Diary of an Antique Brunswick Redux

This is my update for the Diary of an Antique Brunswick, er ah, probably Oliver Briggs. I was never happy with the cushion response when I did all of the work a year or so ago. So, I bought some Brunswick Super Speed Cushions and decided to replace the Championship Tour Edition Cushions. After Jay from A-1 looked at my table, (Thank You Jay!), I figured while doing the cushion replacement I could make some more improvements while I had this apart. So, here we go again!

I pulled the first rail apart and made some measurements and mock ups. This when I found my concern. The sub-rail was not at the 20 degree angle it should have been and was at 23 degrees. I spoke with one of the members here in the mechanics section and he said I would be just fine at the 23 degrees I had. I just needed to get the cushion lowered so that I could mount the cushion centered on the sub-rail and still be at 1 7/16. I do not think that the 1/16” or so that the cushion mounted low on the sub-rail really effected the cushion response. So, if I am not changing the sub-rail angle and lowering the rails isn’t going to net anything then I am really depending upon the Superspeed cushions to do the trick.

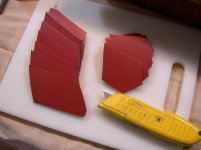

The next part of this round of improvements is to do a better job with the angles of my pocket openings and if I am doing this I am taking the pockets down to 4.25”. When I did the sub-rail extensions before I just glued and nailed them on and thought I was pretty close on all the angles which I was, except, for the downdraft angle. I just did not use any sort of protracter to find and measure the angles. The one I have is from Home Depot and was only ten bucks. Really the pockets did not play bad at all but the facings I used were very hard. I suspect this really kills the speed and deflection of the ball when it hits the pocket facing making the balls easier to pocket.

I made measurements and although I did not have accurate points to measure from my rails had variations in length. One of my end rails was 1/4” shorter than the other for sure. This would account for why I had slightly larger pockets on one end of the table. Further inspection to make sure the sub-rails were not loose I could tell someone had replaced the sub-rails. These sub-rails would have to have been sawn after installation. The other discovery I made was that one of my side pockets was not centered on the table by 3/8” and one of the corner pockets was off by a bit as well.