Hello,

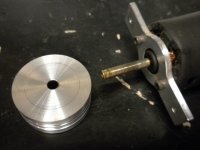

Picked one of these up cheap as is. The motor runs smooth on it but the pulley

on the motor does not fit snug on the shaft, it seems like it picks up speed with friction if this makes any sense? Does this sound normal or should the pulley be tight on the motor shaft? I would think it should be tight but I have been wrong before.

Any info would be greatly appreciated.

Picked one of these up cheap as is. The motor runs smooth on it but the pulley

on the motor does not fit snug on the shaft, it seems like it picks up speed with friction if this makes any sense? Does this sound normal or should the pulley be tight on the motor shaft? I would think it should be tight but I have been wrong before.

Any info would be greatly appreciated.