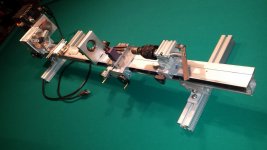

48 inch taig based cue lathe with 36 inch gear rack. Lathe bed is mounted on super strong 1.5 inch 8020 aluminum stock. Unit is light and highly portable.

Headstock was made by Bassel at Custom Cue Lathes with a 1.4 inch spindle and 3 jaw chuck so it can hold a pool cue but or wood stock for cue building. It is powered with a Penn State 1/2 horse power variable speed motor. These are very powerful and run smoothly and quietly from low speed to high with a turn of a dial. I added a dpdt switch at the right end of the control box which switches the rotation of the lathe from forward to off or to reverse. When using the lathe your left hand rests atop the controller and your thumb is conveniently resting on the 3 way switch. When running the lathe is very stable at all speeds. This is much better than any board mounted lathe.

Package inculdes:

2 Tommy bars for adjusting the lathe chuck

-3/8-10 male/female driver

-5/16-14 male/female driver pin

-5/16 -18 maintenance driver

-Uniloc quick release maintenance driver (from Lucasi cue joint) fits predator and Lucas QR

3 shaft collets for holding shaft when doing tip or ferrule work

Steady rest with 30mm (1.17 inch) circular bearing

Comes with the following collets:

0.825 shaft joint

O.863 butt joint

0.925 butt forearm

Its easy to make all the collets you need with the lathe and a little derlin.

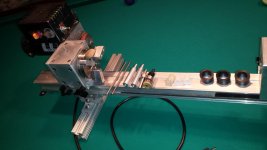

Taig carriage and toolpost with the following lathe bits

-Right hand cut, the most commonly used bit to turn down material from the right hand side

-Cutoff, cuts across material

-Boring, to bore out a hole in the end of the workpiece

Taig rear drilling tailstock. This tailstock has a lever to allow drilling about 2 inches in depth. To droll further just advance the tailstock down the bed. It has a 60 degree dead center at the end of the shaft which is used to turn stock if you are cutting sonething on center. A Jacobs 1/2 inch capacity keyless chuck, just turn the chuck to close jaws. Comes with a concave live center used to hold a shaft in place that already has a tip on it when doing shaft maintenance.

I added 3 full splice cues for conversions so you have some projects for the lathe. 1 old tru balance and 2 old AMF cues. I'd cut them to 34 inches end pack them with the lathe.

Overall this is a super reliable unit. Indestructible really. You can do any maintenance or repair with this unit. Put on tips or ferrules, clean and sand shafts, put on wraps, repair buttcaps, cue joints, shaft inserts, replace joint pins...really anything. I have made conversion cues with this. You can offset the tailstock by loosening the Allen bolt mount and can cut straight tapers to make a cue butt. All the information to do these tasks is readily available.

This lathe is equivalent to a mid level lathe that is going to cost $1600 plus tax, plus shipping. You be out over $1800 in total buying new.

I'm offering this setup for THE FINAL PRICE DROP TO $950 including insured delivery. You may make payment by paypal.

Any questions or offers please pm me.

Escrow can be arranged.

I can bring the lathe to Turning Stone Classic 1/7 to 1/10 and it can be bought for $900.

Headstock was made by Bassel at Custom Cue Lathes with a 1.4 inch spindle and 3 jaw chuck so it can hold a pool cue but or wood stock for cue building. It is powered with a Penn State 1/2 horse power variable speed motor. These are very powerful and run smoothly and quietly from low speed to high with a turn of a dial. I added a dpdt switch at the right end of the control box which switches the rotation of the lathe from forward to off or to reverse. When using the lathe your left hand rests atop the controller and your thumb is conveniently resting on the 3 way switch. When running the lathe is very stable at all speeds. This is much better than any board mounted lathe.

Package inculdes:

2 Tommy bars for adjusting the lathe chuck

-3/8-10 male/female driver

-5/16-14 male/female driver pin

-5/16 -18 maintenance driver

-Uniloc quick release maintenance driver (from Lucasi cue joint) fits predator and Lucas QR

3 shaft collets for holding shaft when doing tip or ferrule work

Steady rest with 30mm (1.17 inch) circular bearing

Comes with the following collets:

0.825 shaft joint

O.863 butt joint

0.925 butt forearm

Its easy to make all the collets you need with the lathe and a little derlin.

Taig carriage and toolpost with the following lathe bits

-Right hand cut, the most commonly used bit to turn down material from the right hand side

-Cutoff, cuts across material

-Boring, to bore out a hole in the end of the workpiece

Taig rear drilling tailstock. This tailstock has a lever to allow drilling about 2 inches in depth. To droll further just advance the tailstock down the bed. It has a 60 degree dead center at the end of the shaft which is used to turn stock if you are cutting sonething on center. A Jacobs 1/2 inch capacity keyless chuck, just turn the chuck to close jaws. Comes with a concave live center used to hold a shaft in place that already has a tip on it when doing shaft maintenance.

I added 3 full splice cues for conversions so you have some projects for the lathe. 1 old tru balance and 2 old AMF cues. I'd cut them to 34 inches end pack them with the lathe.

Overall this is a super reliable unit. Indestructible really. You can do any maintenance or repair with this unit. Put on tips or ferrules, clean and sand shafts, put on wraps, repair buttcaps, cue joints, shaft inserts, replace joint pins...really anything. I have made conversion cues with this. You can offset the tailstock by loosening the Allen bolt mount and can cut straight tapers to make a cue butt. All the information to do these tasks is readily available.

This lathe is equivalent to a mid level lathe that is going to cost $1600 plus tax, plus shipping. You be out over $1800 in total buying new.

I'm offering this setup for THE FINAL PRICE DROP TO $950 including insured delivery. You may make payment by paypal.

Any questions or offers please pm me.

Escrow can be arranged.

I can bring the lathe to Turning Stone Classic 1/7 to 1/10 and it can be bought for $900.

Attachments

Last edited: