If you mean the size of the tip/CB contact area, that's not determined by tip size - only by hardness and curvature (and hardly matters even then).

Some of us learned to shoot during the dark ages, or at least in backwards areas where there was little info except watch and learn, perhaps paying along the way. I never attained a high level of play. My glory days during the 70's, 80's rose as high as "serious bar banger". Could often hold a 7ft Fisher all night, sometimes put together 3 packs, probably at most.

Whether it was shooting mostly off the wall or just poor information, i still gravitate to a flat tip. Oh, I'll put a dime on it when making a new shaft or re-tipping one of mine. Then find that i get more comfortable as it flattens out. Prefer hard milk duds.

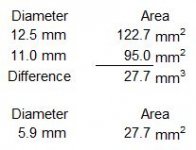

IOW, there is a larger sweet spot & it can be helpful, at least at the level of play & eyesight of his old duffer. Perhaps oddly, though, i don't like tips wider than about 12.75mm.

smt, still interested in learning, though.