Hello all. I was working at the lathe tonight machining some metal and the lathe motor suddenly sounded like I threw it into reverse. I immediately shut it off and I could hear a hum/buzz like the motor was getting power but not spinning. The switch was in the off position while I was hearing this. I hit the safety stop button and let it sit for a while to cool off. I was not doing any heavy work or anything but the motor did feel a little warmer than I remember it should. After about 30 minutes I plugged it back in and reset the safety button and am hearing the same buzz. I assume this is a relay contact sticking and sending power to one phase of the motor.

I turned on the switch and the lathe started to spin up but slower than normal. I decided to shut it off as something is definately wrong but before I could get my hand to the switch there was a small explosion in/around the motor and a puff of black smoke. I slapped the kill button and unplugged the lathe.

For around the last month every once in a while I would hit the on switch and the lathe would either not spin or would take a half a second and then start spinning. When it would not start I would here a buzz but louder than it was tonight with the switch off. If I grabbed the chuck and moved it at all it would spin right up to speed like normal. It only happened a couple times but it never did this before. I have another identical lathe on the same breaker and it always starts correctly so I believe the power in is not the issue.

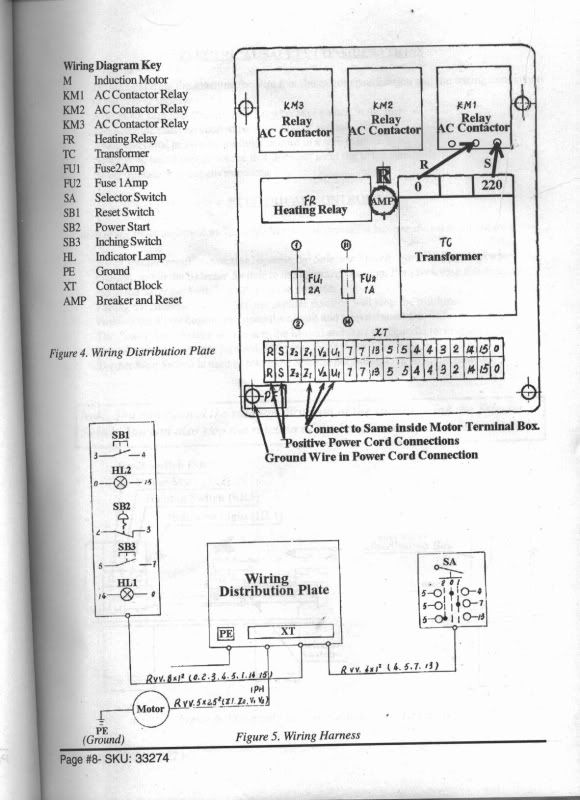

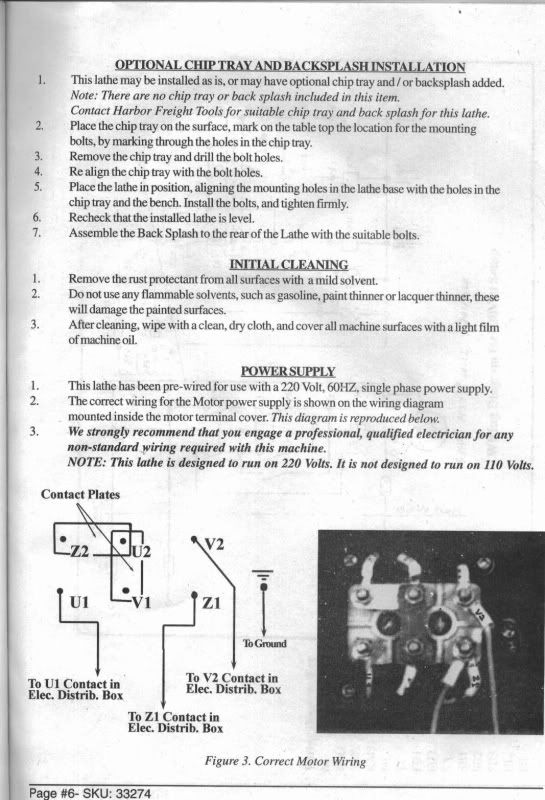

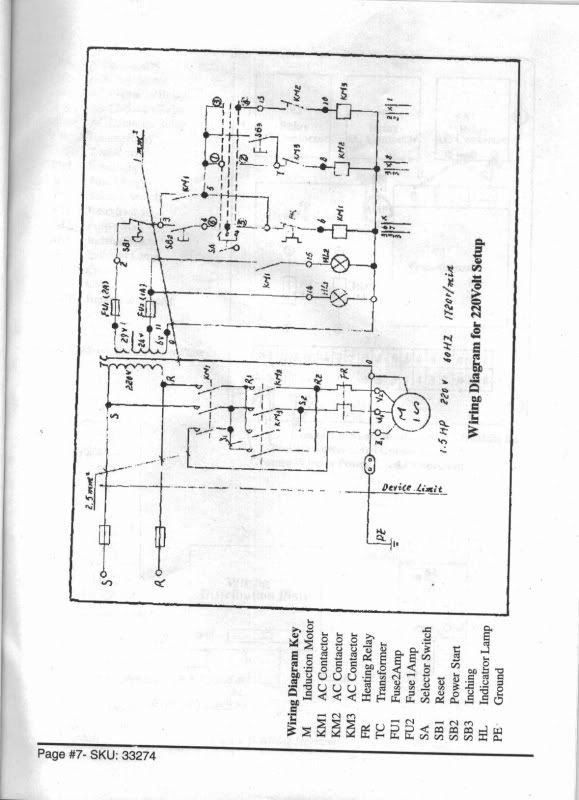

The lathe has a 220V single phase 1.5hp motor. I have the manual and will try to get the schematic scanned so I can post it. it shows 3 AC relay contactors, a transformer, heating relay, 2 fuses, the selector switch, and the safety switch and inching switch and power bulb and the motor.

I believe I fried the motor or possibly a capacitor and, also have an issue where power is being fed to the motor even when the selector switch is off. I am not sure what is up with the occasional no spin when the switch was on. The motor would hum so I was thinking one of the legs of power was not getting to the windings but that is just a guess.

So, anyone who knows 220 motors I would appreciate any info you could share.Thanks Chris 720 206 4034

I turned on the switch and the lathe started to spin up but slower than normal. I decided to shut it off as something is definately wrong but before I could get my hand to the switch there was a small explosion in/around the motor and a puff of black smoke. I slapped the kill button and unplugged the lathe.

For around the last month every once in a while I would hit the on switch and the lathe would either not spin or would take a half a second and then start spinning. When it would not start I would here a buzz but louder than it was tonight with the switch off. If I grabbed the chuck and moved it at all it would spin right up to speed like normal. It only happened a couple times but it never did this before. I have another identical lathe on the same breaker and it always starts correctly so I believe the power in is not the issue.

The lathe has a 220V single phase 1.5hp motor. I have the manual and will try to get the schematic scanned so I can post it. it shows 3 AC relay contactors, a transformer, heating relay, 2 fuses, the selector switch, and the safety switch and inching switch and power bulb and the motor.

I believe I fried the motor or possibly a capacitor and, also have an issue where power is being fed to the motor even when the selector switch is off. I am not sure what is up with the occasional no spin when the switch was on. The motor would hum so I was thinking one of the legs of power was not getting to the windings but that is just a guess.

So, anyone who knows 220 motors I would appreciate any info you could share.Thanks Chris 720 206 4034