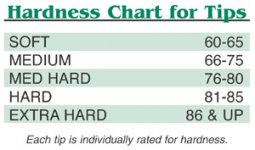

Kamui Tips seem to be what a lot of people are changing too. Mueller has this TIP Hardness Chart on their web-site.

This chart would be an older chart.

It drives me crazy trying to explain this hardness stuff.

I think I should qualify myself first before I start arguing the validity of a Durometer and measuring hardness of leather.

____________

Almost all of my childhood life and adult life has been with a material scientist/metallurgist for a father. I would work with him on many projects. Like most sons who look up to his father as an amazing role model, I have to remove my biased opinion and look at the man and his approach to analyzing any material... He has the technology to make Titanium into a industrial framing hammer that would relieve tennis elbow in the construction industry.... No metallurgist has been able to figure it out. That is one example of a brilliant man with over 160IQ...

I can go on for hours talking about his accomplishments... But I can save you the long stories... He is a published author as well.

_____________

When I first learned of the type of measuring devise used to measure hardness

Durometer I was very confused as to how this would work for leather? I have used durometers many times before and to use this "hardness tester" on a porous material made me question my understanding of leather and the billiard tip...( I was like a house cat watching a possum walk by for the first time ) It just did not connect in my head.

I understand by habit, as humans, we have a tendency to measure things so we can categorize them and give them a space in our existence. This is normal.

Lets define what the durometer is basically used for. It is used for measuring the density/hardness of plastics and rubber. Depending on the measuring "indenter" and scale used will determine a number.

Notice

what the durometer is used for... a non-porous material. Dense materials will give back accurate readings on a durometer.

The durometer will not give back an accurate reading of leather. Why? you ask. Well, indenter of the durometer, when pushed into the leather, is pushing out and relaxing into the porosity of the leather. Nothing to push against. The leather is tearing on a micro level letting the indentor take its path.

And this is where I got confused... and my father set my thinking straight. The "mechanical" physics of the leather is in question. NOT it's density. You can have a dense material and still have FLEX.(ELASTICITY)

I know that what I am writing can be upsetting some or confusing to others. Kamui has our own scale that works. based on mechanical physics.

We build our tips based on our leather processing standards, not general leather standards. We do not make tips and shuffle them into their hardness slots based on what a measuring tool tells us... No, not done that way.

If there were to be a measuring device... someone needs to invent ;-)

Here is the challenge..

You would have to create a way to

impact the tip with an object the same weight as a cue ball. Then there has to be a reaction to the impact that would register a number.

This would be the only way to tell a true number measuring the leather material.

SO, to sum up my shortest possible dissertation on this subject.

You are the best measuring device for any tip you put on your cue.

Our job, is to provide you the most consistent product on the market.

Kamui is never satisfied with the products we produce.