What I came up with.

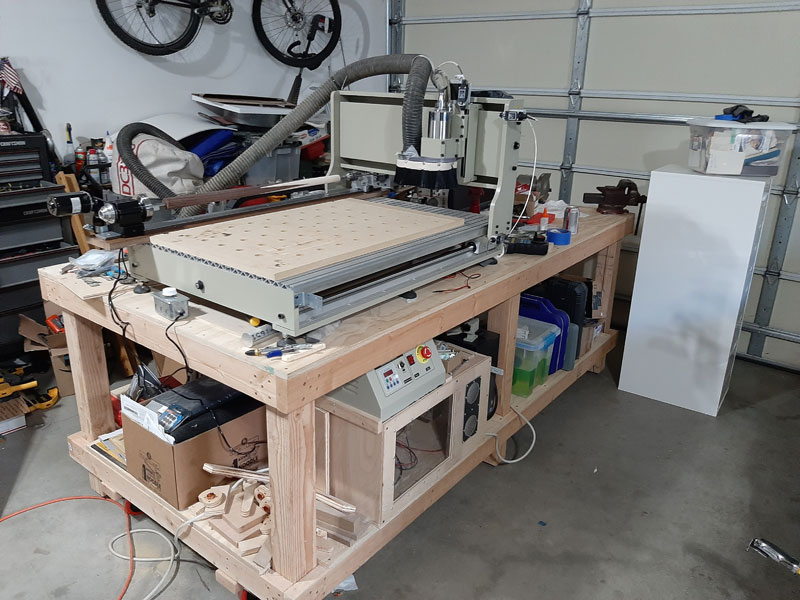

In case you haven't already came up with something, I decided to go with Todd's workstation and it is working out perfectly.

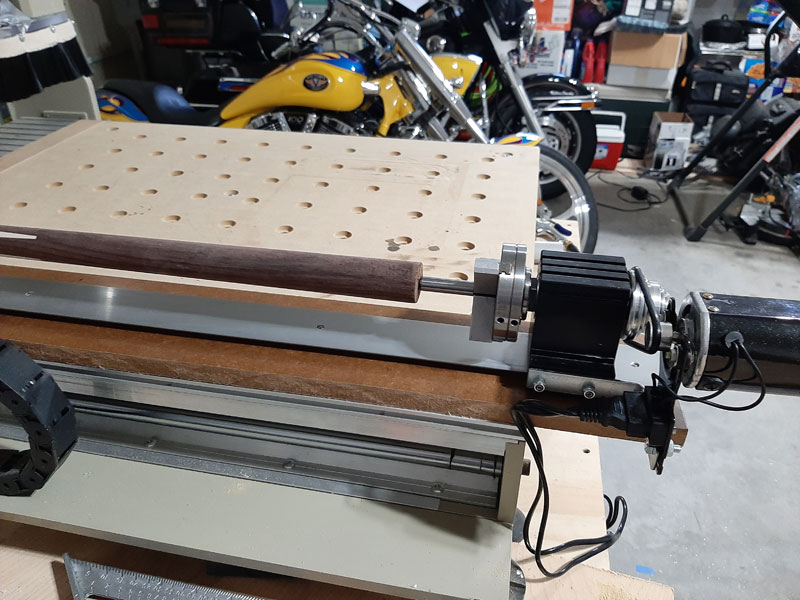

My biggest concern was the limited Z clearance on my Chinese 6090. Turns out this has plenty of clearance for the

tailstock without having to remove the dovetail bed from the board Todd supplies. The headstock (chuck) is a little

high but the gantry won't interfere how it's mounted.

I would have went a completely different direction if I had more room but I work out of a double garage and need room for the bikes

so I'm limited to my 4X8 bench shown here. (The hightower deluxe is on the other side).

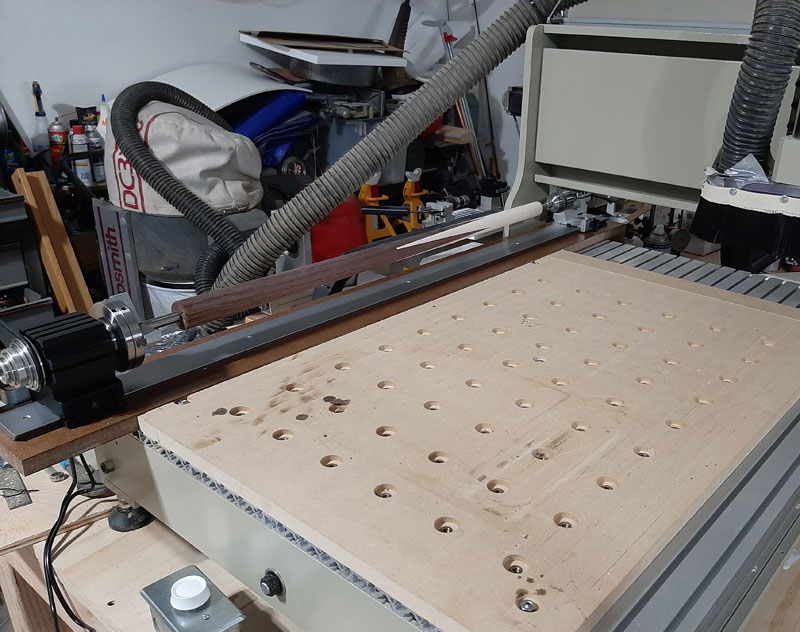

Here's a few shots of the workstation mounted to the 6090 bed.

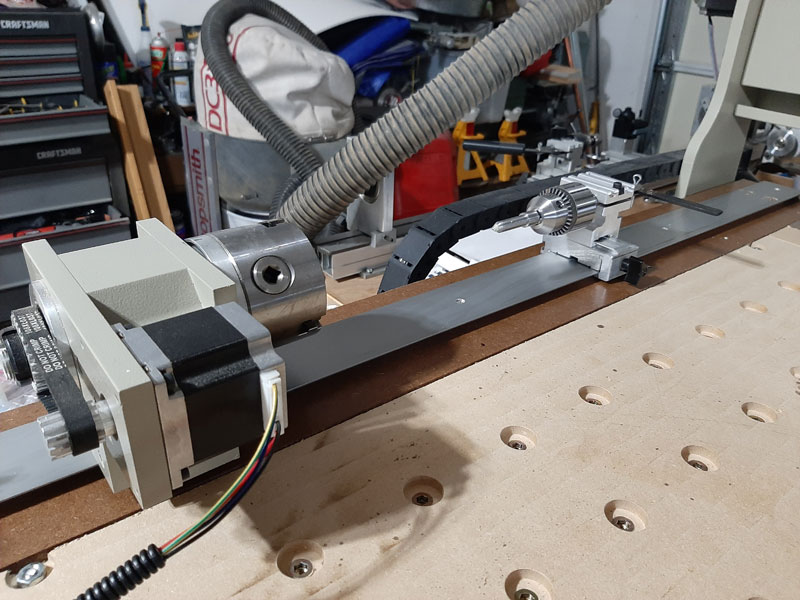

Finally, this is what I decided to do with the 4th axis. I'll design a dovetail standoff similar to the 1" deluxe to mount the 4th axis motor assembly to. Then when I need to switch from tapers to ring billets, points, and or inlays, I'll simply swap the rotating motor assembly with the stepper assembly.

All in all I think it will work great cosidering my contraints. I did a test straight cut on some scrap and it all works as expected.

Where there's a will there's a way!

Also I should mention that mounting it clear over to the side makes it a bit of a pain to mount workpieces however on the plus side

the gantry is much more rigid that close to the upright and it still allows me to do other larger carving projects on the cnc.

Hope this gives others in a similar situation some ideas...