I have been manufacturing and selling some cue building accessories here in Louisiana. I offer a few different items and have been selling on facebook marketplace. I know some of you guys are not on FB so I wanted to show them here as well. I hope I am not breaking the rules as I am not a big business just someone sellign a few items from my home shop but I do have a website where I added all of my parts that I make to make . This make ordering and tracking which orders have been shipped and whatnot much easier to manage. My site is actionbilliardsupply.com if any of you are interested

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cuesmith indicator mounts - Cue building Clamps and a few other misc items for sale

- Thread starter Facundus Cues

- Start date

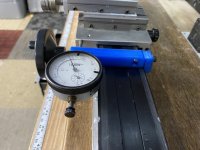

Recently picked up the Dovetail Indicator Mount. 3D printed item -well done IMHO. Have jury-rigged a number of configurations to get an Indicator on my machine, and this fit the bill perfectly! Was a bit concerned on "flex" prior to purchase - ended up being a non-issue.

May not fit your criteria - but works great for me.

My $0.015 ($0.02, adjusted for inflation).

May not fit your criteria - but works great for me.

My $0.015 ($0.02, adjusted for inflation).

Everything has some flex at some point. Once it is all preloaded , it is just fine. Great to see what people are making and how they are making them these days. I like the wall mounted holders , great idea. The travadial for the Taig type lathe beds is another that is good too. Are you moulding a nut , inside for the screw to pull up with on the Z axis carriage ? My son does printing of parts but is too busy to do much for me, but he makes a product and the print is paused, and the nuts go into the printed recesses, then it carries on printing over the nut. Some things have hidden magnets, or slots for square style nuts to be placed. Lots of different materials these days as well as the ability to use a carbon or glass reinforced inner material a different material for the outside with a duel head printer. Since 2018 it has done just over 22.4k hours. It runs almost every night making parts and often finishes in the morning for the next lot. Most things are done in under 12 hours per build plate. Sure is an interesting industry.

Thanks for the review. Glad you like itRecently picked up the Dovetail Indicator Mount. 3D printed item -well done IMHO. Have jury-rigged a number of configurations to get an Indicator on my machine, and this fit the bill perfectly! Was a bit concerned on "flex" prior to purchase - ended up being a non-issue.

May not fit your criteria - but works great for me.

My $0.015 ($0.02, adjusted for inflation).

I actually print a recess that accepts a 10/32 nylock nut. Seems to have worked out pretty well so farEverything has some flex at some point. Once it is all preloaded , it is just fine. Great to see what people are making and how they are making them these days. I like the wall mounted holders , great idea. The travadial for the Taig type lathe beds is another that is good too. Are you moulding a nut , inside for the screw to pull up with on the Z axis carriage ? My son does printing of parts but is too busy to do much for me, but he makes a product and the print is paused, and the nuts go into the printed recesses, then it carries on printing over the nut. Some things have hidden magnets, or slots for square style nuts to be placed. Lots of different materials these days as well as the ability to use a carbon or glass reinforced inner material a different material for the outside with a duel head printer. Since 2018 it has done just over 22.4k hours. It runs almost every night making parts and often finishes in the morning for the next lot. Most things are done in under 12 hours per build plate. Sure is an interesting industry.

Got it - thank youOrder placed, thanks!