John - your Chinese team makes some great looking cases, no doubt.

However, the case with " RIP Dad " on it -- I am all for honoring your father -- but I can only assume that the person you are designing the case for drew up the image and you transposed it to the case. Unfortunately, it looks like something that was made at a Boy Scout Camp. You should have used some customer service there and made a suggestion to the buyer that you could come up with a design that was more eloquent and simply a better design.

I have never bought a case but have bought custom cues. I can scratch out a drawing of my idea to the cue maker but I hope he would never transpose my design onto the cue exactly.

This post is not meant to be vindictive - just a mere suggestion that you as the foreman and your team of workers should have the last say as to what goes out the door with your name attached to it.

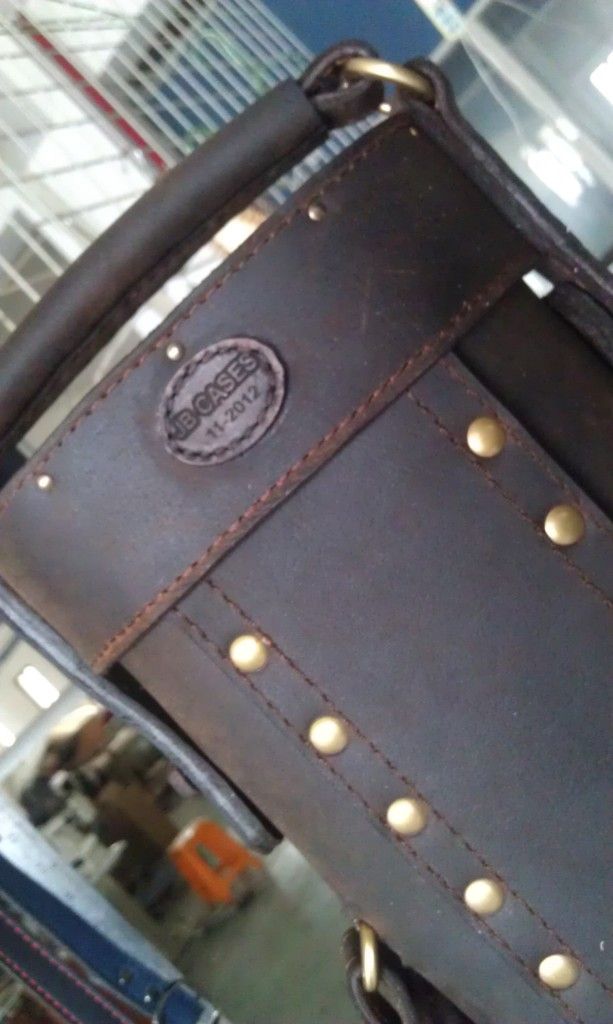

Thanks for the input Steve. Since you haven't yet ordered a case from us this is a good opportunity to explain the process.

When a customer contacts us they have either gone through our site to find other cases we have done to use as the building block or they have an idea of their own that they would like to know if we can do.

We generally have a discussion about it with me or my wife answering questions and offering suggestions until the customer is clear.

Then the customer puts in an order through the order form here

www.jbcases.com/orderform.html Here the customer chooses the exact specifications he wants in his case.

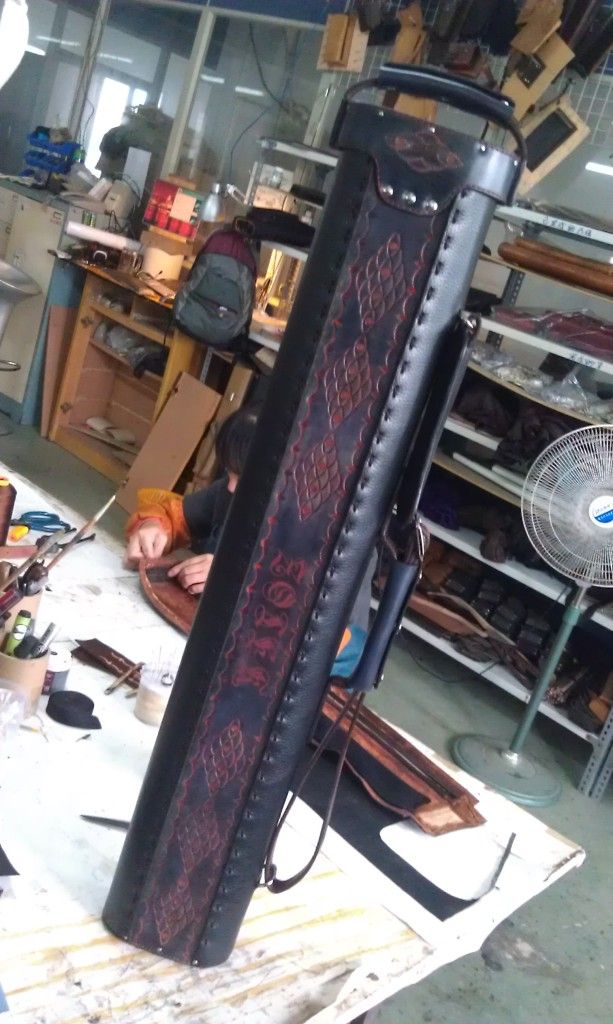

Then we will do a preliminary sketch to make sure that the specifications are all correct. At this point we correct or change any specs that the customer wants. Then we move into the decoration and try to interpret what the customer has described. We will change it as many times as the customer wants until they are satisfied.

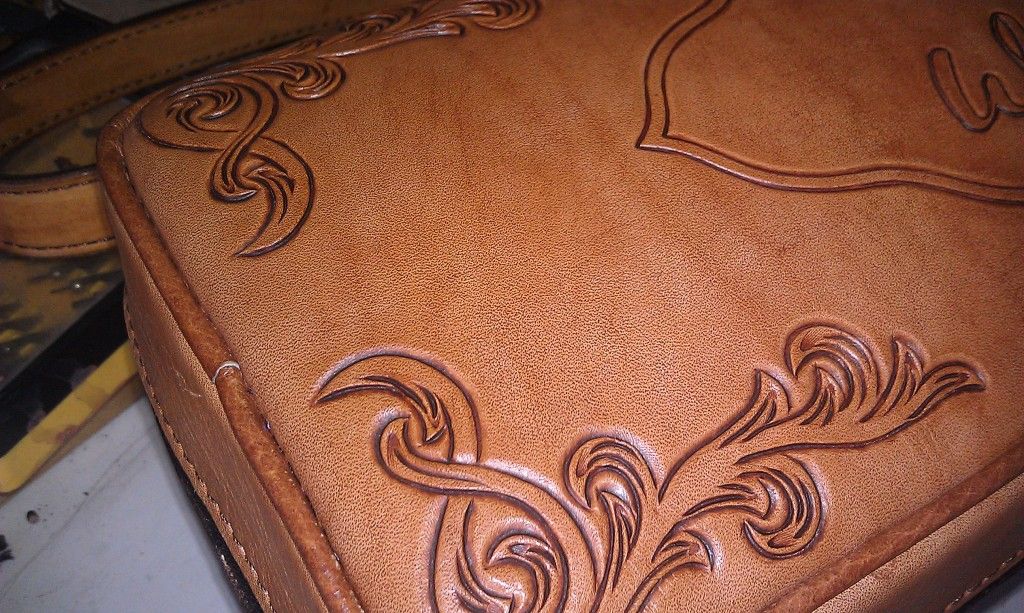

At this point we often do color samples, we will do tooling samples, show various leather choices, essentially we do whatever physical mockups we need to do to insure that the customer is getting exactly what they want.

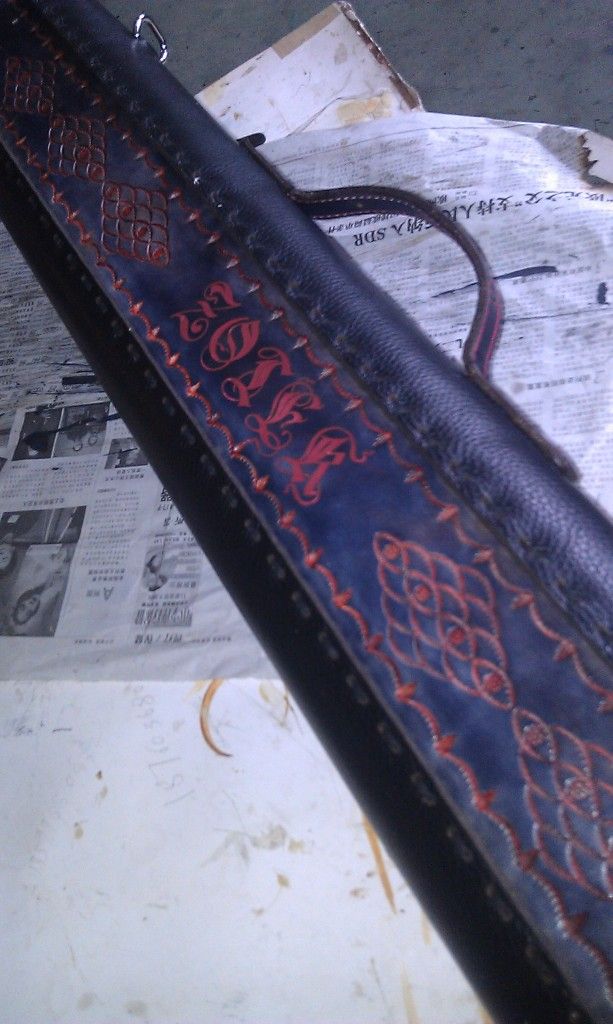

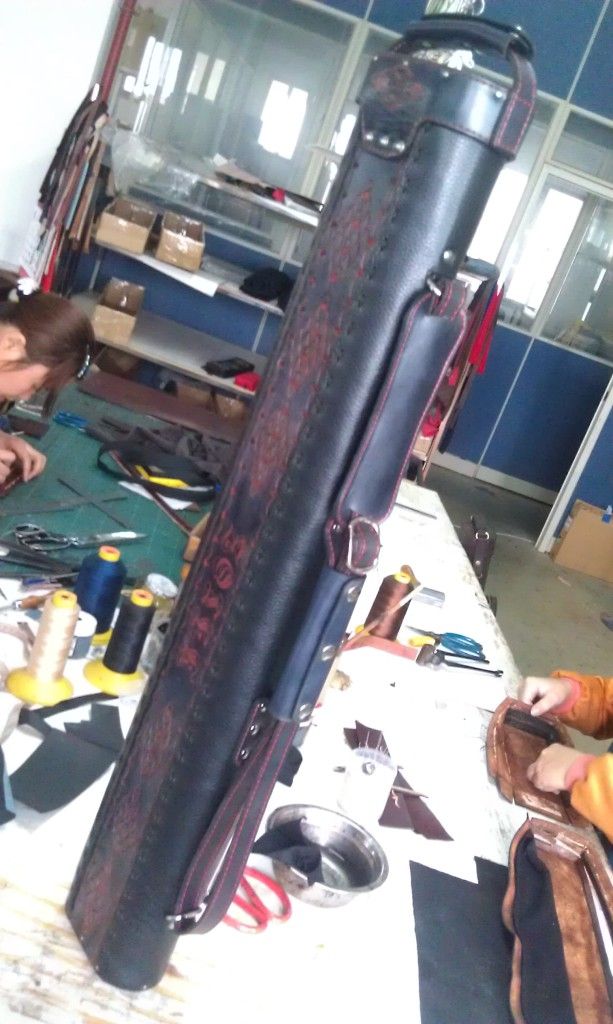

For Evan's case we did about four drawings and asked him for his input on each one. We changed the drawings to reflect his desire and since we are a true custom shop we built the case according to his concept of what would be a fitting tribute to his father's memory. Evan did not send us a drawing, he described what he wanted and we did arrangements until he approved what ultimately went on the case.

I understand that you don't like the design and I am sure that there are many who aren't turned on by it. But the main point is that the customer likes it. What he had in his head came to life and that made him happy.

There are two types of makers in any thing, those who make primarily what they want to their own specifications and with their own sense of what looks good or those who do what ever the customer wants if it's possible to do so. I fall in the latter category. Which means that I will build some cases that are not going to be appealing to the all the of people who look at them. We do have the final say on what we will build and IF I feel strongly about something I will discuss it with the customer and most of the time the customer will agree with me. But this itself is part of the process.

But to reiterate for me the most important thing is that the customer is happy with what they get. We try our best to get as close to their vision as we can and most times we seem to get close enough. We do provide a huge amount of service and guidance as our customers can testify to. Because of doing that we also sometimes do allow some orders to languish but once we get into them and the build commences we keep the communication up and provide status updates to them.

Evan's case turned out beautifully by the way and he is very happy with it. My wife spent a solid week painting it by hand. The leather workers among us know what type of work went into making this case in purple and white.

Again thanks for the input. When you order a case I am certain that you will be well pleased with the amount of service and choice you get.