You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

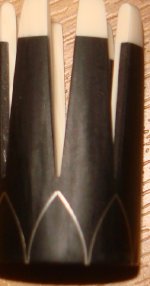

silver veneers

- Thread starter CavinTan

- Start date

how do cuemakers do silver accents on points or inlaysv

With silver

how do cuemakers do silver accents on points or inlaysv

Most use a Pantogragh or CNC. Strangely eneogh, silver comes in different grades of hardness.

Last edited:

Most use a Pantogragh or CNC. Strangely eneogh, silver comes in different grades of hardness.

when an inlay pocket is cut out, do the just line the inlay with silver and glue it in? how would mitre-ing be done to get sharp points?

when an inlay pocket is cut out, do the just line the inlay with silver and glue it in? how would mitre-ing be done to get sharp points?

A machine with the proper spindle can achieve amazing things. I've heard of a couple of Cue makers using bits as small as .005. I call that amazing.

As far as mitering silver, I have no idea. I've never worked with it. I won't say it can't be done, there are some Cue makers I call geniuses. Thomas Wayne, Black Boar, and Dennis Searing. If Bill Stroud was still making cues, I would also add him.

Hand Dressing and Blending

Hello Cal, :smile:

Disclaimer: I am not a Cuemaker

The gun guys and other crafts people have been doing those Silver wire inlaying "Throughout History"..

So, an Internet search might have links of 'How to do".

I just buy the silver wire ( Dead Soft) , and, do the CAD tool paths , CNC machine the lines to the proper depth , so, you have a bit "Sticking up over the surface".

Cut your silver wire or strips to size, file/miter by hand dressing or, make a jig to file that angle to the required complementing angle needed.

Silver can/will blend in with the adjacent piece, if done right, or, like most of us , get "Lucky", and, they blend in "Seamlessly"..

Also, depending if you doing straight inlaying, or, A Axis Substitution, as, the A axis sub method , the silver pieces are not going to "meet/line up" the full required depth, as, we are working over the circumfrence.

You going have to understand this, or see this in your head, or, there is no sense continuing doing "Exotic" things on cues.. NO DISRESPECT INTENDED". As, you got to have a Machinst mind to continue on..

Now, if you doing $$$$ cues, you got to hope guys like Thomas, Ernie and Bob and Tony, and, Jerry, and, Oh, Larry Vigus chime in.. They must know.. Me, I "Just do it"..

Hello Cal, :smile:

Disclaimer: I am not a Cuemaker

The gun guys and other crafts people have been doing those Silver wire inlaying "Throughout History"..

So, an Internet search might have links of 'How to do".

I just buy the silver wire ( Dead Soft) , and, do the CAD tool paths , CNC machine the lines to the proper depth , so, you have a bit "Sticking up over the surface".

Cut your silver wire or strips to size, file/miter by hand dressing or, make a jig to file that angle to the required complementing angle needed.

Silver can/will blend in with the adjacent piece, if done right, or, like most of us , get "Lucky", and, they blend in "Seamlessly"..

Also, depending if you doing straight inlaying, or, A Axis Substitution, as, the A axis sub method , the silver pieces are not going to "meet/line up" the full required depth, as, we are working over the circumfrence.

You going have to understand this, or see this in your head, or, there is no sense continuing doing "Exotic" things on cues.. NO DISRESPECT INTENDED". As, you got to have a Machinst mind to continue on..

Now, if you doing $$$$ cues, you got to hope guys like Thomas, Ernie and Bob and Tony, and, Jerry, and, Oh, Larry Vigus chime in.. They must know.. Me, I "Just do it"..

Attachments

Last edited:

You can machine a Bezel for the inlay, instead of inlaying metal around it.

sorry, i dont quite understand what you mean by bezel? is there any way to personally contact you to talk?

Bezel

Hello Cal,

Nice to meet you..

I do not know the porper normanclature for Joint Portector components/parts. So, I used that to describe the rim or frame around the Cabochan.

From the Internet:

Bezel may refer to:

Bezel (jewelry), the rim which encompasses and fastens a jewel, watch crystal, lens or other object

The sloping facets of the crown of a cut gem after gem cutting

Bezel (screen), a space or frame around a display device, such as on a television or mobile device

The removable plastic faceplate or front panel of a slot, such as CD drive or DVD player

I'm sorry, I can not help you, There is too much to know and say and explain stuff, it would be better if you just go around looking/reading and searching the internet.

When I started. I just went out and bought the cheap CAD software( $89.00) and Mach 3 (Mach 3 comes with lazyCAM ) bought a K2 brand CNC Machine and started learning myself.

No one did, or, wanted to help me. :smile:

But, I kept on trying and today, you can see what I make/do.

There is so much you have to already know.

Plus, I can not get involved now, I have lots of stuff to do everyday.

There are a lot of cuemakers.. Wait till they post.

Hello Cal,

Nice to meet you..

I do not know the porper normanclature for Joint Portector components/parts. So, I used that to describe the rim or frame around the Cabochan.

From the Internet:

Bezel may refer to:

Bezel (jewelry), the rim which encompasses and fastens a jewel, watch crystal, lens or other object

The sloping facets of the crown of a cut gem after gem cutting

Bezel (screen), a space or frame around a display device, such as on a television or mobile device

The removable plastic faceplate or front panel of a slot, such as CD drive or DVD player

I'm sorry, I can not help you, There is too much to know and say and explain stuff, it would be better if you just go around looking/reading and searching the internet.

When I started. I just went out and bought the cheap CAD software( $89.00) and Mach 3 (Mach 3 comes with lazyCAM ) bought a K2 brand CNC Machine and started learning myself.

No one did, or, wanted to help me. :smile:

But, I kept on trying and today, you can see what I make/do.

There is so much you have to already know.

Plus, I can not get involved now, I have lots of stuff to do everyday.

There are a lot of cuemakers.. Wait till they post.

Last edited:

Hi Alton, revisiting an old post of mine, finally got what you meant by A -axis sub after trying it out my own. How do you overcome not inlaying the full depth? been wondering about this for awhile..Hand Dressing and Blending

Hello Cal,

Disclaimer: I am not a Cuemaker

The gun guys and other crafts people have been doing those Silver wire inlaying "Throughout History"..

So, an Internet search might have links of 'How to do".

I just buy the silver wire ( Dead Soft) , and, do the CAD tool paths , CNC machine the lines to the proper depth , so, you have a bit "Sticking up over the surface".

Cut your silver wire or strips to size, file/miter by hand dressing or, make a jig to file that angle to the required complementing angle needed.

Silver can/will blend in with the adjacent piece, if done right, or, like most of us , get "Lucky", and, they blend in "Seamlessly"..

Also, depending if you doing straight inlaying, or, A Axis Substitution, as, the A axis sub method , the silver pieces are not going to "meet/line up" the full required depth, as, we are working over the circumfrence.

You going have to understand this, or see this in your head, or, there is no sense continuing doing "Exotic" things on cues.. NO DISRESPECT INTENDED". As, you got to have a Machinst mind to continue on..

Now, if you doing $$$$ cues, you got to hope guys like Thomas, Ernie and Bob and Tony, and, Jerry, and, Oh, Larry Vigus chime in.. They must know.. Me, I "Just do it"..

HI Calvin,

Disclaimer: I a not a cue maker..

Also, when I talk/type, I mean no disrespect to you or anyone.

Please know this..

I do not worry about filling the whole depth of the silver wire's groove/slot,/channel when the a-axis slot meets the standard X Y Axis straight slots.

Just be sure the surface/top meet up at the finish outside diameter size.

Also know, or, be aware, that, if there is a lot of "gap/space " under the wire, the wire might be pushed down below the finished surface and you will have a "Low spot", or, dip in the continuity of the surface /line.

Usually, the glue or, adhesive, will fill that void or empty space. If / when it hardens , it will 'Fill that "void/empty space" and have enough resistance to prevent the wire being pushed down.

I have no idea what others do.

I just had to do what ever i could think up as I go along.

I had to learn the CNC stuff myself.

I do what ever I have to do to achieve the final outcome/looks I needed to make my Cue Caps.

Everyone,

If anyone ask where is Alton, I am retired.

I retired in 2015.

People still asked me for Caps as a favor.

Many went back to being spoiled Brats .

This time,

I will not reply or answer messages.

No disrespect to anyone.

Too many guys looking for free stuff and no Money.

Amazing times!!!

2021 going be worst..

I told everyone I am retired back in 2015

Alton < Retired. No more messaging me .. I mean that. Thanks

Disclaimer: I a not a cue maker..

Also, when I talk/type, I mean no disrespect to you or anyone.

Please know this..

I do not worry about filling the whole depth of the silver wire's groove/slot,/channel when the a-axis slot meets the standard X Y Axis straight slots.

Just be sure the surface/top meet up at the finish outside diameter size.

Also know, or, be aware, that, if there is a lot of "gap/space " under the wire, the wire might be pushed down below the finished surface and you will have a "Low spot", or, dip in the continuity of the surface /line.

Usually, the glue or, adhesive, will fill that void or empty space. If / when it hardens , it will 'Fill that "void/empty space" and have enough resistance to prevent the wire being pushed down.

I have no idea what others do.

I just had to do what ever i could think up as I go along.

I had to learn the CNC stuff myself.

I do what ever I have to do to achieve the final outcome/looks I needed to make my Cue Caps.

Everyone,

If anyone ask where is Alton, I am retired.

I retired in 2015.

People still asked me for Caps as a favor.

Many went back to being spoiled Brats .

This time,

I will not reply or answer messages.

No disrespect to anyone.

Too many guys looking for free stuff and no Money.

Amazing times!!!

2021 going be worst..

I told everyone I am retired back in 2015

Alton < Retired. No more messaging me .. I mean that. Thanks

Last edited:

That's great thanks for the insight as always, looking forward to more of your posts here on azb hopefully. I have some 'cuecaps' in the making rn tooHI Calvin,

Disclaimer: I a not a cue maker..

Also, when I talk/type, I mean no disrespect to you or anyone.

Please know this..

I do not worry about filling the whole depth of the silver wire's groove/slot,/channel when the a-axis slot meets the standard X Y Axis straight slots.

Just be sure the surface/top meet up at the finish outside diameter size.

Also know, or, be aware, that, if there is a lot of "gap/space " under the wire, the wire might be pushed down below the finished surface and you will have a "Low spot", or, dip in the continuity of the surface /line.

Usually, the glue or, adhesive, will fill that void or empty space. If / when it hardens , it will 'Fill that "void/empty space" and have enough resistance to prevent the wire being pushed down.

I have no idea what others do.

I just had to do what ever i could think up as I go along.

I had to learn the CNC stuff myself.

I do what ever I have to do to achieve the final outcome/looks I needed to make my Cue Caps.

Everyone,

If anyone ask where is Alton, I am retired.

I retired in 2015.

People still asked me for Caps as a favor.

Many went back to being spoiled Brats .

This time,

I will not reply or answer messages.

No disrespect to anyone.

Too many guys looking for free stuff and no Money.

Amazing times!!!

2021 going be worst..

I told everyone I am retired back in 2015

Alton < Retired. No more messaging me .. I mean that. Thanks