i have an old schon, id say late 80s early 90s, schon is not on either of the shafts. Ive bought 2 different sets of joint protectors, and both would work but it was supertight, feels almost like its rethreading the protector. I know schon used several different versions of the 5/16, how do i measure it? I want to get another shaft for it but im scared it will fit like everything else, too tight. Any idea which screw this one is once i measure it? was there more than just 2 or 3types?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

question about the 5/16 14 thread?

- Thread starter scottycoyote

- Start date

If you have a vernier just measure the pin.

There were only two. One .310 and .302. Hope this helps.

There were only two. One .310 and .302. Hope this helps.

mike.....what am i supposed to be measuring?

I took my calipers and put them inside the screws and outside them and im not coming up with numbers anything close. Im guessing i have the least popular one because nothing i buy for 5/16 14 seems to fit mine right.

I took my calipers and put them inside the screws and outside them and im not coming up with numbers anything close. Im guessing i have the least popular one because nothing i buy for 5/16 14 seems to fit mine right.

scottycoyote said:mike.....what am i supposed to be measuring?

I took my calipers and put them inside the screws and outside them and im not coming up with numbers anything close. Im guessing i have the least popular one because nothing i buy for 5/16 14 seems to fit mine right.

Measure the outside of the pin. What did your measurement say.

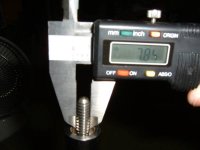

i dont seem to be coming up with anything close to that mike......it could be im just retarded...and we probably shouldnt rule that out lol. Heres some pics of the different ways i measured, in the pictures they arent precise measurements because its hard to hold it and shoot the pic but you get the idea.

Attachments

It looks like the Schon was reworked. Picture one is the way I was talking about. Is it still going into brass inserts in the shafts or wood. It also looks like it is a flat faced joint now. If you have two shafts for it, send me one.

no neither one is flat faced, they are both piloted (or whatever you call it where the brass insert fits down into the joint). I actually love the way the cue fits together and feels, it tightens up and then the last turn or so is quite a bit tighter than the rest of the length. Although i would be a little irked ti find out this cue has been reworked. Both shafts have the silver ring but neither says schon on it, so i place the cue late 80s early 90s, unless these arent the original shafts either.

Attachments

That's the original joint, This picture is better than the others.

Vonn31 said:I'm a machinist. It sure looks like 5/16-14 to me but I can't tell without some thread gages. The tightness is from the pilot rubbing as you screw it together. Have someone turn .010 off the diameter of the pilot on the shaft. That ought to fix it.

noooo........the problem isnt the shafts i have are too tight, theyre perfect. The problem is, I have bought 2 sets of joint protectors in 5/16 14, and its all i can do to screw them onto the joint or into the shafts. I have to do them with alot of force, i mean like trying to open a jar almost, that kind of tight, and it feels like its tearing up the threads of the protector.

When i thread my shaft onto my cue.....it fits on nice, i can tighten it on with my thumb, then at the very end it tightens up (which is the pilot now i understand). And the joint protectors that came with the cue.....i can put then either on the shaft or the butt, and spin them on. Thats what makes me think i have a different 5/16 14. So before i buy another shaft, z or tiger, i want to make sure it will work, or i need to buy the blank and get someone to make it. I just think my 5/16 is different somehow becuase none of the thread protectors work on it. Thats why i was asking for measurements or opinions

scottycoyote said:i dont seem to be coming up with anything close to that mike......it could be im just retarded...and we probably shouldnt rule that out lol. Heres some pics of the different ways i measured, in the pictures they arent precise measurements because its hard to hold it and shoot the pic but you get the idea.

thats really funny... you might want to switch your calipers to standard not metric?

Vonn31 said:I'm a machinist. It sure looks like 5/16-14 to me but I can't tell without some thread gages. The tightness is from the pilot rubbing as you screw it together. Have someone turn .010 off the diameter of the pilot on the shaft. That ought to fix it.

boy its a good thing your a machinist.... i would hate for anyone else to tell someone to cut on a perfectly good cue.

IMO If the fit is tight on the pin, It's probably the larger diameter pin of the 2, or the joint protector was bored smaller then standard before tapping, and fits the other size. That is assuming the thread is not modified, It is of the same pattern,and depth. If you know it's the same thread ,the protector screws on the pin kind of loosely, and feels like it's crossthreading then the pin diameter is probably smaller.

I don't know the specific diameters or thread patterns They used, but Mike seems very knowledgeble and well equipted for them, and has every tap known to man so his advice should be from a good source, and worth taking in.

so his advice should be from a good source, and worth taking in.

Pretty sure The pilots should be snug in this case, atleast that's the way I prefer to do them, and believe I'm safe in saying some others do, so they snug up right at the bottom turn. I imagine that was schon's intention for using them, as well as centering & alignment. looks like a good fit to me, altough recomend cleaning them & the threads instead of trimming should they pose a problem. I would only trim in extreme cases. If both shafts were to have a problem, then look at the bore in the joint, or bent pin.

I know they do appear to be rubbing pretty hard from the marks, but from what I have seen that is normal over time with this type of joint. If It's rubbing smoothly & evenly all the way around then that's even better, because it's centering properly IMO. I like the snug fit in a cue myself. Greg

I don't know the specific diameters or thread patterns They used, but Mike seems very knowledgeble and well equipted for them, and has every tap known to man

Pretty sure The pilots should be snug in this case, atleast that's the way I prefer to do them, and believe I'm safe in saying some others do, so they snug up right at the bottom turn. I imagine that was schon's intention for using them, as well as centering & alignment. looks like a good fit to me, altough recomend cleaning them & the threads instead of trimming should they pose a problem. I would only trim in extreme cases. If both shafts were to have a problem, then look at the bore in the joint, or bent pin.

I know they do appear to be rubbing pretty hard from the marks, but from what I have seen that is normal over time with this type of joint. If It's rubbing smoothly & evenly all the way around then that's even better, because it's centering properly IMO. I like the snug fit in a cue myself. Greg

I tend to think the pin in your Schon is the .302X14 which would make the standard joint protectors for the shafts screw tightly. If you can't adjust it yourself the option is still there to send me the protectors and one shaft.

Michael Webb said:I tend to think the pin in your Schon is the .302X14 which would make the standard joint protectors for the shafts screw tightly. If you can't adjust it yourself the option is still there to send me the protectors and one shaft.

so once i figure out which shaft i want.....i could just order a blank and then send it to you with a protector and one of my shafts? whats something like that cost?

scottycoyote said:so once i figure out which shaft i want.....i could just order a blank and then send it to you with a protector and one of my shafts? whats something like that cost?

I have no idea what your talking about as far as other shafts. I was talking about fitting the joint protectors.

good lord is nobody actually reading my posts????? lol

the whole point of this whole thing, as ive said a few times, is I want TO BUY A NEW SHAFT FOR MY SCHON AND I WANT TO MAKE SURE IT WILL FIT AND THIS WHOLE PROBLEM WITH THE JOINT PROTECTORS MAKES ME THINK I DONT HAVE A STANDARD SIZE 5/16 14 THREAD.

I dont want to just order a z shaft or a tiger shaft and then have to screw it on with a pair of pliers everytime i play.

so either i figure out which size pin my schon has and make sure i request that pin from the new shaft maker, or i order a blank and send it to a cuemaker and let them fit it for me.

the whole point of this whole thing, as ive said a few times, is I want TO BUY A NEW SHAFT FOR MY SCHON AND I WANT TO MAKE SURE IT WILL FIT AND THIS WHOLE PROBLEM WITH THE JOINT PROTECTORS MAKES ME THINK I DONT HAVE A STANDARD SIZE 5/16 14 THREAD.

I dont want to just order a z shaft or a tiger shaft and then have to screw it on with a pair of pliers everytime i play.

so either i figure out which size pin my schon has and make sure i request that pin from the new shaft maker, or i order a blank and send it to a cuemaker and let them fit it for me.

Well don't I feel like a shithead. Sorry I missed that. If I fit a predator or a Z shaft, I would need the butt to match it. Or you can take the extra shaft and blank Z or predator and send it to Schon. All of their joints are usually interchangeable according to the pins they used. Real sorry I missed the shaft part, If I do the job, the price is on my web site under cue repairs.

ok mike thanks lol......ill check out your sight and get back to you once i figure out which shaft im goin with