I'm running an experiment on doing a better job on aligning points and veneers. But I'm still screwing up. I will show my technique and how far misaligned the points are. I've been using a glueing fixture to help in aligning the center line but it still is off. I'm going to have to build another glueing fixture that is more accurate. In the photos I scribed some pencil line to locate the points, most of them aligned but one did not. I thought I was careful when glueing it up but obviously I was mistaken again. hehehe, I will post more photos when I try again.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

experiment on point and veneer alignment

- Thread starter Ernie eyocues

- Start date

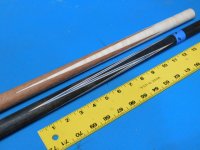

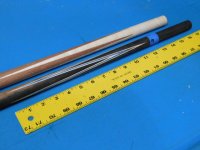

better photos of the misalignment of the points.

Hard Knock Cues

Well-known member

I'm an amateur but couldn't you adjust that by tweaking the center point a little while turning it down?

I think that is a method used on a cue with points and an a joint. I'm not sure if that process will start to tweak the bottom points now being a full splice cue with veneers. You would think that it has potential to unintentionally adjust the bottom points then.I'm an amateur but couldn't you adjust that by tweaking the center point a little while turning it down?

This is my second mistake. My glueing fixture is misaligned. Glueing non-veneered full splice blanks works just fine because I can adjust the centerline so the top of the points will align. But when aligning the veneered points is off. Sometimes things align if I get lucky and the centerline is aligned. I going to build another glueing fixture and hopefully it will be more accurate.

Yes, all you need to do is adjust the center point under the tip of the point. But unless you the centerline of the veneer section is in line with the turning center and all the veneer stacks are the same thickness and all the glue is cleaned up in the vee section, then maybe the points of the veneers will line up. With my standard non veneer blanks, if the center is moved by .01" then the tip will move by .24" on one side and .24" on the other side, the points will be off by .48". I think what needs to be done is centerline thru the veneered section needs spin on the same axis as the turning axis. This all could be just a bunch of crap because I might be wrong about this whole thing of aligning the veneers.I'm an amateur but couldn't you adjust that by tweaking the center point a little while turning it down?

photos of one method of adjusting the points.

Looks interesting.photos of one method of adjusting the points.View attachment 779162View attachment 779163View attachment 779164View attachment 779165

What is it?

hi Michael, wow, sometimes my brain doesn't keep up with my thoughts. This is an adjustable center. The 1/4" screw is screwed into the joint end. Then I make an initiate turn and then I can adjust the center by loosening the nuts and slide the plate until the points align. I hope that helps. I have a tuff time trying to explain my thoughts. English is my first language, hehehe.Looks interesting.

What is it?

Understood perfectly.hi Michael, wow, sometimes my brain doesn't keep up with my thoughts. This is an adjustable center. The 1/4" screw is screwed into the joint end. Then I make an initiate turn and then I can adjust the center by loosening the nuts and slide the plate until the points align. I hope that helps. I have a tuff time trying to explain my thoughts. English is my first language, hehehe.

If it works. GREAT!

I'm a little skeptical about it but that's just me.

I have an actual adjustable center, I bought 20 years ago.

Expensive sucker. Cost me $500 back then.

. I bought it anticipating a problem like your having.

Lol

I've never used it.

When I work with squares, I made a sled to hold the squares, and it's adjustable to do straight cuts or tapers working off the centers on my band saw.

Maybe something like that would help you.

Because you wouldn't have to find a center later. Easy eneogh to build one.

Maybe.

Attachments

greetings Michael, What a clever idea. I never thought of making the centers first then creating the square around the centers. Pure genius. I'm a stubborn old man that like to start projects without a lot of input because it tends to contaminate my design process. But this idea would have solved and save a lot of time. I guess, it's never too late to learn.Understood perfectly.

If it works. GREAT!

I'm a little skeptical about it but that's just me.

I have an actual adjustable center, I bought 20 years ago.

Expensive sucker. Cost me $500 back then.

. I bought it anticipating a problem like your having.

Lol

I've never used it.

When I work with squares, I made a sled to hold the squares, and it's adjustable to do straight cuts or tapers working off the centers on my band saw.

Maybe something like that would help you.

Because you wouldn't have to find a center later. Easy eneogh to build one.

Maybe.

best regards and thanks, Ernie

oh yeah, the adjustable center does work but after building the glueing fixture the blanks were reasonably true so I could adjust the center by .003 to .010" and get the points to line up.

hi, I have seen photos of makers cutting the vee slot on a lathe, on centers. And you're right that this would keep things aligned but I just when down a different rabbit hole and was too stubborn to change until now. I have not made many cues lately, but this alignment of the veneer problem has been floating around in my mind for awhile. So I decided to try to find one solution. You are right that keeping the center lines aligned is a must. Even with that, if the veneer stack thickness and glueing the in place isn't do with great care then the points of the intermediate veneer points will vary. How much I don't know. Once again my ideas my be all wrong but just trying is all the fun.I do not normally try to put veneers in my full splice but I cut my full splice while in the rounds. This gives me the original center holes in each end. That makes the points automatically come out even.

best regards and thanks for the feedback, Ernie

If you have a center with a locking nipple on it, like a recut center. You could also do the squares on the lathe, locking the chuck for each of the 4 sides and use a straight cut with a routergreetings Michael, What a clever idea. I never thought of making the centers first then creating the square around the centers. Pure genius. I'm a stubborn old man that like to start projects without a lot of input because it tends to contaminate my design process. But this idea would have solved and save a lot of time. I guess, it's never too late to learn.

best regards and thanks, Ernie

oh yeah, the adjustable center does work but after building the glueing fixture the blanks were reasonably true so I could adjust the center by .003 to .010" and get the points to line up.

I made some changes to my fullsplice veneer technique. The alignment looks a little bit better. I hand cut the veneers and double checked the thickness before and after glueing the stack up. I also redesigned the glueing jig. The internal points seem to align a little better. If I get around to it, I will try to build a better glueing fixture. Hopefully you can see the alignment pencil marks.

I'm not a cue builder but I was shown from a good builder on method for adjusting points.

He grabbed a pack of Rolling Papers, which were always handy, and slipped one between the jaws and cue.

One paper thickness moved the culprit a fair bit.

Kinda thinking this could become a chase your tail method but?? Like I said I'm not a builder. Just a tool nerd.

He grabbed a pack of Rolling Papers, which were always handy, and slipped one between the jaws and cue.

One paper thickness moved the culprit a fair bit.

Kinda thinking this could become a chase your tail method but?? Like I said I'm not a builder. Just a tool nerd.