Pardon my ignorance, but what's with all these different pins and joints? Is one type really better than the others? I can't tell the difference in 'hit' between the 3/8-10 pins on my cues and other types I've tried. They all do a great job holding a cue together, how a cue feels seems to depend on a lot more than the joint. Does a steel joint really make a difference over other material types? It doesn't matter to me if it takes 5 seconds to screw a cue together versus 3 seconds. Why don't cue makers (both production and custom) just standardize on one pin and joint size? It'd be great to have all shafts/butts interchangeable. I don't see what benefits cue makers by being different other than tying a customer into their type. Is that really a good thing, or would they be better off in the long run using some standard?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's with all these different pins and joints?

- Thread starter slach

- Start date

There was a blind comparison test done some years ago - several cues, some with metal joints and some without, were masked so the joints couldn't be seen, and then some very experienced players were asked to hit with them and try to identify the types of joints (metal vs. other). Nobody could do it consistently.I can't tell the difference in 'hit' between the 3/8-10 pins on my cues and other types I've tried.

A cue's "hit" is not objectively important - you like what you're used to.

pj

chgo

I play the same regardless of pin. My .02 is it stimulates sales and gives a choice. If every cue were UniLoc it would be ok with me. However those pins are more expensive therefore a happy medium is found using other pins. In no way can I feel the difference.

No universal standards.

They are pool cues. It simply isn't important enough nor of any real significance in performance or safety to create and enforce any kind of standard.

Many feel there are special playing qualities to certain joints. I do not believe that and have never seen anything of any validity to support the notion.

Even where standardization is important to safety and performance, we often see huge variations.

As for the topic at hand, we could go on for days and only scratch the surface.

https://www.google.com/search?biw=1.........0....1..gws-wiz-img.HZLS7uRomiA#imgrc=_

.

I cant play worth a crap

With an ivory joint, irrespective of the pin.

I always wondered why that is and have given it the ild clege try a few times.

With an ivory joint, irrespective of the pin.

I always wondered why that is and have given it the ild clege try a few times.

It's simple, money

Every one wants you to have to come back to them for, shafts, inserts, taps, driver pins, jp's etc etc.

Customer wanted one of my carbon fiber shafts for a 'wavy ' pin.

I checked atlas billiard supply for a tap, cost at that time was. $384.

Every one wants you to have to come back to them for, shafts, inserts, taps, driver pins, jp's etc etc.

Customer wanted one of my carbon fiber shafts for a 'wavy ' pin.

I checked atlas billiard supply for a tap, cost at that time was. $384.

Joints and joint screws especially are the right to individualism. If the cue is constructed properly then you may not feel the difference. 4 things define the balance of the Butt. Joint, this also includes joint screw. -A- joint. The splice above the wrap. Weight bolt and lastly, the wood itself. If a cue is constructed for a standard flat faced joint screw, there are quite a few different materials the screws are made out of, all of which have different weights. If the screw is changed from say aluminum to stainless which is much heavier then the cue plays differently. Take the same cue and change the joint from phenolic to metal which is offered in Aluminum, brass, stainless. Full metal old school, or 3/4 threaded then lastly just sleeved. The eeight changed, the balance changed thus the hit has changed.

It's simple physics and commin sence. So don't think of the blind test with 10 well constructed cues. Think of one cue with multiple changes to just the joint.

It's simple physics and commin sence. So don't think of the blind test with 10 well constructed cues. Think of one cue with multiple changes to just the joint.

When you screw together a flat faced wood joint to a flat faced cue joint, well, how many times per day

& how many days per yr. & how many yrs. with that same cue with a flat faced wood shat is it done?

The answer is not as important as the consideration that when you are relying on the thread to go into

the hole on a flat faced wood cue shaft that’s without any brass fitting to hold it together, like with a piloted

joint, you darn well want it to screw tight. The wider pins just do a better job and that is why all my flat

faced ivory joint cues use 3/8x10 or radial. The threaded opening on my shafts is secure and like new.

& how many days per yr. & how many yrs. with that same cue with a flat faced wood shat is it done?

The answer is not as important as the consideration that when you are relying on the thread to go into

the hole on a flat faced wood cue shaft that’s without any brass fitting to hold it together, like with a piloted

joint, you darn well want it to screw tight. The wider pins just do a better job and that is why all my flat

faced ivory joint cues use 3/8x10 or radial. The threaded opening on my shafts is secure and like new.

I can only speak about 3 styles of joint pins that I invented.

The 3/8-10 was created at Joss Cues when I made a mistake measuring a Gina pin. I measured it at 10 threads to the inch when it was actually a standard 12 threads to the inch.

Dan and I had a bunch of 3/8-10 pins made and started using them on Joss Cues.

Players liked it a lot and they became popular. Both Viking and McDermott adopted the design.

The Radial came about later because I felt the 3/8-10 was too sloppy and would loosen with age. I had received a funny looking pin and insert from Paul Contain to use on a cue for himself. I immediately saw that it was not suitable as sent but that it had a great future as a screw into wood. I worked with Paul until we had a final design. It was my idea to call it the Radial.

The Uniloc came about because Gary at the same firm as Paul Costain sent me a new pin with one turn. Neither Gary or Paul had any idea how to use it in a cue so the sent it to me. I immediately saw the future of the pin if it was hidden inside the joint collar. I was working with a new cue firm in Germany called Eurowest and though it would be perfect for them. I introduced it in Germany at the Essem trade show and it was an instant sensation. I gave it the name Uniloc.

Bill S.

The 3/8-10 was created at Joss Cues when I made a mistake measuring a Gina pin. I measured it at 10 threads to the inch when it was actually a standard 12 threads to the inch.

Dan and I had a bunch of 3/8-10 pins made and started using them on Joss Cues.

Players liked it a lot and they became popular. Both Viking and McDermott adopted the design.

The Radial came about later because I felt the 3/8-10 was too sloppy and would loosen with age. I had received a funny looking pin and insert from Paul Contain to use on a cue for himself. I immediately saw that it was not suitable as sent but that it had a great future as a screw into wood. I worked with Paul until we had a final design. It was my idea to call it the Radial.

The Uniloc came about because Gary at the same firm as Paul Costain sent me a new pin with one turn. Neither Gary or Paul had any idea how to use it in a cue so the sent it to me. I immediately saw the future of the pin if it was hidden inside the joint collar. I was working with a new cue firm in Germany called Eurowest and though it would be perfect for them. I introduced it in Germany at the Essem trade show and it was an instant sensation. I gave it the name Uniloc.

Bill S.

Thanks Bill. That's very interesting.

Its funny that some inventions were accidents, like vulcanized rubber and microwave

ovens.

Its funny that some inventions were accidents, like vulcanized rubber and microwave

ovens.

I had an Adams billiard cue with a big wood pin

I loved the way it felt and i had some pool cues made with the wood pin

It may be in my head but I convinced myself that i played better with them

I would like to buy a really nice cue with the wood pin now

Vigus is making me one

Nemic won't do it again or I would buy several

I want to try 58 inch ones

If Billy reads this and knows a reason not to play the wood pin

I would appreciate a note

Dean

I loved the way it felt and i had some pool cues made with the wood pin

It may be in my head but I convinced myself that i played better with them

I would like to buy a really nice cue with the wood pin now

Vigus is making me one

Nemic won't do it again or I would buy several

I want to try 58 inch ones

If Billy reads this and knows a reason not to play the wood pin

I would appreciate a note

Dean

No universal standards.

They are pool cues. It simply isn't important enough nor of any real significance in performance or safety to create and enforce any kind of standard.

Many feel there are special playing qualities to certain joints. I do not believe that and have never seen anything of any validity to support the notion.

Even where standardization is important to safety and performance, we often see huge variations.

As for the topic at hand, we could go on for days and only scratch the surface.

[/QUOTE]

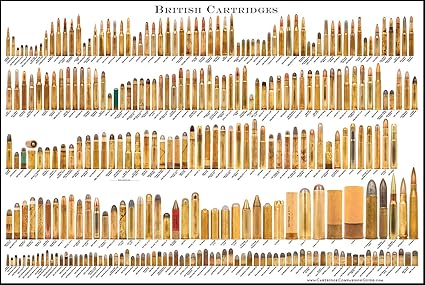

Doc, your dizzying picture reminds me of a Jimmy Reid Story. Jimmy's criteria for when to get a new girlfriend was simple. He would place an orange, and a five-ball on the dresser. When he could tell the difference, she was gone!

All the best,

WW

As others have stated, pin (and joint for that matter) has no impact on performance. Some cue makers would disagree...

They don't even effect the feel or hit.

Pin makes a difference in a few (nitpicky) areas....

1. Balance. Big pins of the same material weigh more, bringing the balance forward. Although, there are many ways to do this, such as a steel joint, or the choice of woods and the overall design and construction of a cue. But that gets into the realm of customs.

2. Speed. More threads and longer pin - more turns needed to disassemble. Some will ponder at this - but if you've ever played a tournament where there are super short races (to 3 in 9 ball) and the format is moving quickly, and there are run-out players, and the room is such where you can't really leave your cue assembled - then you are moving from table to able often it is very annoying to have to be screwing and unscrewing your cues every 15-20 minutes. One quickly appreciates the uniloc pin.

3. Longevity. Some pins or at least joint designs seem to last longer in that they stay tighter. Others tend to get sloppy and loose. How much this affects alignment, I don't know - but it isn't reassuring.

Some opinions:

5/16x18...this pin is the worst. Bad aesthetics (looks like it should be in jar with nuts, bolts and washers in your garage), doesn't help with balance. Not tight until the surfaces meet.

5/16x14 ...this is ok. Wide compatibility. A lot of great cues and cue makers have used this. My favorite is the Mezz version. Super tight and very precise. Their "united" joint as they call it.

Uniloc ...this is fast. Good for balance too. Downsides ...if not timed right, shafts can come loose during play. If the cue is not very stiff in the shaft or forearm, then the vibrations can cause that pin to rattle inside the insert and it makes this metallic buzzing sound. That said, Uniloc is the most sensitive to proper installation in my opinion. Done right, it is nice. Also, Uniloc is a lot heavier than people think. Because it doesn't stick out far and doesn't look beefy ..but inside the butt it is substantial, and the smooth part of the pin is beefy compared to pins that are threaded the full length.

Radial. I like this. Good for balance. Tight. Although I've seen some loose joints this was likely due to how the shaft was tapped. No cons that I know of. For a big pin, it's one of the quicker ones to assemble. Radial's design doesn't beat up the wood. Probably the best pin these days.

3/8x10. Bigger pin, without the benefits of other big pins like the Radial.

Any of the giant G10 pins...blah. The idea behind these is to not alter the balance of the cue by using metal. They do have a lot of surface area and are often tight. I think they are gimmicky.

Some cues have these oversized large pins that are beyond any functional advantage or balance purpose. They are essentially phallic symbols. Yeah, I said it. And yeah, many of you know it is true.

They don't even effect the feel or hit.

Pin makes a difference in a few (nitpicky) areas....

1. Balance. Big pins of the same material weigh more, bringing the balance forward. Although, there are many ways to do this, such as a steel joint, or the choice of woods and the overall design and construction of a cue. But that gets into the realm of customs.

2. Speed. More threads and longer pin - more turns needed to disassemble. Some will ponder at this - but if you've ever played a tournament where there are super short races (to 3 in 9 ball) and the format is moving quickly, and there are run-out players, and the room is such where you can't really leave your cue assembled - then you are moving from table to able often it is very annoying to have to be screwing and unscrewing your cues every 15-20 minutes. One quickly appreciates the uniloc pin.

3. Longevity. Some pins or at least joint designs seem to last longer in that they stay tighter. Others tend to get sloppy and loose. How much this affects alignment, I don't know - but it isn't reassuring.

Some opinions:

5/16x18...this pin is the worst. Bad aesthetics (looks like it should be in jar with nuts, bolts and washers in your garage), doesn't help with balance. Not tight until the surfaces meet.

5/16x14 ...this is ok. Wide compatibility. A lot of great cues and cue makers have used this. My favorite is the Mezz version. Super tight and very precise. Their "united" joint as they call it.

Uniloc ...this is fast. Good for balance too. Downsides ...if not timed right, shafts can come loose during play. If the cue is not very stiff in the shaft or forearm, then the vibrations can cause that pin to rattle inside the insert and it makes this metallic buzzing sound. That said, Uniloc is the most sensitive to proper installation in my opinion. Done right, it is nice. Also, Uniloc is a lot heavier than people think. Because it doesn't stick out far and doesn't look beefy ..but inside the butt it is substantial, and the smooth part of the pin is beefy compared to pins that are threaded the full length.

Radial. I like this. Good for balance. Tight. Although I've seen some loose joints this was likely due to how the shaft was tapped. No cons that I know of. For a big pin, it's one of the quicker ones to assemble. Radial's design doesn't beat up the wood. Probably the best pin these days.

3/8x10. Bigger pin, without the benefits of other big pins like the Radial.

Any of the giant G10 pins...blah. The idea behind these is to not alter the balance of the cue by using metal. They do have a lot of surface area and are often tight. I think they are gimmicky.

Some cues have these oversized large pins that are beyond any functional advantage or balance purpose. They are essentially phallic symbols. Yeah, I said it. And yeah, many of you know it is true.

5/16 18 is tighter than 5/16 14. 14 has a lot more slop.As others have stated, pin (and joint for that matter) has no impact on performance. Some cue makers would disagree...

They don't even effect the feel or hit.

Pin makes a difference in a few (nitpicky) areas....

1. Balance. Big pins of the same material weigh more, bringing the balance forward. Although, there are many ways to do this, such as a steel joint, or the choice of woods and the overall design and construction of a cue. But that gets into the realm of customs.

2. Speed. More threads and longer pin - more turns needed to disassemble. Some will ponder at this - but if you've ever played a tournament where there are super short races (to 3 in 9 ball) and the format is moving quickly, and there are run-out players, and the room is such where you can't really leave your cue assembled - then you are moving from table to able often it is very annoying to have to be screwing and unscrewing your cues every 15-20 minutes. One quickly appreciates the uniloc pin.

3. Longevity. Some pins or at least joint designs seem to last longer in that they stay tighter. Others tend to get sloppy and loose. How much this affects alignment, I don't know - but it isn't reassuring.

Some opinions:

5/16x18...this pin is the worst. Bad aesthetics (looks like it should be in jar with nuts, bolts and washers in your garage), doesn't help with balance. Not tight until the surfaces meet.

5/16x14 ...this is ok. Wide compatibility. A lot of great cues and cue makers have used this. My favorite is the Mezz version. Super tight and very precise. Their "united" joint as they call it.

Uniloc ...this is fast. Good for balance too. Downsides ...if not timed right, shafts can come loose during play. If the cue is not very stiff in the shaft or forearm, then the vibrations can cause that pin to rattle inside the insert and it makes this metallic buzzing sound. That said, Uniloc is the most sensitive to proper installation in my opinion. Done right, it is nice. Also, Uniloc is a lot heavier than people think. Because it doesn't stick out far and doesn't look beefy ..but inside the butt it is substantial, and the smooth part of the pin is beefy compared to pins that are threaded the full length.

Radial. I like this. Good for balance. Tight. Although I've seen some loose joints this was likely due to how the shaft was tapped. No cons that I know of. For a big pin, it's one of the quicker ones to assemble. Radial's design doesn't beat up the wood. Probably the best pin these days.

3/8x10. Bigger pin, without the benefits of other big pins like the Radial.

Any of the giant G10 pins...blah. The idea behind these is to not alter the balance of the cue by using metal. They do have a lot of surface area and are often tight. I think they are gimmicky.

Some cues have these oversized large pins that are beyond any functional advantage or balance purpose. They are essentially phallic symbols. Yeah, I said it. And yeah, many of you know it is true.

G-10 comes in Radial, 3/8 10 or 11 or 7/16. I have no idea why you think they do not have a lot of surface area. They have the same surface area as the same thread size and pitch in metal .

Radial and 3/8 10 are about the same weight in SS or Brass.

3/8 10 come in flat bottom as well.

Uniloc quick release is not as heavy as 3/8 screws of the same material.

As others have stated, pin (and joint for that matter) has no impact on performance. Some cue makers would disagree...

They don't even effect the feel or hit.

Pin makes a difference in a few (nitpicky) areas....

1. Balance. Big pins of the same material weigh more, bringing the balance forward. Although, there are many ways to do this, such as a steel joint, or the choice of woods and the overall design and construction of a cue. But that gets into the realm of customs.

2. Speed. More threads and longer pin - more turns needed to disassemble. Some will ponder at this - but if you've ever played a tournament where there are super short races (to 3 in 9 ball) and the format is moving quickly, and there are run-out players, and the room is such where you can't really leave your cue assembled - then you are moving from table to able often it is very annoying to have to be screwing and unscrewing your cues every 15-20 minutes. One quickly appreciates the uniloc pin.

3. Longevity. Some pins or at least joint designs seem to last longer in that they stay tighter. Others tend to get sloppy and loose. How much this affects alignment, I don't know - but it isn't reassuring.

Some opinions:

5/16x18...this pin is the worst. Bad aesthetics (looks like it should be in jar with nuts, bolts and washers in your garage), doesn't help with balance. Not tight until the surfaces meet.

5/16x14 ...this is ok. Wide compatibility. A lot of great cues and cue makers have used this. My favorite is the Mezz version. Super tight and very precise. Their "united" joint as they call it.

Uniloc ...this is fast. Good for balance too. Downsides ...if not timed right, shafts can come loose during play. If the cue is not very stiff in the shaft or forearm, then the vibrations can cause that pin to rattle inside the insert and it makes this metallic buzzing sound. That said, Uniloc is the most sensitive to proper installation in my opinion. Done right, it is nice. Also, Uniloc is a lot heavier than people think. Because it doesn't stick out far and doesn't look beefy ..but inside the butt it is substantial, and the smooth part of the pin is beefy compared to pins that are threaded the full length.

Radial. I like this. Good for balance. Tight. Although I've seen some loose joints this was likely due to how the shaft was tapped. No cons that I know of. For a big pin, it's one of the quicker ones to assemble. Radial's design doesn't beat up the wood. Probably the best pin these days.

3/8x10. Bigger pin, without the benefits of other big pins like the Radial.

Any of the giant G10 pins...blah. The idea behind these is to not alter the balance of the cue by using metal. They do have a lot of surface area and are often tight. I think they are gimmicky.

Some cues have these oversized large pins that are beyond any functional advantage or balance purpose. They are essentially phallic symbols. Yeah, I said it. And yeah, many of you know it is true.

You've posted way too much gobblety-gook for me to address each item, but #2 caught my attention.

If the extra two seconds it takes to maybe undo a certain type shaft "bothers somebody", that person may have some kind of mental disorder. I have been screwing shafts of every type together for over 50 years and it hasn't been a problem of any sort.

What you going to do in that extra two seconds you saved? Catch a little nap or something?

5/16 18 is tighter than 5/16 14. 14 has a lot more slop.

G-10 comes in Radial, 3/8 10 or 11 or 7/16. I have no idea why you think they do not have a lot of surface area. They have the same surface area as the same thread size and pitch in metal .

Radial and 3/8 10 are about the same weight in SS or Brass.

3/8 10 come in flat bottom as well.

Uniloc quick release is not as heavy as 3/8 screws of the same material.

I’m glad you said that about the 18 thread, Joey.

I don’t know much about this other than as a player...but I feel my ‘68 Joss has a tighter

hit than my 14 threaders.

For me, it’s just a feel.

My best snooker cue ever had a thin steel screw with (I think) 22 threads.

....hit like a one-piece.

5/16 18 is tighter than 5/16 14. 14 has a lot more slop.

My experience has been the opposite. :shrug:

My experience has been the opposite. :shrug:

That's why some 5/16 14 are piloted.

They have so much slop.

The pilot keeps it tight and acts as the register.

Gina has been using 5/16 18 flat face for ages.

Last edited: