pagaspoling

Member

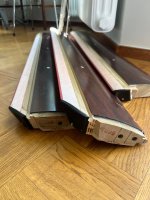

I recently got a hold on a GC4 with standard specs and I would like to extend the subrail, change the pocket angles and maybe change from SuperSpeed to another cushions. Since I live in Europe and don't have any good table mechanics around I have to do it by myself.

I would like to have 4 1/4 pockets and I dont want them to rattle so I think I will go with 141° angles. I haven't decided on down angles yet, the shelf are standard for brunswick (pretty shallow) so if a max out with 15° maybe this will make the pockets to forgiving?

I don't want to cut in the original rails so

my idea is to glue on the subrail extensions and the cut them to my chosen specs. What material would be best to use? Can I use plywood or is there a risk of the plywood splitting if it is cut diagonal? Can I use solid wood instead?

I'm planning to build four jigs in order to cut everything in an miter saw.

I would like to have 4 1/4 pockets and I dont want them to rattle so I think I will go with 141° angles. I haven't decided on down angles yet, the shelf are standard for brunswick (pretty shallow) so if a max out with 15° maybe this will make the pockets to forgiving?

I don't want to cut in the original rails so

my idea is to glue on the subrail extensions and the cut them to my chosen specs. What material would be best to use? Can I use plywood or is there a risk of the plywood splitting if it is cut diagonal? Can I use solid wood instead?

I'm planning to build four jigs in order to cut everything in an miter saw.