it where you think it should be).

If you can't get the weight down to ~15 ounces of the butt alone, maybe try adding in carbon fiber tubing for the butt sleeve and/or handle piece... This can also be butted if needed. White Delrin is the traditional butt cap material, and it is reasonably light. Using this to replace a piece of aluminum (or magnesium) in the butt should save an ounce or two.

Sounds like a fun project! I'd like to see pictures when you finish it.:thumbup:

Aw, c'mon. No compound taper? Where is the challenge that? :grin:

Scott <<== just broke a rule..... I think

Shush now brother......... lmao

Aw, c'mon. No compound taper? Where is the challenge that? :grin:

Scott <<== just broke a rule..... I think

No, those roll funny on the table.

Besides, drawing arcs on cad is so much more complicated than drawing lines. :thumbup:

.420" vertical line, 29" horizontal line and .625" vertical line, connect the dots, revolve. Voila!

JP, are you going to draw the butt as a 3-piece assembly or one long cone?

Last edited:

Well my cue is down at mcdermott getting some work done. What are some general dimensions for the butt end of the cue. Length, diameters at joint and butt. Distance from joint to front of grip. Length of the grip. And so forth. Im in a 3d modeling class and for fun I want to make a cue on there, and actually make it out of aluminum when I have it fully designed. Im just making the butt as im just going to use a wood shaft. Any help would be greatly appreciated. Oh yeah this isnt going to be a normal playing cue, just something for fun to try. thanks

I can understand the interest. I have a full size stainless steel butt (drilled for weight reduction but still weighs about 20 lbs) and a titanium shaft! It's kind of silly, but a definate conversation piece at a pool room! If I get a chance I'll try to shoot a couple of pics.

I'll be making it a 3 pc butt with a press in bumper. Im using assembly mode in UGS nx 6. Does anyone use this software? Im trying to figure out how to draw a sketch around a cylinder. But having no luck.

K.

I use Inventor.

After extruding one piece ( say the forearm ).

I switch to 2-d drawing mode. Draw another circle at the face.

Then extrude that circle again.

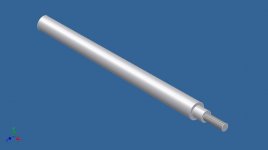

Attachments

K.

I use Inventor.

After extruding one piece ( say the forearm ).

I switch to 2-d drawing mode. Draw another circle at the face.

Then extrude that circle again.

Nice pic, I havent had any time the past day to get started on designing it. But I will for sure on monday. Whats a good thread size for the joint?

Ok im trying to make a 3/8-10 joint with my software but it needs some specs. What is the major diameter, minor diameter, pitch, and angle of that joint bolt? I want to make the forarm with an intergrated bolt that is machined in. That way I can hollow out the forarm