could 1 or 2 cuemakers post pics of what a nice square of shaft wood looks like. Obviously I play pool and even more obvious I will never make a cue. We hear the term no grain runout. So many gpi. I know what mineral spots look like but curious what a nice square of wood looks like. Maybe show good square versus one of your lesser quality pieces. I cant be the only dummy on Az who is curious to see the difference. Any help out there in cuemakers land ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

beginner needs help

- Thread starter hotrod

- Start date

could 1 or 2 cuemakers post pics of what a nice square of shaft wood looks like. Obviously I play pool and even more obvious I will never make a cue. We hear the term no grain runout. So many gpi. I know what mineral spots look like but curious what a nice square of wood looks like. Maybe show good square versus one of your lesser quality pieces. I cant be the only dummy on Az who is curious to see the difference. Any help out there in cuemakers land ?

Hi,

Tomorrow Darrin Hill is coming to my shop with some hand picked select 5/4 stock clear maple planks. Before we rip and dowel them, I will take some pics of the boards, squares and dowels for you to see the things you are asking about.

Rick

Hi,

Tomorrow Darrin Hill is coming to my shop with some hand picked select 5/4 stock clear maple planks. Before we rip and dowel them, I will take some pics of the boards, squares and dowels for you to see the things you are asking about.

Rick

Thanks, I would like to learn

Hi,

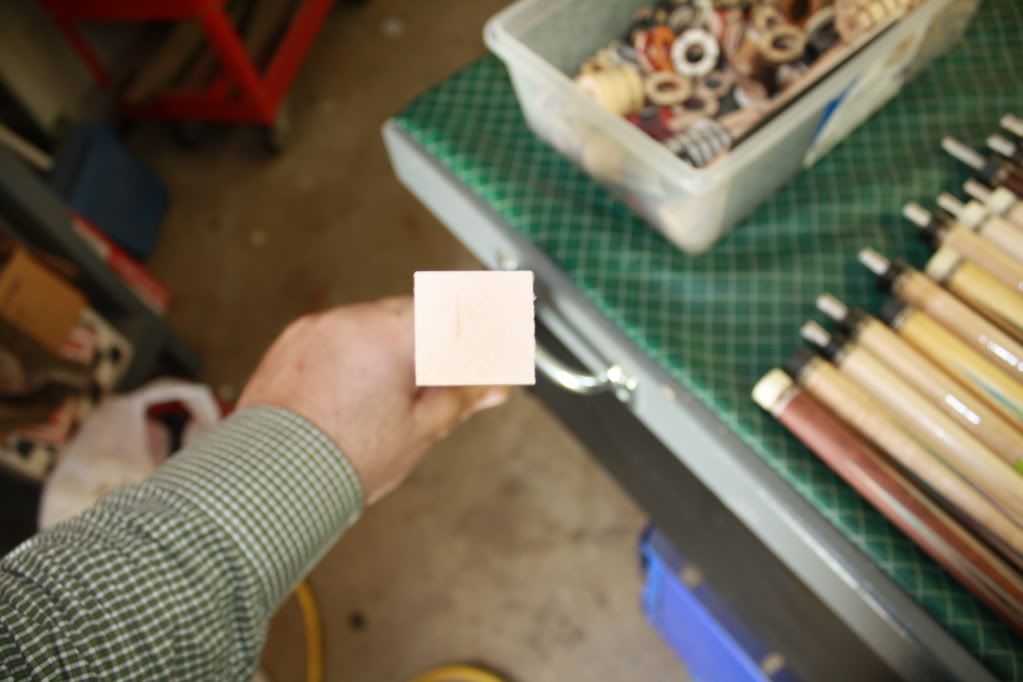

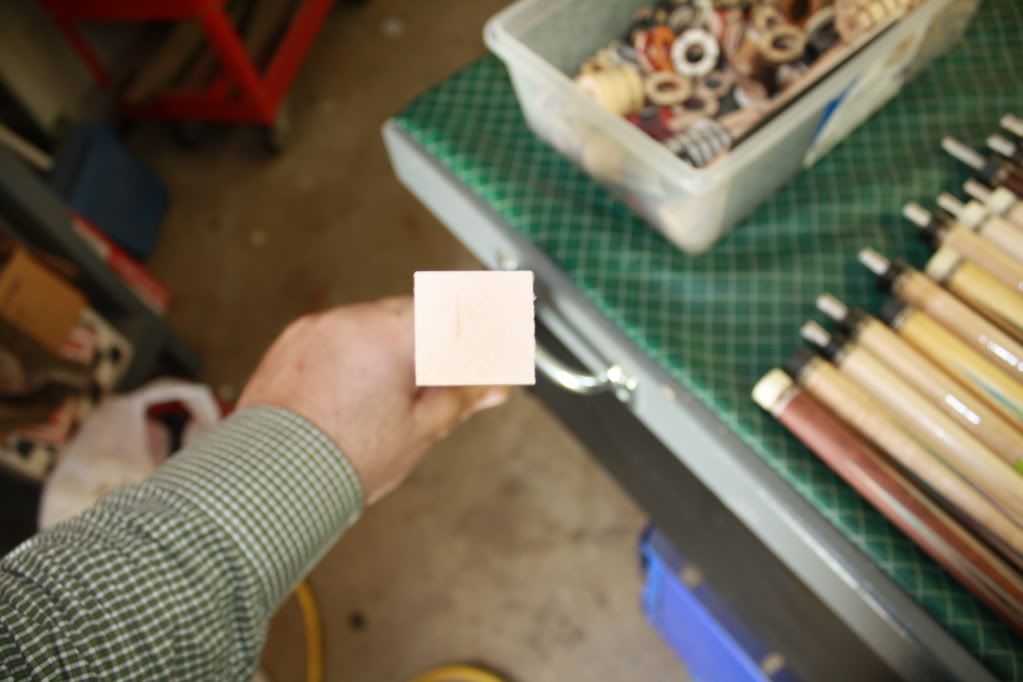

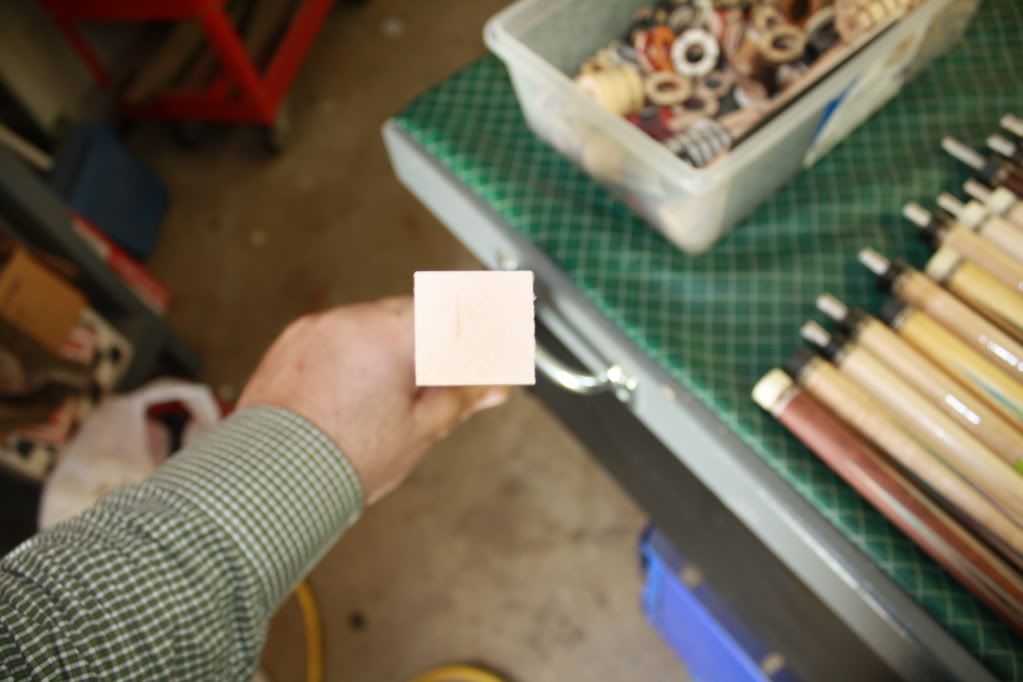

The pics did not turn out too good because I did not know how to turn the flash off with the close up..

I hope you can see the grain.

You want to collate heavy boards with straight grain with more focus on heavy. Density is more important that GPI, IMO. I don't pick pieces with less than 12 gpi as a rule. We had some that read 34 GPI ion a 5/4 plank and was real heavy yielding 11 oz 1" dowels @ 30". Some of those shafts at final will be 5 oz with my stiff spine parbolic taper @ 13MM.:shocked2:

Darrin went through 200 plank just to get 2 boards. Like Eric Crisp has posted here it would be impossible for a mill to deliver what an "in the know cue maker" needs for his stock as it is very sparse. You can't get good wood buying from a merchant. You must do the work. You must buy planks. If you don't believe me read DPK's book on cue making.

I buy the kiln dried 5/4 stock from the UP and about every 3 month I get a few boards by cherry picking from a couple hundred. My stock is up to over 600 tapered pieces at .950 at the joint and I still want more for the future.

Good Picking,

Rick

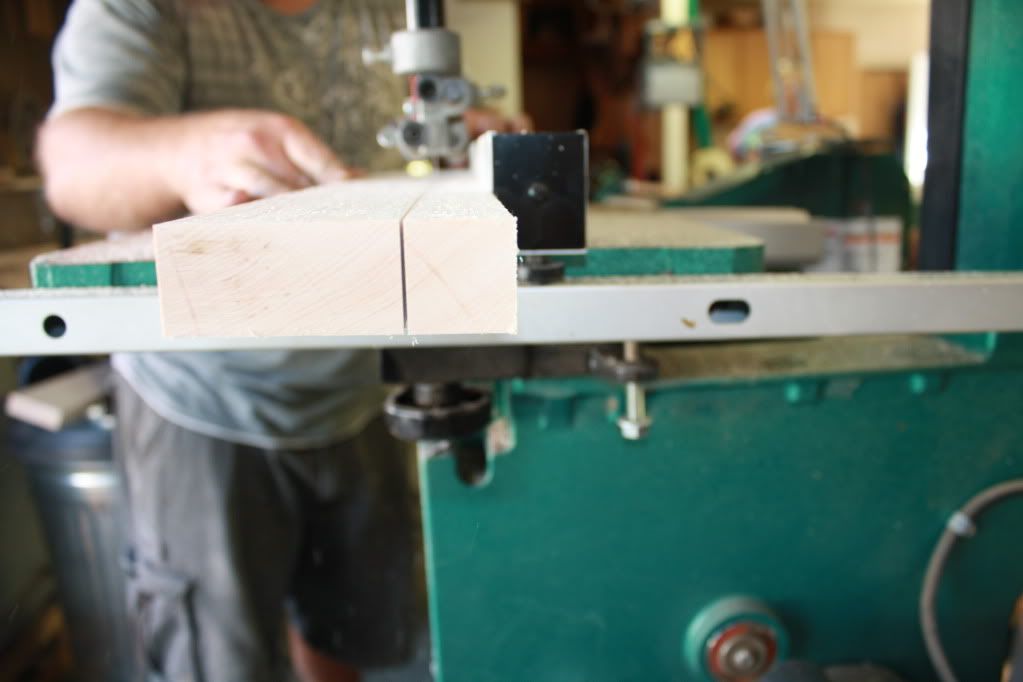

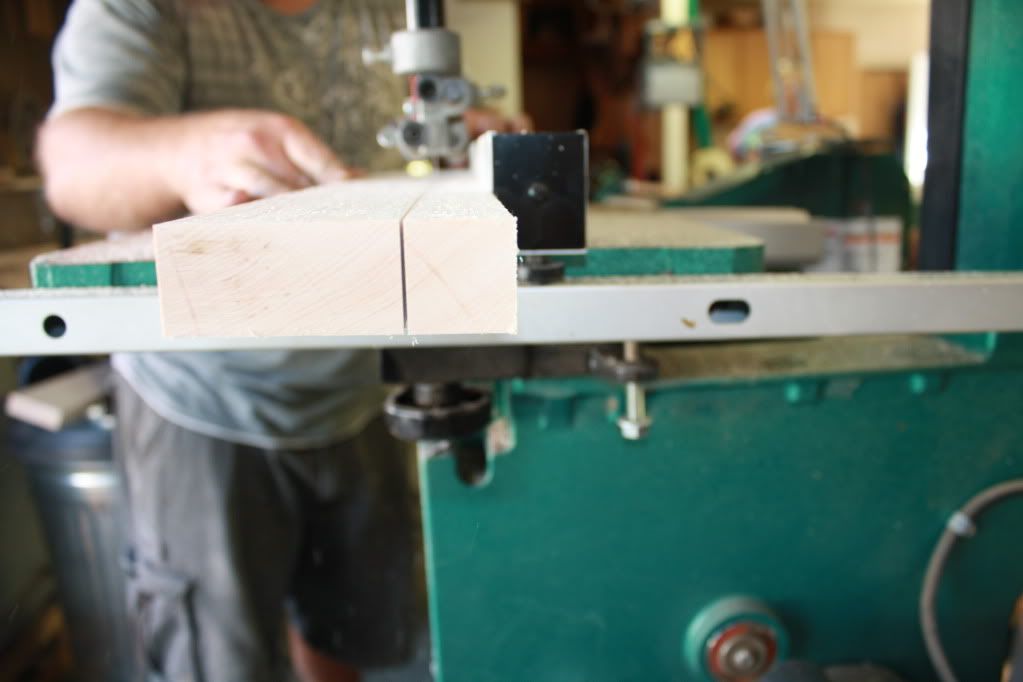

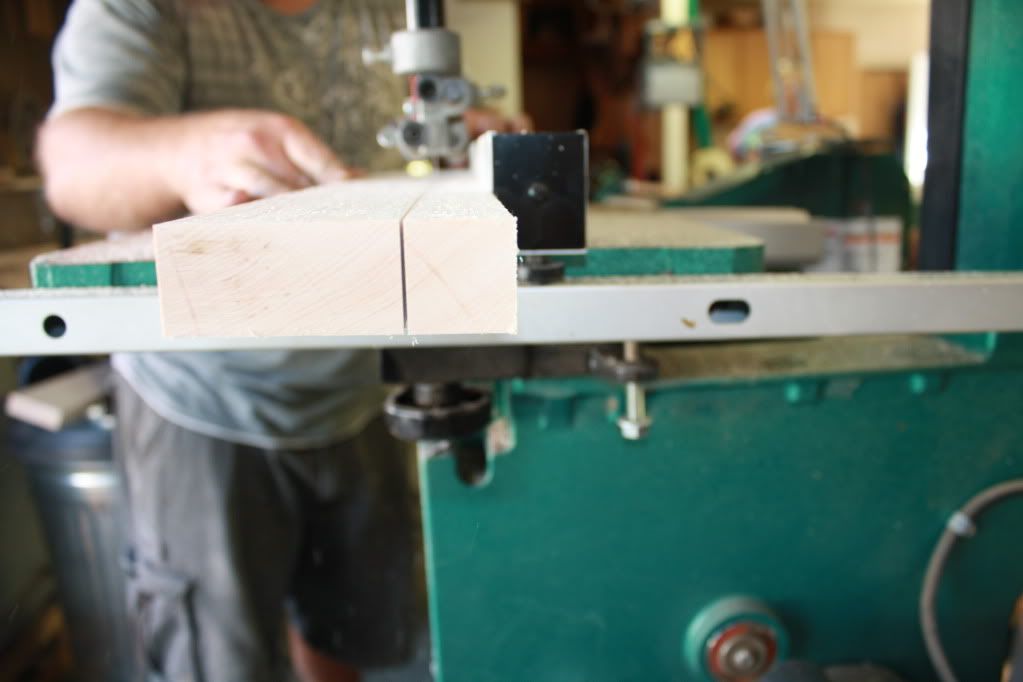

Cue Master Hill cutting in our shop.

The pics did not turn out too good because I did not know how to turn the flash off with the close up..

I hope you can see the grain.

You want to collate heavy boards with straight grain with more focus on heavy. Density is more important that GPI, IMO. I don't pick pieces with less than 12 gpi as a rule. We had some that read 34 GPI ion a 5/4 plank and was real heavy yielding 11 oz 1" dowels @ 30". Some of those shafts at final will be 5 oz with my stiff spine parbolic taper @ 13MM.:shocked2:

Darrin went through 200 plank just to get 2 boards. Like Eric Crisp has posted here it would be impossible for a mill to deliver what an "in the know cue maker" needs for his stock as it is very sparse. You can't get good wood buying from a merchant. You must do the work. You must buy planks. If you don't believe me read DPK's book on cue making.

I buy the kiln dried 5/4 stock from the UP and about every 3 month I get a few boards by cherry picking from a couple hundred. My stock is up to over 600 tapered pieces at .950 at the joint and I still want more for the future.

Good Picking,

Rick

Cue Master Hill cutting in our shop.

Last edited:

shaft wood dowels

Rick thanks for the pics and effort. Info very helpfull. Cool checking out pics of the different shop equipment. Thanks RodHi,

The pics did not turn out too good because I did not know how to turn the flash off with the close up..

I hope you can see the grain.

You want to collate heavy boards with straight grain with more focus on heavy. Density is more important that GPI, IMO. I don't pick pieces with less than 12 gpi as a rule. We had some that read 34 GPI ion a 5/4 plank and was real heavy yielding 11 oz 1" dowels @ 30". Some of those shafts at final will be 5 oz with my stiff spine parbolic taper @ 13MM.:shocked2:

Darrin went through 200 plank just to get 2 boards. Like Eric Crisp has posted here it would be impossible for a mill to deliver what a in the know cue maker needs for his stock as it is very sparse. You can't get good wood buying from a merchant. You must do the work.

I buy the kiln dried 5/4 stock from the UP and about every 3 month I get a board or two by cherry picking from a couple hundred. My stock is up to over 600 tapers at .950 and I still want more for the future.

Good Picking,

Rick

Cue Master Hill cutting in our shop.