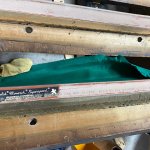

I have recently purchased a 1913 - 1916 Brunswick Kling. It is a 6 leg, Circassian Walnut / Rosewood Rail, 1.5” slate with ball return. I have begun restoration but am not a pro, but very handy and capable. My parents were antique dealers so I understand restoration and not to overdo it and leave some “patina“. i have included some puctures. One thing i am particularly interested in is the serial numbering etc. It is numbered 5840 everywhere and 40 written on many parts. Is there any way to chase these numbers down to understand what they may lead to? The ball return parts are stamped with a different number. I have begun stripping it and lightly sanding and trying to figure our stains, if any, types of clearcoats, etc. generally anything to keep it authentic. Should i just use an oil on everything below the rail and bolt cover? Looking for comments from folks who know.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1916ish Brunswick Kling 6 Leg Restoration Advice

- Thread starter OC Skip

- Start date

Nice!

The numbers were to keep all the same parts with the same table.

However, the complete serial number may be able to be referenced to the actual origins and purchaser if there is a database (I don't know specifically)

It is rare, exceedingly rare, that stains were used on these or any woodwork except cruder stuff and some oak, back in that time period. Even the oak was more likely fumed (with real ammonia) than stained. As sometimes was mahogany.

It was not rare to tint, with dyes or what today would be called toners.

Often, a lot of the unifying color was in the finish, and not heavy at the time it was applied though most has darkened considerably since.

Almost everything high quality in that era was finished with shellac.

Sometimes varnish, but varnish takes too long at the factory, and was more labor intensive, for an inferior look (lack of clarity)

In those days, people understood polish (shellac) and there were services that would re-polish high end stuff when necessary, by appointment. It was just part of the maintenance, and relatively quick & easy.

If the table has never been re-finished, you can test with denatured alcohol. With age, even shellac can become quite resistant, but it may soften. If the shellac was also polished with oil, very faintly, and only occasionally, it will be very resistant to alcohol, and even to water. Varnish will be essentially impervious.

You should work up a sample board.

They did not use oil quite the way we have since the 60's danish oil fad (which on good danish furniture was really conversion varnish) made it popular.

Some methods of polish from that pre-ww1 era included oil, let dry and steel wooled, then polished with shellac. OTOH it was more often started with extremely thin shellac (like 1/2lb cut or less - the more alcohol the better) for first saturation coats, then a traditional ("french") polish worked up, and then after a week or so drying, a good rub down with oil leaving none on the surface.

IME, the thin coat saturation with shellac is the most fool-proof method. It will always be the most clear, and you can stop at any time. It does a good job of consolidating veneer and avoiding blotchiness. In early days it can be washed off with more alcohol; though you have to be careful over dye tints. You may need a range of flakes, from super blonde or platina, right down through seedlac to get the tones right as the finish develops. Always use fresh mixed, in bottles dated by you, throw them out at 6 months. Never used pre-mixed from a can. Generally speaking, only use de-waxed. Shelf life is shorter, but applied product is more durable. There's a ton of wax in non-dewaxed shellac & in canned shellac, and it does no good.

If you want to use modern finishes, i'm not very conversant.

I'm not an expert at all on pool tables, restoring in the billiards field is new to me & only for personal interest. OTOH I have been considered an expert for some forms of wood repair and refinishing by several national museums & government entities. (provide materials & participate in some finer restoration/repair projects at the facilities themselves, though degreed technical experts above me provide the approvals) What everyone knows is there's always a surprise, and more to learn.

PS, don't try to use polish (shellac) like varnish. Keep it thin, but just thick enough.

there's a learning curve to working with ancient natural materials.

This is my wife's 1926 project table. Currently on hold as renovations gradually occur to the room.

The numbers were to keep all the same parts with the same table.

However, the complete serial number may be able to be referenced to the actual origins and purchaser if there is a database (I don't know specifically)

I have begun stripping it and lightly sanding and trying to figure our stains, if any,

It is rare, exceedingly rare, that stains were used on these or any woodwork except cruder stuff and some oak, back in that time period. Even the oak was more likely fumed (with real ammonia) than stained. As sometimes was mahogany.

It was not rare to tint, with dyes or what today would be called toners.

Often, a lot of the unifying color was in the finish, and not heavy at the time it was applied though most has darkened considerably since.

types of clearcoats, etc. generally anything to keep it authentic.

Almost everything high quality in that era was finished with shellac.

Sometimes varnish, but varnish takes too long at the factory, and was more labor intensive, for an inferior look (lack of clarity)

In those days, people understood polish (shellac) and there were services that would re-polish high end stuff when necessary, by appointment. It was just part of the maintenance, and relatively quick & easy.

If the table has never been re-finished, you can test with denatured alcohol. With age, even shellac can become quite resistant, but it may soften. If the shellac was also polished with oil, very faintly, and only occasionally, it will be very resistant to alcohol, and even to water. Varnish will be essentially impervious.

Should i just use an oil on everything below the rail and bolt cover? Looking for comments from folks who know.

You should work up a sample board.

They did not use oil quite the way we have since the 60's danish oil fad (which on good danish furniture was really conversion varnish) made it popular.

Some methods of polish from that pre-ww1 era included oil, let dry and steel wooled, then polished with shellac. OTOH it was more often started with extremely thin shellac (like 1/2lb cut or less - the more alcohol the better) for first saturation coats, then a traditional ("french") polish worked up, and then after a week or so drying, a good rub down with oil leaving none on the surface.

IME, the thin coat saturation with shellac is the most fool-proof method. It will always be the most clear, and you can stop at any time. It does a good job of consolidating veneer and avoiding blotchiness. In early days it can be washed off with more alcohol; though you have to be careful over dye tints. You may need a range of flakes, from super blonde or platina, right down through seedlac to get the tones right as the finish develops. Always use fresh mixed, in bottles dated by you, throw them out at 6 months. Never used pre-mixed from a can. Generally speaking, only use de-waxed. Shelf life is shorter, but applied product is more durable. There's a ton of wax in non-dewaxed shellac & in canned shellac, and it does no good.

If you want to use modern finishes, i'm not very conversant.

I'm not an expert at all on pool tables, restoring in the billiards field is new to me & only for personal interest. OTOH I have been considered an expert for some forms of wood repair and refinishing by several national museums & government entities. (provide materials & participate in some finer restoration/repair projects at the facilities themselves, though degreed technical experts above me provide the approvals) What everyone knows is there's always a surprise, and more to learn.

PS, don't try to use polish (shellac) like varnish. Keep it thin, but just thick enough.

there's a learning curve to working with ancient natural materials.

This is my wife's 1926 project table. Currently on hold as renovations gradually occur to the room.

Library resource for pool table repair

NYS has a mandate for "maker spaces" in libraries. I never used the local facility, but know the guy who runs it, and have often donated small amounts of plywood & materials. He has been over to the shop to use my larger machines to break down larger pieces of material so they will fit on the...

forums.azbilliards.com

Last edited:

Sounds like Ssonerai knows a lot of wood working history. A very good friend of mine would enjoy having a conversation with him or her. They'd likely learn from ea other a thing or two.

If you want to get as close as possible to what Brunswick did search Clay Center Kansas and Brunswick. Or Billiard restoration. There's a couple of businesses in town. One gentleman is or was Brunswick's Historian.

He knows more than Brunswick knows/knew about Brunswick. Nowell?? is the last name?

If you want to get as close as possible to what Brunswick did search Clay Center Kansas and Brunswick. Or Billiard restoration. There's a couple of businesses in town. One gentleman is or was Brunswick's Historian.

He knows more than Brunswick knows/knew about Brunswick. Nowell?? is the last name?