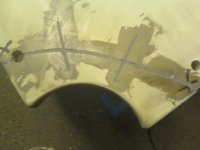

I recently was given a great set of GC4 slates, with one hitch. The corner pocket had a crack running diagonally across on the foot. I have used this technique once before to fix a side pocket antique slate that someone decided to lift without unbolting. On the antique, it needed new backing wood so I did the following on both sides. I use PC-7 which is a metall based epoxy. The backing on the GC4 slate was in great shape so I tried it just on the top. The process is listed below..

1) Identify shape of crack, break slate clean if you need.

2) Grind some clearance grooves were slate matches, along with at least 1/4 chamfer on top surfaces to fill.

3) Use something flat to bolt 2 slate pcs to after initial epoxy application, tap with mallet to fit and take air bubbles out.

4) Once seam is attached, fill chamfer with PC7 as well, grind down and stone flat.

5) Reinforce joint by using 8-32 threaded rod as rebar, use 1/8" diamond router.

6) Grind just above the slate surface with angle grinder and then use a flat object with 80-120 grit paper to plane flat. I used a large angle block because it was close. Prefer to use 18x12x4 granite surface plate with paper on finished side.

Let me know what you think..

Rob

1) Identify shape of crack, break slate clean if you need.

2) Grind some clearance grooves were slate matches, along with at least 1/4 chamfer on top surfaces to fill.

3) Use something flat to bolt 2 slate pcs to after initial epoxy application, tap with mallet to fit and take air bubbles out.

4) Once seam is attached, fill chamfer with PC7 as well, grind down and stone flat.

5) Reinforce joint by using 8-32 threaded rod as rebar, use 1/8" diamond router.

6) Grind just above the slate surface with angle grinder and then use a flat object with 80-120 grit paper to plane flat. I used a large angle block because it was close. Prefer to use 18x12x4 granite surface plate with paper on finished side.

Let me know what you think..

Rob