SSDiver2112

Escott Cues

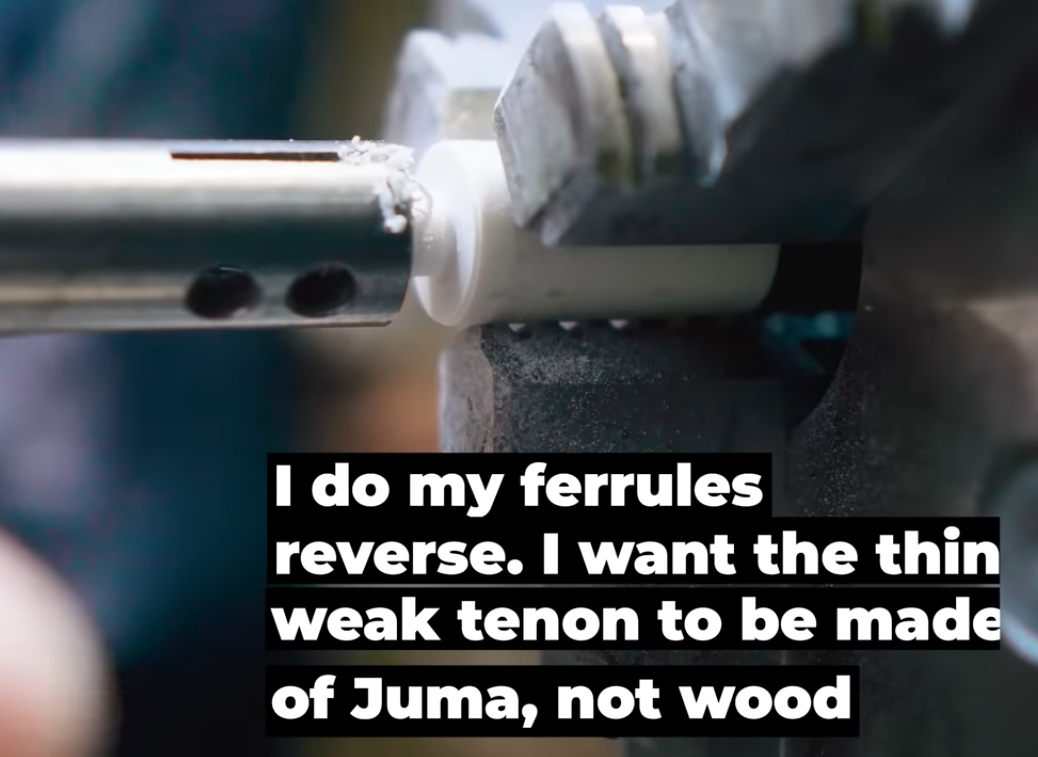

While watching the latest Studiotronics cue making video I saw that he puts the tenon on the ferrule and screws it into the shaft. I know the carbon fiber shafts have a similar design, but I hadn't heard of this on a wooden shaft. Is this technique common or is he pioneering his or a new idea? Does it have any benefit for a wood shaft?