qbildr knows what he's talking about. Of the 6 ivory joint cues I own, two are from the secondary market.

So I had absolutely no say or any input on how the cues were designed or the actual cue specifications.

However, the other four cues, although I wasn't involved with actually building the cues, the design

from stem to stern was what I came up with with some input from Bob Owen and Jerry Raunzahn. For

what it's worth, those two fellows are the nicest fellows to have build you a cue & workmanship is A+.

The one area where I took total control over was the cue specifications. If anyone has opportunity to

speak with Bob or Jerry, they'd tell you how challenging it was to build the cues to my specifications.

Nonetheless, each cue-maker nailed it and they didn't do it by building a light cue and then relying

upon using a weight bolt to hit my target weight. I ordered cues to be made using a butt weight target

of 14.5 ounces and shafts weighing 4 ounces or heavier. This yields a shaft weight ratio of >21% and

if the shafts came in heavier, then my ratio improves as long as the cue-maker controls the cue butt

weight. Again, I do not understand how a cue-maker is able to exactly control the building of the cue

but obviously the better ones can and do. It's a talent more than anything else because if you go back

and look at the specs I provided, both cue-makers missed the mark.............but not really.

14.5 oz. butt & 4 oz. shafts or heavier (12.75mm with 16-17" taper), flat faced is what I requested.

14.497 oz. & 3.99 oz. (shaft 1 - 21.53%) and 4.13 oz. (shaft 2 - 22.17%) is what Jerry produced.

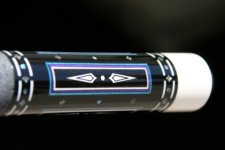

My last cue Bob Owen made has a 14.55 ounce cue butt and has a lot of ivory inlays & fancy rings

and Bob didn't use any weight bolt. So Jerry missed the target butt weight by .003 ounces and Bob

missed it by .05 ounces and like I wrote, he didn't even use a weight bolt building my last cue. That is

friggin' incredible when you look at the design Bob had to tackle & he told me "No problems."

Bob never hesitated or ever expressed reservations about my cue specs and neither did Jerry

Matt B.

p.s. I'll verify the balance point on my cues when next at the pool hall.

So I had absolutely no say or any input on how the cues were designed or the actual cue specifications.

However, the other four cues, although I wasn't involved with actually building the cues, the design

from stem to stern was what I came up with with some input from Bob Owen and Jerry Raunzahn. For

what it's worth, those two fellows are the nicest fellows to have build you a cue & workmanship is A+.

The one area where I took total control over was the cue specifications. If anyone has opportunity to

speak with Bob or Jerry, they'd tell you how challenging it was to build the cues to my specifications.

Nonetheless, each cue-maker nailed it and they didn't do it by building a light cue and then relying

upon using a weight bolt to hit my target weight. I ordered cues to be made using a butt weight target

of 14.5 ounces and shafts weighing 4 ounces or heavier. This yields a shaft weight ratio of >21% and

if the shafts came in heavier, then my ratio improves as long as the cue-maker controls the cue butt

weight. Again, I do not understand how a cue-maker is able to exactly control the building of the cue

but obviously the better ones can and do. It's a talent more than anything else because if you go back

and look at the specs I provided, both cue-makers missed the mark.............but not really.

14.5 oz. butt & 4 oz. shafts or heavier (12.75mm with 16-17" taper), flat faced is what I requested.

14.497 oz. & 3.99 oz. (shaft 1 - 21.53%) and 4.13 oz. (shaft 2 - 22.17%) is what Jerry produced.

My last cue Bob Owen made has a 14.55 ounce cue butt and has a lot of ivory inlays & fancy rings

and Bob didn't use any weight bolt. So Jerry missed the target butt weight by .003 ounces and Bob

missed it by .05 ounces and like I wrote, he didn't even use a weight bolt building my last cue. That is

friggin' incredible when you look at the design Bob had to tackle & he told me "No problems."

Bob never hesitated or ever expressed reservations about my cue specs and neither did Jerry

Matt B.

p.s. I'll verify the balance point on my cues when next at the pool hall.

Attachments

Last edited: