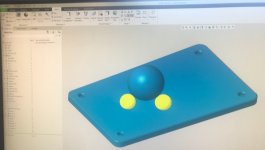

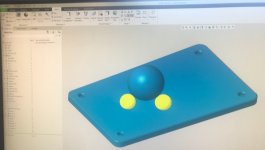

I'm working on a ball sphericity (roundness) tester for fun. Below are a couple of pictures, and a YouTube video link describing the process. I'll update as I go.

My motivation is to see how different ball sets and brands compare both when new, and when worn. Also because I like making things.

View attachment 556942

View attachment 556943

Youtube video with a lot more detail. Part 1:

https://youtu.be/fHgEgi62nO0

The owner of Sequoia Billiards had a ball gauge with an indicator. I believe the three resting points were some kind of bearing so they rotated easily rather than slid on the ball. I wasn't paying enough attention to notice how precise the feeler gauge was. It was really quick to tell how good a ball was.

About 1975 I got the Student Union maintenance guy to make me a go/no go two-hole round gauge. You're right that it can't measure diameters directly, but it can find significant non-sphericity. At the 1976 World Open, the balls were rolling funny and it turned out that many of the eyes of the 3s, 5s, and 7s were bulging enough to hang up on the 2.255 hole :yikes:. (+- 0.005 is the actual spec, but most balls these days seem to be close to +-0.001.)

The indicator-based gauge is a lot more flexible, but a piece of steel with two holes drilled through it (or EDMed?) is a lot more rugged if you're dragging it to tournaments.

Do you need a known good ball to zero the feeler each time?

Here is a set of round gauges for pool balls from Ebay for $13 from seller joebuyer -- he has one set left on the current auction. The five sizes relative to 2.250 are +0.005, 0.000, -0.005, -0.010 and -some_more. They're made of 1/16" fiberglass. The undersized holes are to see just how badly worn the balls are.

![CropperCapture[59].jpg CropperCapture[59].jpg](https://forums.azbilliards.com/data/attachments/412/412843-028d5f173e9d9355645f50016018ab86.jpg)

For those who think the diameters of a sphere tell the whole story, check out this video about a constant-diameter "sphere" that is clearly not round:

https://www.youtube.com/watch?v=fOojOfpcPZM

![CropperCapture[59].jpg CropperCapture[59].jpg](https://forums.azbilliards.com/data/attachments/412/412843-028d5f173e9d9355645f50016018ab86.jpg)