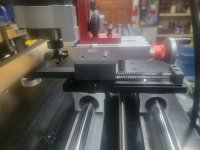

Thought it'd be fun to see if I could cheaply build myself a shaft tapering machine. its not perfect and needs some improvements, including a taper bar with a spring slide to follow the taper but it works. Thought I'd share that this can be built fairly cheaply.

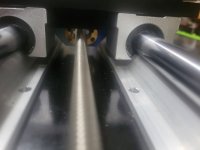

I had the trim router. Pulled the slow speed geared motor and mdf from a treadmill. Purchased SR16 linear rails from Amazon. Got the T8 lead screw and nut from Amazon. Bought an atlas half nut assembly from eBay and modified it to hold the T8 lead nut and cut it in half. Pulleys, Belts, Toggle switches came from AliExpress. 8MM high speed steel also, which I ground to a point on a bench grinder. Also got 8mm collar stops and pillow blocks from there which complete the drive and spring point on the center. slide mechanism also came from AliExpress. Used a hanger bracket from Menards for the router mount. I will upgrade but its been a fun project. Thanks.

I had the trim router. Pulled the slow speed geared motor and mdf from a treadmill. Purchased SR16 linear rails from Amazon. Got the T8 lead screw and nut from Amazon. Bought an atlas half nut assembly from eBay and modified it to hold the T8 lead nut and cut it in half. Pulleys, Belts, Toggle switches came from AliExpress. 8MM high speed steel also, which I ground to a point on a bench grinder. Also got 8mm collar stops and pillow blocks from there which complete the drive and spring point on the center. slide mechanism also came from AliExpress. Used a hanger bracket from Menards for the router mount. I will upgrade but its been a fun project. Thanks.