To the OP:

Are you thinking of just doing the pocket castings? If so, rethink it: it looks awesome when ALL

of the metal trims are the same. Dont cheat yourself. I use the Vein style of powder coating.

It has a textured finish and allows the applicator to build up the powder on scratches an blemishes.

Make sure to get the clear coat, will look great and last a very very long time.

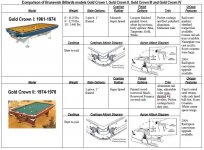

Attached pic is Nickel Vein and that is a GC1 w/ new everything. Black formica and MOP inlays!

TFT

Are you thinking of just doing the pocket castings? If so, rethink it: it looks awesome when ALL

of the metal trims are the same. Dont cheat yourself. I use the Vein style of powder coating.

It has a textured finish and allows the applicator to build up the powder on scratches an blemishes.

Make sure to get the clear coat, will look great and last a very very long time.

Attached pic is Nickel Vein and that is a GC1 w/ new everything. Black formica and MOP inlays!

TFT