You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tac strip update

- Thread starter OTLB

- Start date

Blah Blah Anyways it does look great just curious on how the pockets came out. I guess I have more question that would need close up pictures to see if you get the same stradation lines like when you use staples kind look like runs in nylons. Looks great other then just having some question or needing to see it in person so I can look close at certain things.

Better then expexted keep it up,

Craig

Better then expexted keep it up,

Craig

I think its a great idea and worth testing over time to see how it holds up. Hang in there. You know what they say "Opinions are like a$$holes, everyone has one."there are no waves, the grain of the cloth is straight at every pocket. Are these the pics you want? with extra brads and spray glue the cloth is held without any panty lines. I pulled the cloth with me on my back, legs against the table and all of my arm strength(2 hands) and 220 pounds.

Lou

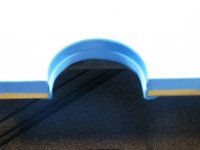

Today I set up a Diamond pro using modified tac strips. Using a brad gun you can add additional tacs where ever you like which improves the bite of these guys, in addition I sprayed them with adhesive which added to their holding power. The guy that just bought my GC V couldn't believe it when I showed him them on my table. I also made them for the pockets on my table.

Yes noone has to use these but they work great. No staples to take out next time or glue.

I am sorry if some of you don't like me or what I do. If you guys don't like me then give me bad rep and knock down my reputation. But please don't attack me and post lies. I am really disgusted with recent comments and as some of my colleagues have warned me about posting in the forum I disregarded their advice. Now its time to take abreak again I think.

I take pride in my work, my products etc and anyone who thinks I don't can you know what.

Oh yeah, setting this table up(my first one) was a piece of cake, my hat is off to Diamond on a great table and I would have kept it for myself but there will be another I am sure. Would like to go to the fatory this summer if possible and see Glen there. Hope to really see some of you on my way.

Hello OTLB,

Though I personally hate actually doing any table mechanic work, I do like to see what you guys are coming up with for I'm always wanting to learn more about all billiard-related things. Though I'm sure much has changed and that there have been various improvements in products and technique since I've done such work, I did do some rebuilding of antiques years ago and was even put in charge of the work done by mechanics for the International 3-Cushion event here in Las Vegas back in 1970. Even got a two-page center-page write-up in the June? Issue of the National Billiard News for my work back then. That was mainly because of how Raymond Ceulemans was telling others that he had no idea American Tables could be made to play that well (he set a new world-breaking record for average in 3-cushion that year on the old tables we had rebuilt).

Anyway, in addition to my obvious liking to brag, I wanted to show that I do know something about table mechanic work so you may better enjoy my opinion that you are obviously one of those very unusual guys that can come up with new and yet very workable ideas. I'm quite impressed. Who knows; this new idea of yours may become quite standard for years to come. Time will tell. This idea required imagination and a lessened need for the agreement of others. As I've often explained, some once thought the world was flat from their inability to disagree with the masses.

Thanks for sharing,

Eddie Robin

Some table s I dont think it will work blinds to close to the slate out of room But for a pool room application I think with the right tables were ther is room it would work over and over less clean up faster recover time.

Like to play on it when new and old to see how it stayed up.

Thanks for staying on your idea and sharing it.

Craig

Like to play on it when new and old to see how it stayed up.

Thanks for staying on your idea and sharing it.

Craig

Thats quite a compliment coming from the legendary Eddie Robin.Hello OTLB,

Though I personally hate actually doing any table mechanic work, I do like to see what you guys are coming up with for I'm always wanting to learn more about all billiard-related things. Though I'm sure much has changed and that there have been various improvements in products and technique since I've done such work, I did do some rebuilding of antiques years ago and was even put in charge of the work done by mechanics for the International 3-Cushion event here in Las Vegas back in 1970. Even got a two-page center-page write-up in the June? Issue of the National Billiard News for my work back then. That was mainly because of how Raymond Ceulemans was telling others that he had no idea American Tables could be made to play that well (he set a new world-breaking record for average in 3-cushion that year on the old tables we had rebuilt).

Anyway, in addition to my obvious liking to brag, I wanted to show that I do know something about table mechanic work so you may better enjoy my opinion that you are obviously one of those very unusual guys that can come up with new and yet very workable ideas. I'm quite impressed. Who knows; this new idea of yours may become quite standard for years to come. Time will tell. This idea required imagination and a lessened need for the agreement of others. As I've often explained, some once thought the world was flat from their inability to disagree with the masses.

Thanks for sharing,

Eddie Robin

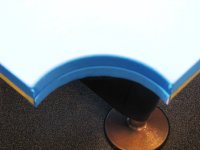

thanks, remember once you tighten the rails they also help keep the cloth in place. I had to stop using pliers as I was ripping the cloth because it was so tight. This is a pic from another install of a GC, the wood floor was slippery and I kept pulling my body into the table so I couldn't lay back. Anyways these are the pliers I mean, not normal ones.

So, what was the cloth, 860 or 860HR? How much did you stretch it from side to side? If the strenght in your arms was pulling as hard as you could with the duck billed pliers, and the cloth was at the point of tearing on the tack strips, then the weakest point was the tack strips

Lets see them pockets and how they finished up

Some of my pockets to compare yours to

Everyone has a tried and true method some look sexy, perfect, repeatable, praticle but only a few wont let you reuse a used bed cloth. I dont think you can restreach a used cloth from one of Glens table method especialy if Cuephoric and I did the streach on it., Cloth is cut shorter then you think on that.

Anyways overall I still think it looks okay intial cost a little high but over time I think it pays for it's self.

I don't think I would adopt it until I play on it for awhile with my usual pool buddies to see what they thought overtime.

I think it's the perfect hook and book for the pool halls that dont want to pay alot but are willing to sign a 5yr contract on recovers and repairs this way it would ofset the cost of the tack strips. You need to use a wide head nail or screws to hold the strips, I used to install carpet and every now and then I would destroy the strips from over streaching.

With Glens way everystep looks perfect and professional since I adopted Glens way my tips go throug the roof 100-300 tips no joke beats the normal 10-20 for a lunch. plus I get alot more calls from past installs wanting to change cloth more often becuase they use the table 20-50 a week more mainly because it was the best install they ever had. You might get similar results with the strips but I would save it for a poolhall type setting for now but thats me.

"T" rail tables it wouldn't work on I believe.

Keep up the ideas,.

Craig

Anyways overall I still think it looks okay intial cost a little high but over time I think it pays for it's self.

I don't think I would adopt it until I play on it for awhile with my usual pool buddies to see what they thought overtime.

I think it's the perfect hook and book for the pool halls that dont want to pay alot but are willing to sign a 5yr contract on recovers and repairs this way it would ofset the cost of the tack strips. You need to use a wide head nail or screws to hold the strips, I used to install carpet and every now and then I would destroy the strips from over streaching.

With Glens way everystep looks perfect and professional since I adopted Glens way my tips go throug the roof 100-300 tips no joke beats the normal 10-20 for a lunch. plus I get alot more calls from past installs wanting to change cloth more often becuase they use the table 20-50 a week more mainly because it was the best install they ever had. You might get similar results with the strips but I would save it for a poolhall type setting for now but thats me.

"T" rail tables it wouldn't work on I believe.

Keep up the ideas,.

Craig

I turn 40 in october 3 piecer i dont mind but 1 piece to the 2nd or 3rd floor I quote them the same as a 12' snooker table and they pay it [ sucks ] but good. We all ramble on I think when Glen gets a school together or some seminars we should all be there to help contribute to a real PHD in table mechanics....phd pool hall degree...

Duck bill pliers work if you debur the hell out of them and some glue in some 30 grit sandpaper in them then they really work, put if you twist them you tear the cloth. So givem a radius this will stop the cloth tear. If it does tear glue helps hide it.

Craig

Duck bill pliers work if you debur the hell out of them and some glue in some 30 grit sandpaper in them then they really work, put if you twist them you tear the cloth. So givem a radius this will stop the cloth tear. If it does tear glue helps hide it.

Craig

I continue to be asked to show pics? I have showed more pics of things than anyone in this forum/QUOTE]

Not even close:rotflmao1::rotflmao1:

Because pictures are worth a 1,000 words John. I just think a mechanic should know how much stretch is used for the kind of cloth and size of table they're working on, so as to be able to repeat the exact same work on an alike table. The maximum stretch can't be achieved by all, but a minimum can. So as to answer your question again, there should be a minimum stretch based on the mechanic's ability to stretch the cloth on the bed, in which if that stretch is also as tight as the mechanic can pull, then the minimum and maximum become the same...wouldn't you agree? And no two mechanics are the same, so that standard would be different from mechanic to mechanic...right?

Glen

Off to auto cad you guys gave me idea on a cloth streacher that any one can use on 90% of the tables I believe. I think I can make it adjustable for length of streach for the different cloths.It should work for stapling, glueing and your tack strip idea. And no you dont have to wet the cloth. I'll see if i can post a rough idea for you guys...

Craig

Craig

min max yes I agree etc but what is the min and what is the max? that is the question. Now a dif mech can be ranked within those 2 parameters which should be established IMO. At the very least a company like Simonis should be able to have this type of documented data either through their own DOE's or data collected from mech's in the field. If they want to continue to be recognized as a leader they should be able to do this very easily and with short order...........IMO

And finally why? why do they provide instructions for installing their cloth that from most everyone in this forum are not followed??????

Unless a guy ages quickly I believe he is likely to give it his all every time which by your own stds means he has repetitive performance.

But if he is weaker than what the std is for min stretch on a given size table and given cloth he can't do the job. Of course this is why I started the thread.

John, as all mechanics are not created equal, one mechanics minimum might be another mechanics maximum, ever think of it that way? Did you know there's a stretch difference between 860 Green and 860 Tour Blue? Blue stretches more than Green, if you don't use a measurement system like I have, you'd never know the difference, as I can tell the difference right away with my system. John, you get to involved in the "How comes" instead of the "How to's"

Glen

Glen I read you loud and clear. There must be a min stretch that is sufficent for a particular cloth and that is why I stated in the thread I started std green. Yes the blue feels light compared to the green. I think I will weigh it. But as you said, if a mech pulls it as tight as they can its ok.

You are highlighting a problem with Simonis though aren't you? Why do 2 cloths of 860 in dif colors not have the same stretch if they are made the same. Is it with the dyeing process? How is their thread dyed?

Big can of worms here

The best I can explain it is it's like the difference in water colors VS oil base paint. In order to get the color Green you have to use Red in your color compound, Red has the heaviest pigmentation, therefore when the cloth is dyed Green, the color pigmentation is bonded thicker to the wool/nylon fibers creating more of a fill in, as opposed to the lighter color of Blue needed to fill in the wool/nylon fibers. It's like taking a canvas picture, though the whole canvas is the same material, if you paint one half with water based paint, then paint the other half with oil based paint, the oil based side of the canvas is going to fill thicker than the water based side. And because of this difference in dyes, the weave of the Green 860 being filled in more thicker, it has less stretch, and is a little slower when compared to the Blue. But, it's still the same exact cloth, if it has the same exact wool/nylon blend.

Glen