Hi all,

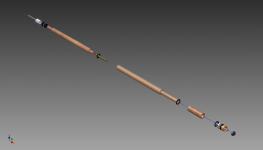

Just wanted to show you my "Summer Project" and want to hear what experienced builders think about it. This will be my first cue build from scratch by my own (hopefully successfull).

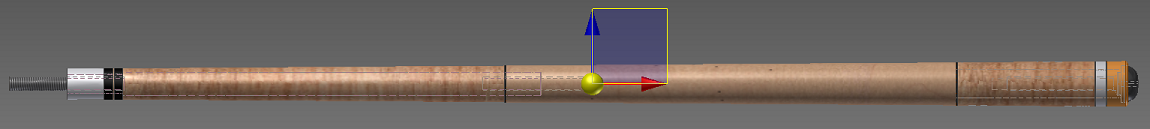

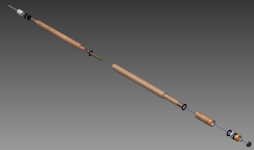

Forearm and Buttsleeve will be Golden Madrone Burl. Forearm cored with PurpleHeart. Handle will be Curly Maple. All white is Ivory. SS radial pin. Aluminium Weight Bold 3/8-16. A-Joint connection screw is SS. All black is phenolic/double blacl linen.

Butt weight is 415g, length is 74cm. Balance point is 36.6cm from the beginning of the joint and 37.4 from the end of the butt cap.

The pics don't show the real beauty of the woods because i don't have the correct textures available.

Do you see any construction mistakes?

All comments welcome

Thanks

Baba

Just wanted to show you my "Summer Project" and want to hear what experienced builders think about it. This will be my first cue build from scratch by my own (hopefully successfull).

Forearm and Buttsleeve will be Golden Madrone Burl. Forearm cored with PurpleHeart. Handle will be Curly Maple. All white is Ivory. SS radial pin. Aluminium Weight Bold 3/8-16. A-Joint connection screw is SS. All black is phenolic/double blacl linen.

Butt weight is 415g, length is 74cm. Balance point is 36.6cm from the beginning of the joint and 37.4 from the end of the butt cap.

The pics don't show the real beauty of the woods because i don't have the correct textures available.

Do you see any construction mistakes?

All comments welcome

Thanks

Baba