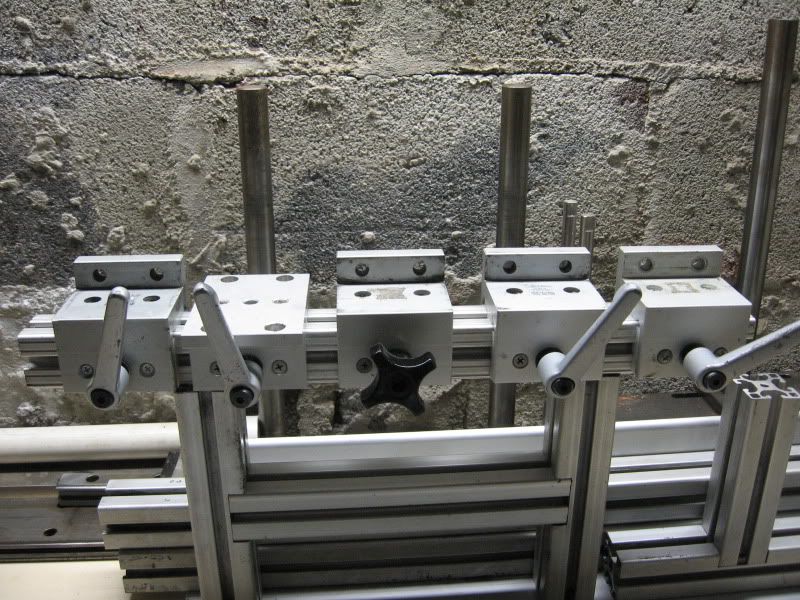

Since this thread seems to be crossing between sanding, finishing, and tipping machines, I thought I would show my old setup (before I got a lathe). It was relatively cheap, and gives you the option of using a Sherline headstock, which sometimes come up on eBay for cheap.

The mounting plate is a Sherline mounting plate which I got from A2ZCNC.com - but I just went to A2ZCNC looking for it and I can't find it - sorry about that.

I also bought a 3/8" tool holder that screws onto the Sherline spindle, but the company I bought that from VCSHobbies.com doesn't seem to stock Sherline parts anymore either. In any case, my maintenance pins have a 3/8" shaft, so I could support the joint end of a shaft using them.

I hand built a Lexan/Plexiglass "tailstock" with a simple bearing mounted in it to hold the tip end using a delrin collet.

I don't claim this particular setup can be used for anything very heavy duty, but it's presented as another option for spinning a cue and how Googling the Internet can help you find alternatives to the stock products.

Hope this helps someone

Gary

Very cool setup Gary. That would be a great simple setup to sell for people that just want to clean and do a tip for their personal cues.

Dave