I am starting to make a shaft saw machine. I have a couple of questions.

1) Is there a good way to cut Aluminum? Bandsaw/chopsaw

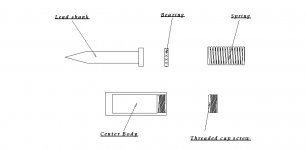

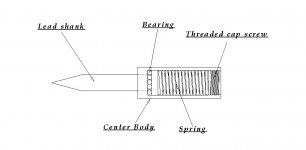

2) Sprind Loaded centers (Where do you buy them?)

3) bearing/gear box for the end of the 3/8 threaded rod, where do you buy those? If anyone has any plans/diagrams or any suggestions (lessons learned) of what to do or not, I would appreciate it.

Thanks,

Glenn

1) Is there a good way to cut Aluminum? Bandsaw/chopsaw

2) Sprind Loaded centers (Where do you buy them?)

3) bearing/gear box for the end of the 3/8 threaded rod, where do you buy those? If anyone has any plans/diagrams or any suggestions (lessons learned) of what to do or not, I would appreciate it.

Thanks,

Glenn