I need to re-locate this table on Saturday. I've contacted a number of different movers and nobody is available on short notice, or in this remote location.

My only option is doing it myself. I've never taken apart a table before, so I'm hoping for some advice.

First, my skillset... My woodworking and mechanical skills, and tools, should be up to the task. (However, if any super-specialized tools are necessary, please let me know!)

Ok, a couple questions to get me started on the right track:

1) I plan on labeling EVERYTHING, draw a diagram, and lots of pictures. Any other advice here?

2) Do I start by removing the rails, then the felt, then the slate?

3) How do people usually move the slate? (At this point, I do not know how many pieces, or thickness. Thankfully, there are no stairs.)

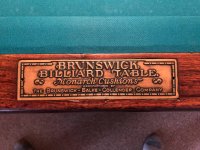

I realize certain aspects of this will be somewhat table-specific. Any tips specific to this old Brunswick is greatly appreciated.

THANKS IN ADVANCE!

My only option is doing it myself. I've never taken apart a table before, so I'm hoping for some advice.

First, my skillset... My woodworking and mechanical skills, and tools, should be up to the task. (However, if any super-specialized tools are necessary, please let me know!)

Ok, a couple questions to get me started on the right track:

1) I plan on labeling EVERYTHING, draw a diagram, and lots of pictures. Any other advice here?

2) Do I start by removing the rails, then the felt, then the slate?

3) How do people usually move the slate? (At this point, I do not know how many pieces, or thickness. Thankfully, there are no stairs.)

I realize certain aspects of this will be somewhat table-specific. Any tips specific to this old Brunswick is greatly appreciated.

THANKS IN ADVANCE!

Attachments

Last edited: