You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VCarve pro 11 for tapering

- Thread starter icbm

- Start date

I recently purchased an I2R 8 cnc. I've looked at Kelly's cue cut software but I was wondering if anyone here has used VCarve pro 11 to make tapers? Thank you for any help

I use Aspire, like an upgraded version of VCarve. Stick to Kelly’s program. Never attempted to make tapers on Aspire, it beats its purpose. CueCut does everything you need except for creating gcode to cut points.

Unless you are trying to use arcs, tapers can be very easily written up with just simple gcode.

N2 G00 X0. Y-.5

N4 G01 Y0. F20.

N5 X6.5 Y-.003

N6 X12.5 Y-.015

N7 X16.5 Y-.03

N8 X20.5 Y-.069

N9 X24.5 Y-.113

N10 X30.15 Y-.197

N11 G00 Y-.5

N12 X0.

M30

N2 G00 X0. Y-.5

N4 G01 Y0. F20.

N5 X6.5 Y-.003

N6 X12.5 Y-.015

N7 X16.5 Y-.03

N8 X20.5 Y-.069

N9 X24.5 Y-.113

N10 X30.15 Y-.197

N11 G00 Y-.5

N12 X0.

M30

Last edited:

I don't see why you can't.

Pretend like you're milling 1" by 29" rectangle from one side for shafts.

Kelly's would be a lot easier but it doesn't do arcs it it matters.

Pretend like you're milling 1" by 29" rectangle from one side for shafts.

Kelly's would be a lot easier but it doesn't do arcs it it matters.

In my CNC router the Y is the long bed.Unless you are trying to use arcs, tapers can be very easily written up with just simple gcode.

N2 G00 X0. Y-.5

N4 G01 Y0. F20.

N5 X6.5 Y-.003

N6 X12.5 Y-.015

N7 X16.5 Y-.03

N8 X20.5 Y-.069

N9 X24.5 Y-.113

N10 X30.15 Y-.197

N11 G00 Y-.5

N12 X0.

M30

I see a crash..

You can create tapers using VCarve, GCODE and CueCut.

My preference is CueCut. It's simple, intuitive and hard(er) to screw things up. It's a one trick pony that performs it's trick reliably well.

Unless your spinner is dead nuts in line with your long axis, your measured results will differ from your selected taper values. CueCut is the easiest of the 3 methods to dial in the alignment error of your spinner. You can error compensate with VCarve and GCODE. It's just more work.

I get it. You bought VCarve. It WILL generate taper code just fine. Do you really need to buy CueCut to do the what VCarve or GCODE will do? No, you don't. If you buy CueCut, will you regret it? I don't think you will.

My preference is CueCut. It's simple, intuitive and hard(er) to screw things up. It's a one trick pony that performs it's trick reliably well.

Unless your spinner is dead nuts in line with your long axis, your measured results will differ from your selected taper values. CueCut is the easiest of the 3 methods to dial in the alignment error of your spinner. You can error compensate with VCarve and GCODE. It's just more work.

I get it. You bought VCarve. It WILL generate taper code just fine. Do you really need to buy CueCut to do the what VCarve or GCODE will do? No, you don't. If you buy CueCut, will you regret it? I don't think you will.

icbm

Registered

Thank you brother. My new concern is the headstock on the I2R 8 4th axis is stepper driven so I don't know if it will spin the same way a custom built or like a Taig 4th axis will.You can create tapers using VCarve, GCODE and CueCut.

My preference is CueCut. It's simple, intuitive and hard(er) to screw things up. It's a one trick pony that performs it's trick reliably well.

Unless your spinner is dead nuts in line with your long axis, your measured results will differ from your selected taper values. CueCut is the easiest of the 3 methods to dial in the alignment error of your spinner. You can error compensate with VCarve and GCODE. It's just more work.

I get it. You bought VCarve. It WILL generate taper code just fine. Do you really need to buy CueCut to do the what VCarve or GCODE will do? No, you don't. If you buy CueCut, will you regret it? I don't think you will.

Thank you brother. My new concern is the headstock on the I2R 8 4th axis is stepper driven so I don't know if it will spin the same way a custom built or like a Taig 4th axis will.

It can but you need a second station for tapering in the CNC with a taig lathe bed, tailstock and motor.

Tony,I use Aspire, like an upgraded version of VCarve. Stick to Kelly’s program. Never attempted to make tapers on Aspire, it beats its purpose. CueCut does everything you need except for creating gcode to cut points.

I think with just a little bit of thinking CueCut will generate the code to cut points also. I use Bobcad to do it, but CueCut could generate the path, just not the automatic indexing.

Alan

Tony, I think with just a little bit of thinking CueCut will generate the code to cut points also. I use Bobcad to do it, but CutCut could generate the path, just not the automatic indexing.

Alan

I actually told Kelly about it, I hope he can make it happen someday.

I do have a CNC program that generates my points automatically though.

Agreed, it would be a nice addition to the program.I actually told Kelly about it, I hope he can make it happen someday.

I do have a CNC program that generates my points automatically though.

Thank you brother. My new concern is the headstock on the I2R 8 4th axis is stepper driven so I don't know if it will spin the same way a custom built or like a Taig 4th axis will.

This is something to verify. CueCut is a 3 axis program. The first question is can your stepper/4th axis fixture spin fast enough to turn stock the way cuemakers turn stock? (VS a laboriously slow carving of a baseball bat I have seen a video of.) If so, and you are using Mach, you can set the 4th axis to act as a spindle and put it into continuous spin mode with a spindle on and spindle speed commands that are options in CueCut. Some of the Unique CNC machines (and a few others) were set up this way. I don't use Mach so I don't know the specific steps to do this, but a lot of CueCut folks do.

If the above isn't feasible for your machine, do you have the real estate? A spinner independent of your 4th axis fixture is a wonderful thing when you have a cue in the 4th axis fixture (inlay purposes kind of thing) and you need to turn something.

Regarding cutting points with CueCut, several folks have done this. It takes some thought and a little bit of ingenuity, but cutting points is just tapering from one diameter to another with a Vee bit rather than straight bit. A good point cutting program would have a few minor details different, but mostly the same. But since the program was not designed for cutting points, it's too difficult and time consuming to hold hands so users are on their own here.

I second the cue cut. Kelly has put Together an extremely well done and well thought out program. Sure you can do it 10 other ways but none are a simple or as intuitive. I think every cue maker out there should pony up the couple bucks if nothing else just to show the support to him so he can continues to upgrade the software. also I have a taper machine with a spindle driving the turn station. It is a cheap nema 23 with 4:1 belt reduction and I can run it about 330 rpm for turning without losing too much torque. steppers lose torque as rpm increases and this varies with the motor. Also mine is parallel port driven and you can hit the ceiling of pulses per second to reach top speed So keep that in mind if you introduce belt reduction and micro stepping

icbm

Registered

Thank you for that. I had been wondering about the feasibility of adding a spinner.It can but you need a second station for tapering in the CNC with a taig lathe bed, tailstock and motor.

What I did was this....Unfortunately the headstock on the 4th axis is driven by a stepper motor

I added a quad pole double throw switch and a small step generator (~$30 total). I wired it up so I can switch between using it as a spinner or controlling it via the 4th axis controller by simply flipping the switch. Prior to that I was swapping out the stepper headstock with a simple taig style motor and headstock depending on if I was tapering or doing inlays, rings, etc. It wasn't too much trouble but a little time consuming to get everything dialed in after every swap.

Now I just flip the switch and I don't have to touch the setup. The stepper generator is more than capable to generate the speeds I need for tapering.

Got the idea for the stepper generator from Dave38 in this post: https://forums.azbilliards.com/threads/dc-motor-recomendation.524087/page-2#post-6849180

I'll try to get a couple pictures after work tonight.

Oh and before I forget, Kelly's cue cut is really nice... so easy to experiment with different tapers without having to spend so much time hand programming. As a plus, the visual representation of the tapers make it easy to compare one taper to another without having to resort to charting them in a spreadsheet or drawing them out in CAD. It was well worth it for me!

Last edited:

icbm

Registered

Thank you brother. I'll look forward to your postWhat I did was this....

I added a quad pole double throw switch and a small step generator (~$30 total). I wired it up so I can switch between using it as a spinner or controlling it via the 4th axis controller by simply flipping the switch. Prior to that I was swapping out the stepper headstock with a simple taig style motor and headstock depending on if I was tapering or doing inlays, rings, etc. It wasn't too much trouble but a little time consuming to get everything dialed in after every swap.

Now I just flip the switch and I don't have to touch the setup. The stepper generator is more than capable to generate the speeds I need for tapering.

Got the idea for the stepper generator from Dave38 in this post: https://forums.azbilliards.com/threads/dc-motor-recomendation.524087/page-2#post-6849180

I'll try to get a couple pictures after work tonight.

Oh and before I forget, Kelly's cue cut is really nice... so easy to experiment with different tapers without having to spend so much time hand programming. As a plus, the visual representation of the tapers make it easy to compare one taper to another without having to resort to charting them in a spreadsheet or drawing them out in CAD. It was well worth it for me!

Don't know if these will help or not but this is my setup.

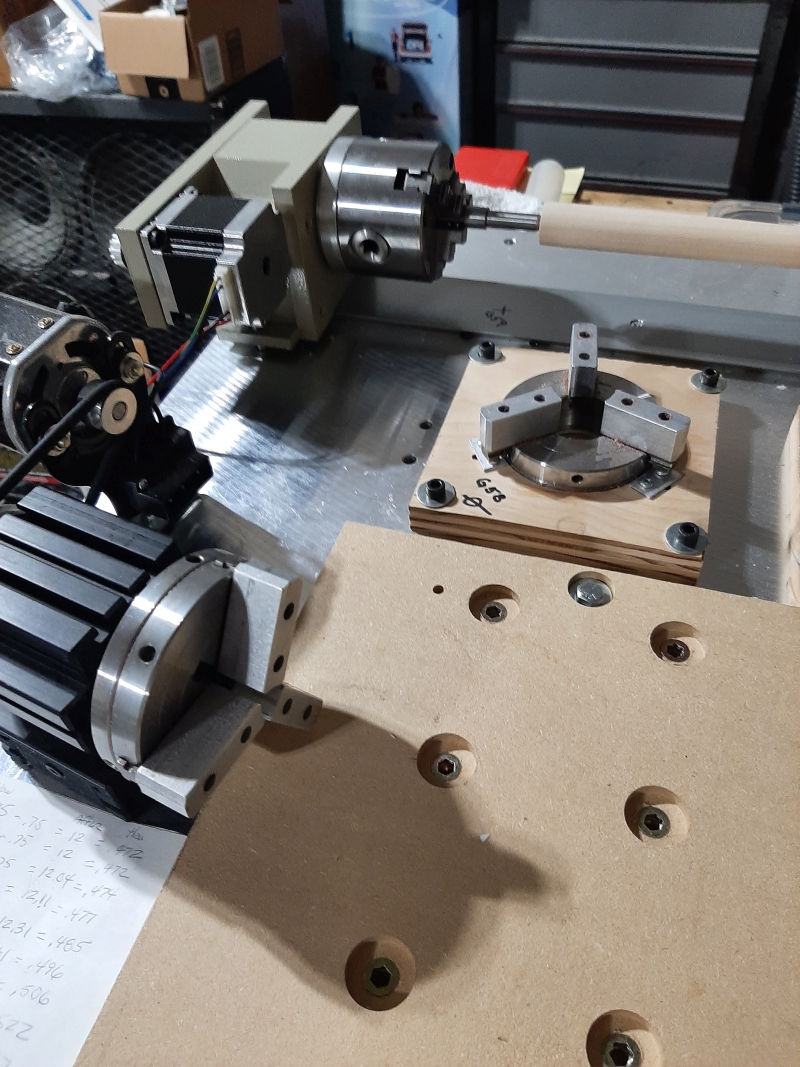

Picture 1. I was manually swapping these two headstocks on to the lathe rail depending on if I was tapering or doing inlays, billets, etc.

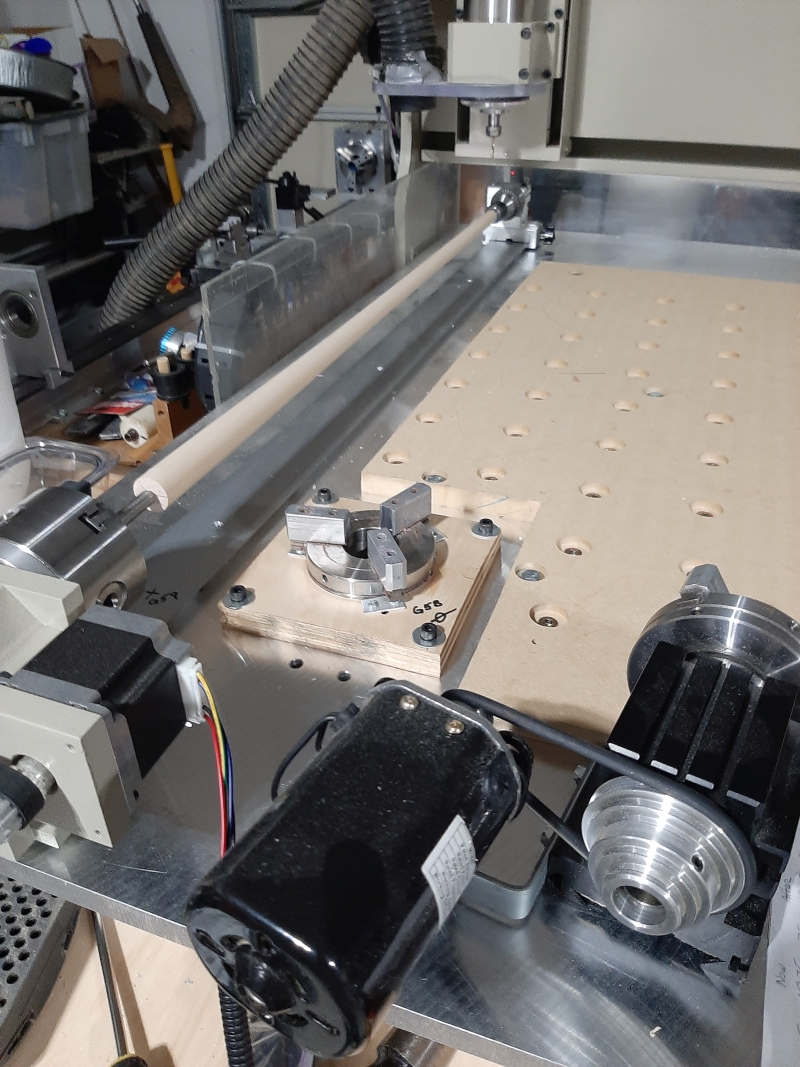

Picture 2. This shows how I mounted the lathe rail and how I do my tapers.

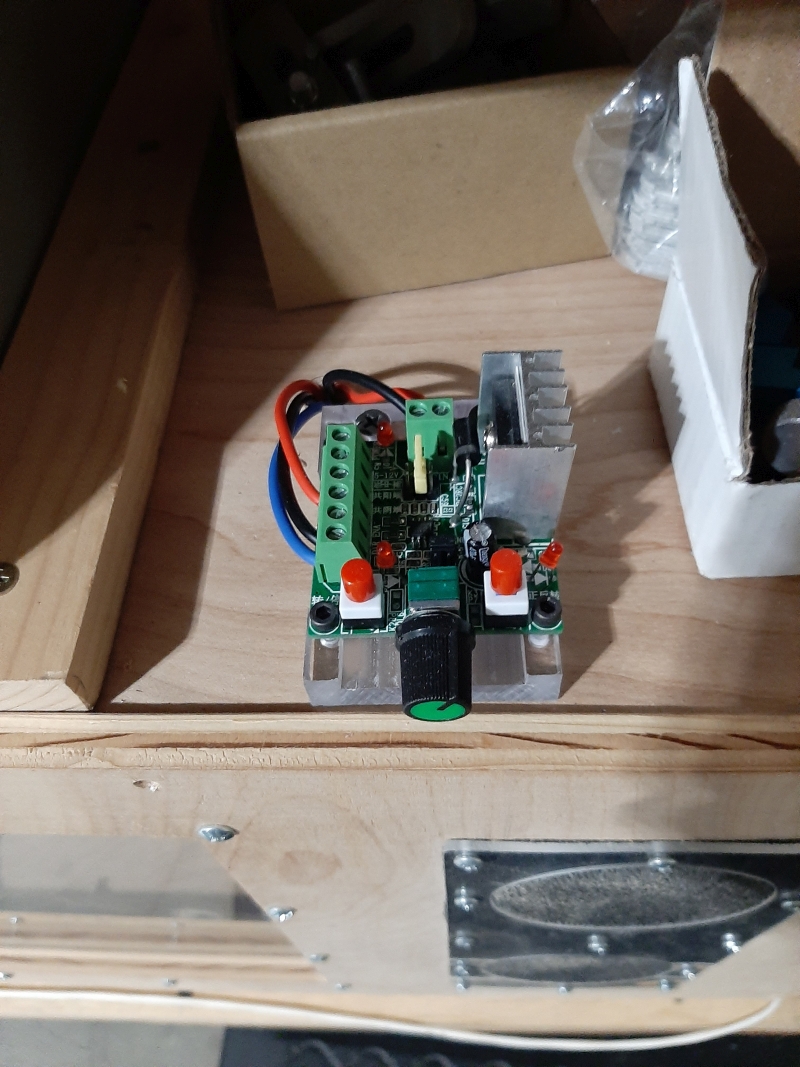

Picture 3. This shows the step generator... works real well.

Picture 4. This shows the switches, one supplies power to the step generator, the other switches between control via CNC controller (full 4th axis CNC control) or step generator (spinner only). It's actually a three position switch, both off in the center.

I know these pictures don't tell the whole story so if you have any questions or if you decide to go this direction and need any help don't hesitate to ask. Good luck however you decide to proceed!

Picture 1. I was manually swapping these two headstocks on to the lathe rail depending on if I was tapering or doing inlays, billets, etc.

Picture 2. This shows how I mounted the lathe rail and how I do my tapers.

Picture 3. This shows the step generator... works real well.

Picture 4. This shows the switches, one supplies power to the step generator, the other switches between control via CNC controller (full 4th axis CNC control) or step generator (spinner only). It's actually a three position switch, both off in the center.

I know these pictures don't tell the whole story so if you have any questions or if you decide to go this direction and need any help don't hesitate to ask. Good luck however you decide to proceed!

To be clear, when I referred to CueCut as a 'one trick pony', I meant it as a complement. It is an application specific solution focused on one primary purpose, cutting stock from simple dowels to compound tapers with a very well thought out, easy to use interface that is targeted specifically to the cue maker. Rereading my own remark sounded snarky and it was not intended to be.This is something to verify. CueCut is a 3 axis program. The first question is can your stepper/4th axis fixture spin fast enough to turn stock the way cuemakers turn stock? (VS a laboriously slow carving of a baseball bat I have seen a video of.) If so, and you are using Mach, you can set the 4th axis to act as a spindle and put it into continuous spin mode with a spindle on and spindle speed commands that are options in CueCut. Some of the Unique CNC machines (and a few others) were set up this way. I don't use Mach so I don't know the specific steps to do this, but a lot of CueCut folks do.

If the above isn't feasible for your machine, do you have the real estate? A spinner independent of your 4th axis fixture is a wonderful thing when you have a cue in the 4th axis fixture (inlay purposes kind of thing) and you need to turn something.

Regarding cutting points with CueCut, several folks have done this. It takes some thought and a little bit of ingenuity, but cutting points is just tapering from one diameter to another with a Vee bit rather than straight bit. A good point cutting program would have a few minor details different, but mostly the same. But since the program was not designed for cutting points, it's too difficult and time consuming to hold hands so users are on their own here.