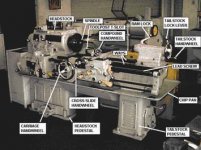

I am considering building my own cue lathe.

I'd very much appreciate it if guys that have their own equipment would post detailed pics.

Especially interested in collets, tailstocks and steadys.

Thanks,

Dave

I'd very much appreciate it if guys that have their own equipment would post detailed pics.

Especially interested in collets, tailstocks and steadys.

Thanks,

Dave