thestickman

New member

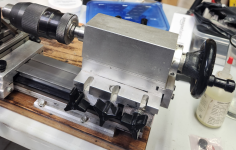

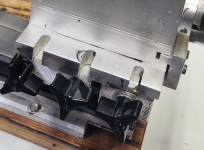

Hi. I am new to the cue lathe game. I bought one second hand so that I could do my own tips, and maybe help out local players with it since no one else has one in this area. Fast forward 6-7 months and I'm not so bad at it now. The lathe is a cue smith midsize, but it has some mods. Everything is on some kind of riser so that it sits at the same height as the deluxe cuesmith would be at. Everything works great, except I have a tailstock alignment issue. Part of that problem is the tailstock is one the previous owner made, it's not the cuesmith stock lever style. I'm at a crossroads where I either buy the correct tailstock from cuesmith, or I figure out how to do an alignment and just keep using this.

Can someone explain how to do it?

Can someone explain how to do it?