OTLB

Banned

As many Technicians understand that when putting on Simonis 860 for example the cloth stretches only so far and thats it; why isn't there a std for this that a manufacturer like Simonis dictates. For example: When doing a std GC size table which is something we all do all the time why isn't there a number to go to. Length you should stretch 6 inches and the sides 2.5, of course those numbers are not accurate but you get the idea.

Have emailed Simonis before about this and fail to receive a response OF ANY KIND. Everyone talks about how much they stretch a cloth and bla bla bla. I want to know how much is right as a factory spec and not from a mechanic but since they don't know we could establish it ourselves. Really don't want to hear about this topic in words and variables, there is a certain amount of elongation and that coupled with strength will give us a number to shoot for.

and variables, there is a certain amount of elongation and that coupled with strength will give us a number to shoot for.

If we use Ron's (LCCS) method we could determin what this is since Simonis doesn't know. Then we could also see if there is any significant difference between what one guy can do versus another both in method and strength.

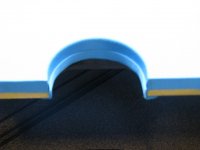

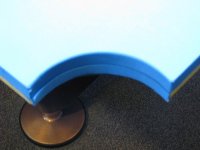

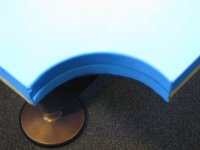

We are going to have some fun now with this one. As I said I thought RON's idea of marking the edge with a marker was clever. When laid flat and at rest, the cloth measures let's just say 100 x 50 inches for example( I know its more). Then you stretch it, attach it, mark it and find how much you stretched it.

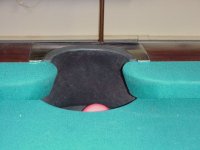

This could be one of the disciplines in a mechanic tournament. Of course you have to be able to finish the pockets off also.

Have emailed Simonis before about this and fail to receive a response OF ANY KIND. Everyone talks about how much they stretch a cloth and bla bla bla. I want to know how much is right as a factory spec and not from a mechanic but since they don't know we could establish it ourselves. Really don't want to hear about this topic in words

If we use Ron's (LCCS) method we could determin what this is since Simonis doesn't know. Then we could also see if there is any significant difference between what one guy can do versus another both in method and strength.

We are going to have some fun now with this one. As I said I thought RON's idea of marking the edge with a marker was clever. When laid flat and at rest, the cloth measures let's just say 100 x 50 inches for example( I know its more). Then you stretch it, attach it, mark it and find how much you stretched it.

This could be one of the disciplines in a mechanic tournament. Of course you have to be able to finish the pockets off also.