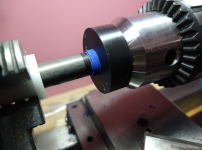

Here is my setup, the rear support is slide-able, and I can do one piece cues with it if I take the collet out of the bearing. I also recently took the gear drive for the power feed out, and modified it to use a windshield wiper motor with a PWM control and a reversing switch so I can control the feed rate independently from the lathe speed, and less wear/tear on the drive gears

.

.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metal lathe for tips/Ferrule?

- Thread starter PracticeChampion

- Start date

Here is my setup, the rear support is slide-able, and I can do one piece cues with it if I take the collet out of the bearing. I also recently took the gear drive for the power feed out, and modified it to use a windshield wiper motor with a PWM control and a reversing switch so I can control the feed rate independently from the lathe speed, and less wear/tear on the drive gearsView attachment 616155View attachment 616157View attachment 616159View attachment 616160.

Thanks, this is exactly how I'm going about it, except I put my cuesmith to the left and am going to use that lathe bed, it will also allow full length cues. The mini lathe bench will be height adjustable.

And not trying to H/J the thread but could you also post pics of the mods to the drive gear/wiper motor, etc. I've been setting up my hightower bench and have been moving/adding/modifying switches and switch locations, hopefully it will give others ideas.

PracticeChampion

Well-known member

Sidr

SideIs the second picture a top view or a side view photo?

PracticeChampion

Well-known member

LoL please high jack, I'm learningThanks, this is exactly how I'm going about it, except I put my cuesmith to the left and am going to use that lathe bed, it will also allow full length cues. The mini lathe bench will be height adjustable.

And not trying to H/J the thread but could you also post pics of the mods to the drive gear/wiper motor, etc. I've been setting up my hightower bench and have been moving/adding/modifying switches and switch locations, hopefully it will give others ideas.

PracticeChampion

Well-known member

I got the tail stock figured. I took an old set of feeler gauges and cut a few different sizes into strips for shims. Ended up having to shim it up 13 thousandths to hit center

Using your brain is a dangerous thing on this forum.I got the tail stock figured. I took an old set of feeler gauges and cut a few different sizes into strips for shims. Ended up having to shim it up 13 thousandths to hit center

LoL please high jack, I'm learning

Me too. I've been making major changes in my garage the last few months, I should be posting some pictures in the next few days so I can get some ideas to wrap up the lathe bench, look for something this weekend.

Forgot all week, here's what I ended up with , it's rigid sturdy mobile and most importantly the correct height to the centerYou got any pictures of what your using to hold joint end

Attachments

PracticeChampion

Well-known member

Currently I just started stacking foot long 2x4 and screwing together as I stack, that along with a few 1/8" paneling cut to fit and a piece of dovetail on top of all that with a steady rest and its working good for the few test rides I gave old shafts.Forgot all week, here's what I ended up with , it's rigid sturdy mobile and most importantly the correct height to the center

Now just gotta get a permanent bench built and bolt everything down solid in the wifes she shed LoL

Attachments

Edge Technologies makes a device to align headstock to tailstock. It’s a device that looks like a red tub. I think there are still video’s online that show you how to use it. Best $50 I’ve spent to maintain my lathe.Question for you guys... I made a tip centering tool and while trying out I noticed it was off center just a bit so I left just a little titty in the center of a cut and put the centering tool in the tail post to check where it was falling and as you can see it's off just a tad. Is this the nature of a cheap lathe or is there something I can do about it.

It cuts to center great though.

PracticeChampion

Well-known member

Ill check it out but I believe it's good to go now that I shimmed it. Thanks thoughEdge Technologies makes a device to align headstock to tailstock. It’s a device that looks like a red tub. I think there are still video’s online that show you how to use it. Best $50 I’ve spent to maintain my lathe.