"Mr. Billiard," the gentleman who owned Long's Billiards in VA years ago (I am told he is retired and the son owns Long's now), told me at a trade show that he converted T-rail tables to the better playing modern style rail bolt system with new bolts coming from below rather than the side of the rails. I asked him why not just have bolts from the side AND the bottom, and he said yes that works also but some folks don't like so many bolts in case of recovering the table. I am wondering if anyone has seen a table that Long's has converted this way. I am told that slate drills through like butter, so it would not be a big deal, but it seems like inserts would be put into the slate for the bolts to enter. Any suggestions? I went by Long's in person recently to see about having this done by them... I wanted to see an example, but the new owner never called me back. I want to make my Kling 3-Cushion table play perrrrfect.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T-rail bolt system conversion per Mr. Long

- Thread starter hunger strike

- Start date

You'd need substantial inserts into the underside of the rails to accept machine bolts coming through the slate. No inserts in the slate

One question would be> is this new mating surface [ slate to bottom of the rail] large enough on a T rail?

The modern rails, like on the GC, are quite a bit wider.

Interesting idea, but I defer .... a little knowledge is a dangerous thing.

I believe Mark Gregory mentioned this recently here.

One question would be> is this new mating surface [ slate to bottom of the rail] large enough on a T rail?

The modern rails, like on the GC, are quite a bit wider.

Interesting idea, but I defer .... a little knowledge is a dangerous thing.

I believe Mark Gregory mentioned this recently here.

Last edited:

Does Mark Gregory want to comment?

I hope he does, or maybe he can send a link. When I asked Mr. Long, those were my thoughts exactly. If you kept the original T-rail bolts in place, you wouldn't need such large bolts from below and inserts above, just something to add stability in another direction. For those of you who have never owned an antique Brunswick, the bolts have to be tightened up often and since there are rail blinds over that that sometimes aren't so easy to put back on, that is a real pain.

My friend Mel Cheek, when he lived in Edmond, OK, restored his own Arcade billiard table. He told me that Ceulemans himself visited his home and played on that Arcade and that it played just fine, no complaints. So I know an old Brunswick can be set up to play great, I just want to know how. I have played a session of 3C where I averaged about .80, and for me that is absolutely raining billiards. Once you've had a taste of playing really good 3C, you wanna get even better.

I hope he does, or maybe he can send a link. When I asked Mr. Long, those were my thoughts exactly. If you kept the original T-rail bolts in place, you wouldn't need such large bolts from below and inserts above, just something to add stability in another direction. For those of you who have never owned an antique Brunswick, the bolts have to be tightened up often and since there are rail blinds over that that sometimes aren't so easy to put back on, that is a real pain.

My friend Mel Cheek, when he lived in Edmond, OK, restored his own Arcade billiard table. He told me that Ceulemans himself visited his home and played on that Arcade and that it played just fine, no complaints. So I know an old Brunswick can be set up to play great, I just want to know how. I have played a session of 3C where I averaged about .80, and for me that is absolutely raining billiards. Once you've had a taste of playing really good 3C, you wanna get even better.

Sounds like a good idea to me, it may or may not work with most antique tables because the slate sits almost flush with the frame/ body or edge of the table with no overhang to install the bolts from the bottom up.

perfectpocketz

Banned

Hey....I have just completed the Kling pocket table that I put pics on the main forum....I did complete new sub-rails with brunswick super speed cushions...and GC spec's for the the sub-rails.....how ever the guy didn't want the pockets tighted.....the table played like a GC....and it was a lot of work.....as far as rail bolts on antique t-rail tables from the bottom of the slates.....I've never heard of that.....as Mechanic/player stated...antiques that I've seen all have the slates flush with the frame.....and if you look at the under side of the rail where the sub-rail meets the t-rail some have cloth reliefs...leaving only about 3/4 of and inch for footprint....rails that bolt from the bottom...have over hanging slates from the frame....the sub-rails on antique tables were not designed to play the way players demand today....but you can change the sub-rail spec's and make the tables play a lot better......the 55 cushions also help out for the play....as far as I know....I don't believe bolts can be put in the bottom of and antique t-rail table.....as far as your billiard table....klebar cushions and new sub-rails will without doubt make a mojor change in playability.....if you look under a rail for a standard pool table....all the rail bolts go through the footprint.....not the sub-rail....so how does someone bolt and antique t-rail table from under the table???

Last edited:

"Mr. Billiard," the gentleman who owned Long's Billiards in VA years ago (I am told he is retired and the son owns Long's now), told me at a trade show that he converted T-rail tables to the better playing modern style rail bolt system with new bolts coming from below rather than the side of the rails. I asked him why not just have bolts from the side AND the bottom, and he said yes that works also but some folks don't like so many bolts in case of recovering the table. I am wondering if anyone has seen a table that Long's has converted this way. I am told that slate drills through like butter, so it would not be a big deal, but it seems like inserts would be put into the slate for the bolts to enter. Any suggestions? I went by Long's in person recently to see about having this done by them... I wanted to see an example, but the new owner never called me back. I want to make my Kling 3-Cushion table play perrrrfect.

Can't be done on T-railed tables because the slate is not wide enough to run the bolts upward through the slate into the bottom of the rails....because where the rail bolt would have to go through the slate...there is no slate, you'd have to be running the rail bolt up through the rail under the sights. A T-rail slate for a 50"x100" 9ft playing surface has a slate that is 54"x104" whereas a modern era slate for a 9ft is 57"x107"...that 1 1/2" missing all the way around the outside edge of the slate that is not there on the T-rail slate is what is needed in order to bolt the rails down from under the bottom of the slate. As well as what was already mentioned...there is almost no overhang of the slate past the body of the table...meaning maybe only 1/4" overhang....certainly no place to run a bolt up through the slate from the bottom side.

I think someone was blowing some smoke somewhere when you were told that, or smoking something at the least

....I don't believe bolts can be put in the bottom of and antique t-rail table.....as far as your billiard table....klebar cushions and new sub-rails will without doubt make a mojor change in playability.....if you look under a rail for a standard pool table....all the rail bolts go through the footprint.....not the sub-rail....so how does someone bolt and antique t-rail table from under the table???

in your kling thread this guy posted...this....

"I've had two Anniversarys oversized 8-footers, one Arcade and now have a Kling. See links below.

The Kling was a damaged 10' Snooker table we converted to a 9' drop-pocket 6-legged Kling. We also added up-bolts to tighten the rails and avoid the classic Brunswick stripped edge-bolt problem although we still insert the bolts and tighten them with the Brunswick bolt-head wrench

I have also acquired a 10' Hudson Carom. I'm not sure if I am going to leave it a Carom table, make it a 10' pocket or a 9' pocket table. Probably leave it a Carom table.

http://www.carlopool.com/Kling.htm

http://www.carlopool.com/KlingProject.htm"

original thread here

http://forums.azbilliards.com/showthread.php?t=263620&highlight=kling&page=2

so if you take a 10 foot slate and make a 9 footer out of it then you can probably leave the overhand to insert the up bolts...

Can't be done, because the Kling 9ft rails still won't bolt up from the bottom side...period. As it is to turn a 10' into a 9ft, the frame and slate would have to be cut down in size, but the 9ft Kling rails still would have to be bolted in from the side, not the bottom.

Glen

Glen

Can't be done, because the Kling 9ft rails still won't bolt up from the bottom side...period. As it is to turn a 10' into a 9ft, the frame and slate would have to be cut down in size, but the 9ft Kling rails still would have to be bolted in from the side, not the bottom.

Glen

it looks like this kling was built from the ground up ...so they probably re-designed the rails...look at the pictures..

http://www.carlopool.com/KlingProject.htm

http://www.carlopool.com/images/Tables/Kling/RailRework1.jpg

I think the up bolts they are talking about may go right into the subrail but it's hard to tell

a man by the name of Art Bell apparently did the wood work. I will ask this carlopool to comment on this thread so he can explain how he did it.?

Great info...

Maybe Mr. Long already had Alzheimer's by then, but someone else at Long's subsequently told me that they do that work and their estimate was in the thousands. I am pals w Cuephoric, and I am sure he could have told me all this same great info. I guess what I was looking for is anyone who had seen Long's work...seems like any mechanic would have recognized this if they'd seen it. My table mechanic friends, including Shane, and Joplin's Ted Pierson, were not likely to have seen this VA-based work, so I thought I would ask on here. I am starting to wonder if the old guy just ran screws through the slate into the subrail. Well, he was a nice old gentleman anyway. I guess I'll have Cuephoric do the subrails as you suggest. My other pal Randy Burke at Orner in Indy had never seen that conversion either. If I had worked for Brunswick back then, I would have suggested using the same dowels that pin the slate to stabilize the rails vertically....wonder if that would have worked....

Maybe Mr. Long already had Alzheimer's by then, but someone else at Long's subsequently told me that they do that work and their estimate was in the thousands. I am pals w Cuephoric, and I am sure he could have told me all this same great info. I guess what I was looking for is anyone who had seen Long's work...seems like any mechanic would have recognized this if they'd seen it. My table mechanic friends, including Shane, and Joplin's Ted Pierson, were not likely to have seen this VA-based work, so I thought I would ask on here. I am starting to wonder if the old guy just ran screws through the slate into the subrail. Well, he was a nice old gentleman anyway. I guess I'll have Cuephoric do the subrails as you suggest. My other pal Randy Burke at Orner in Indy had never seen that conversion either. If I had worked for Brunswick back then, I would have suggested using the same dowels that pin the slate to stabilize the rails vertically....wonder if that would have worked....

perfectpocketz

Banned

in your kling thread this guy posted...this....

"I've had two Anniversarys oversized 8-footers, one Arcade and now have a Kling. See links below.

The Kling was a damaged 10' Snooker table we converted to a 9' drop-pocket 6-legged Kling. We also added up-bolts to tighten the rails and avoid the classic Brunswick stripped edge-bolt problem although we still insert the bolts and tighten them with the Brunswick bolt-head wrench

I have also acquired a 10' Hudson Carom. I'm not sure if I am going to leave it a Carom table, make it a 10' pocket or a 9' pocket table. Probably leave it a Carom table.

http://www.carlopool.com/Kling.htm

http://www.carlopool.com/KlingProject.htm"

original thread here

http://forums.azbilliards.com/showthread.php?t=263620&highlight=kling&page=2

so if you take a 10 foot slate and make a 9 footer out of it then you can probably leave the overhand to insert the up bolts...

Sounds to me like they cut the frame smaller.....cut the slates wider and longer and over hung the slates and added some up bolts.....I really don't know without seeing the frame and slates.....I'm not and antique specialist.....I do know how to calibrate just about any rail to play better.....The guy's do fantastic wood work on the rails and tables....we all see that.....hell of a wood working shop they have......I don't do that kind of work nor do I have the tooling those guy's have......Looks to me like they do awesome refinishing and restoration on antique tables.....Like I said before....I've never heard of that being done....don't mean someone can't modify any table....to what they want it to be.....I'm going to stick to what I know for sure.....and fix rails to play the way players want......I know one thing for sure.....I don't know everything

it looks like this kling was built from the ground up ...so they probably re-designed the rails...look at the pictures..

http://www.carlopool.com/KlingProject.htm

http://www.carlopool.com/images/Tables/Kling/RailRework1.jpg

I think the up bolts they are talking about may go right into the subrail but it's hard to tell

a man by the name of Art Bell apparently did the wood work. I will ask this carlopool to comment on this thread so he can explain how he did it.?

There's pictures there of different pool tables, but not all of the Kling. I'm telling you, you can't bolt the antique T-rails up from the bottom of the slate. If you look at the picture showing 2 different sets of slates, you'll see the set in the back ground has the T-rail bolts going into the sides of the slates. Then look at the remanufactured rails, you'll see that there's no bolt holes coming in from the bottom of the rails.

Glen

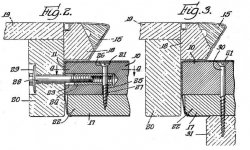

In this picture, which is a picture of the slate he's working on for the Kling, the big holes drilled in the slate is to lead in the anchor nuts to bolt the rails on from the side of the slate. The small slate screw holes on the outside edge of the slate is to mount the slate to the frame of the table, and the smaller holes going through the slate is to mount the slate backer boards. There are NO other holes going through the slate to bolt the rails on from the bottom side of the slate....I'm telling you, it can't be done with an antique set of slates.

perfectpocketz

Banned

If someone for whatever reason wanted to use bolts from under and the side bolts together.....it could be done....you need and 10' slate....to cut down....leaving the slate 1 1/2 inches wider and longer around a 9' frame....you could cut under the sub-rail where the footprint is back maybe and 1 inch...removing the wood from where it bolts in from the side of the table.....now you would have a thin t-rail....with a longer footprint...where you could add 2 inserts to the footprint....between the 3 side mount bolts.....can be done on a modification of the slates and rails....but for what?

If someone for whatever reason wanted to use bolts from under and the side bolts together.....it could be done....you need and 10' slate....to cut down....leaving the slate 1 1/2 inches wider and longer around a 9' frame....you could cut under the sub-rail where the footprint is back maybe and 1 inch...removing the wood from where it bolts in from the side of the table.....now you would have a thin t-rail....with a longer footprint...where you could add 2 inserts to the footprint....between the 3 side mount bolts.....can be done on a modification of the slates and rails....but for what?

Still couldn't be done Mark, because to do that, you'd have to have a sub-rail width of 3 1/2" inches, in which case the pocket ears wouldn't fit the pockets. In order for the pockets to fit the rails on a 9ft T-railed table, the rails would have to bolt to the side of the slates no matter what. What you're talking about Mark, wouldn't work because you'd have to make the rails longer or they'd never fit the pockets in place. Just imagine a set of 9ft T-rails on a 10' antique slate, think of how the pockets would fit with so much distance between the ends of the rails at the corner pockets.

Glen

perfectpocketz

Banned

Still couldn't be done Mark, because to do that, you'd have to have a sub-rail width of 3 1/2" inches, in which case the pocket ears wouldn't fit the pockets. In order for the pockets to fit the rails on a 9ft T-railed table, the rails would have to bolt to the side of the slates no matter what. What you're talking about Mark, wouldn't work because you'd have to make the rails longer or they'd never fit the pockets in place. Just imagine a set of 9ft T-rails on a 10' antique slate, think of how the pockets would fit with so much distance between the ends of the rails at the corner pockets.

Glen

It can be done.....we both know it can.....but no one in their right mind would want to do it.....

Another visual reference since slates don't overhang on a jumbo frame. With the correct slate & slate liner flush with the frame edge there's no way to add a vertical bolt/screw unless going thru the frame. Even if you did then at best you're going into the subrail.

Last edited:

perfectpocketz

Banned

Another visual reference since slates don't overhang on a jumbo frame. With the correct slate & slate liner flush with the frame edge there's no way to add a vertical bolt/screw unless going thru the frame. Even if you did then at best you're going into the subrail.

I've seen plenty of antique tables....the guy said he was cutting a 10' slate down for a 9' frame......that's what I said could be modified for up bolts....and it could be done modifying the slate and the rails....I know a little too....Glen saying it can't be done....is not written in stone.......cause it could with a lot of work.......I would never do it.....and no it can't be done on a jumbo frame.....with the original slates.....never said it could.

couldn't somebody, in theory, add a couple more rail bolts per rail, screwed into the slate from the side just as the originals are?

although i guess it would make me nervous to swiss cheese the slate any more than it is already...

either way, i personally would have a hard time with the ethics of altering an antique to that extent. perhaps it would be better to have a duplicate set of rails made, so you can alter those and not the originals.

although i guess it would make me nervous to swiss cheese the slate any more than it is already...

either way, i personally would have a hard time with the ethics of altering an antique to that extent. perhaps it would be better to have a duplicate set of rails made, so you can alter those and not the originals.